Injection mold for router base and injection process of router base

A technology for injection molds and routers, applied in the direction of coating, etc., can solve the problems of prolonging injection molding time, long cooling molding time, uneven mixing, etc., to ensure quality, reduce molding cycle and production costs, and ensure aesthetics and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

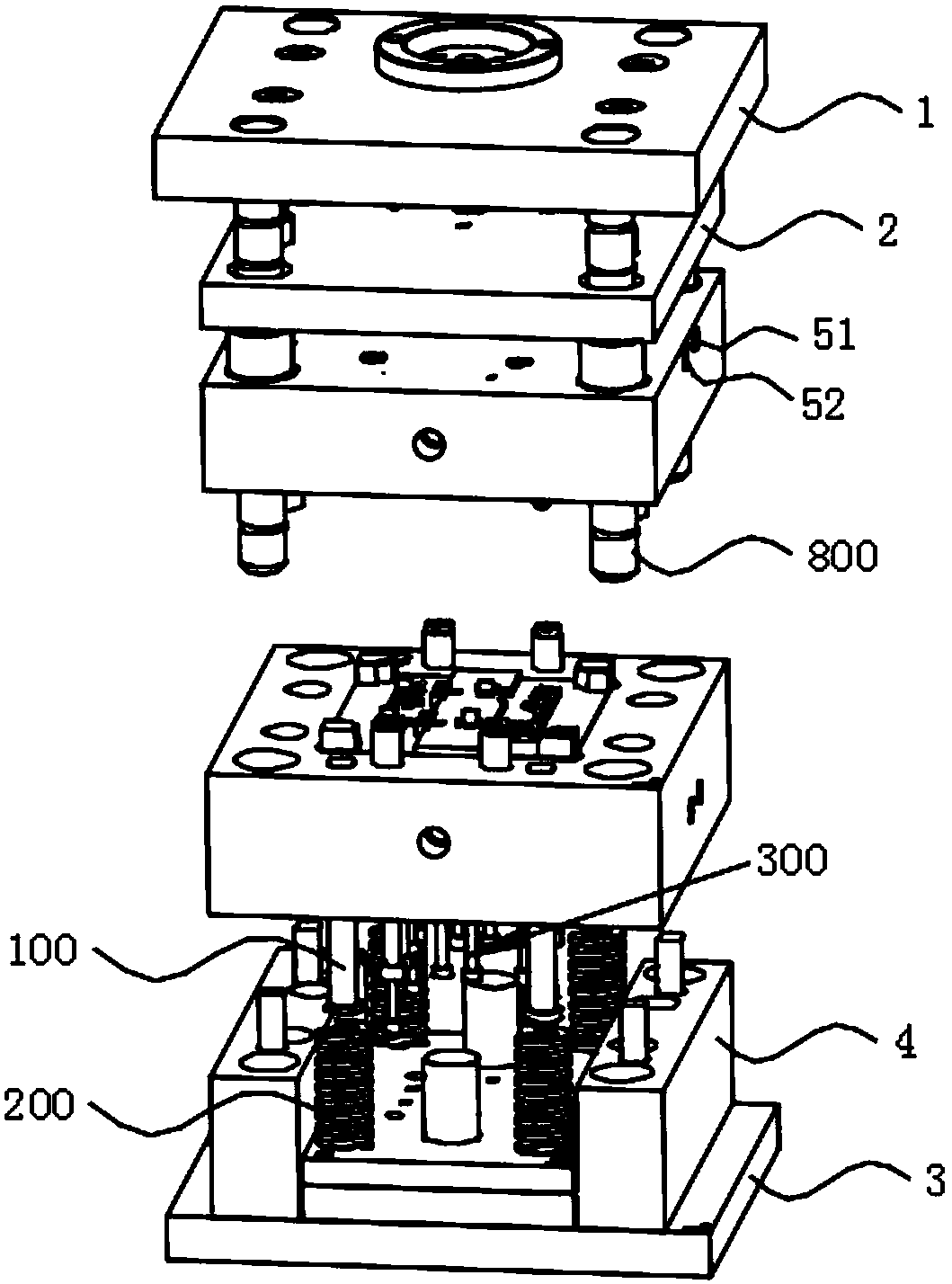

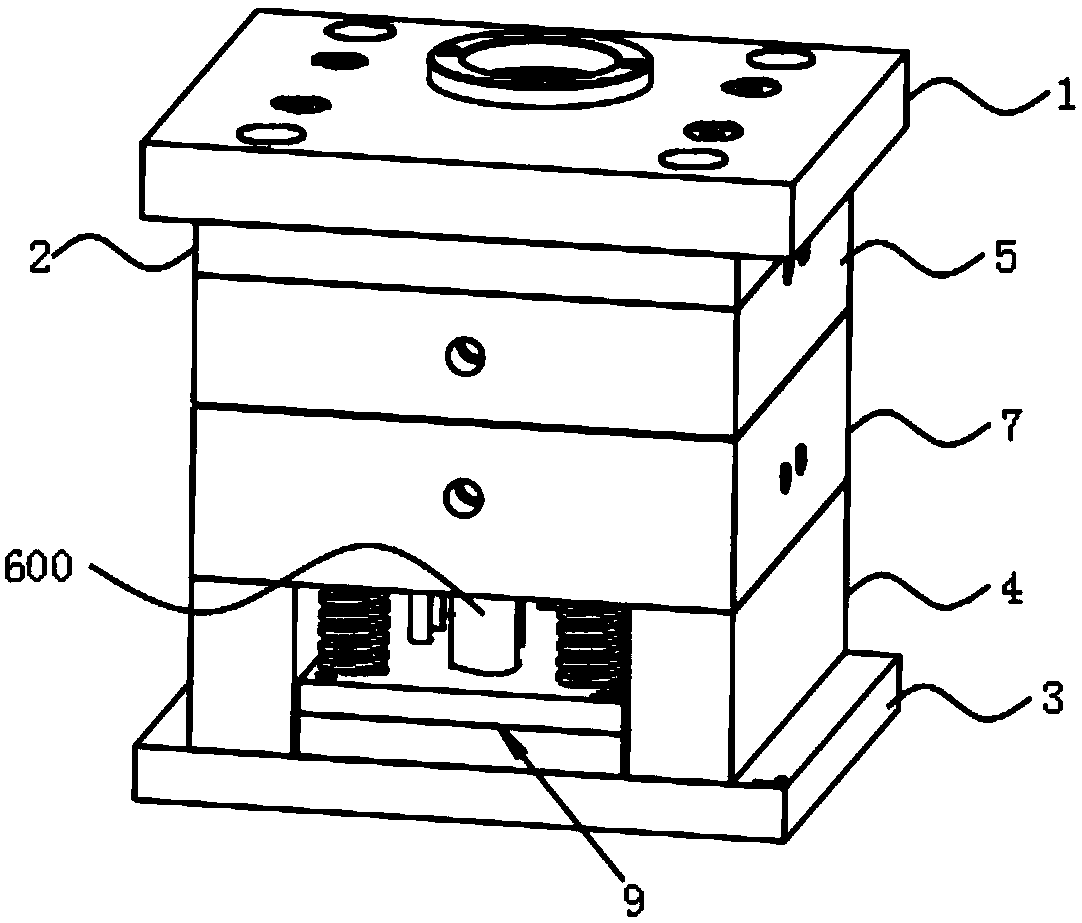

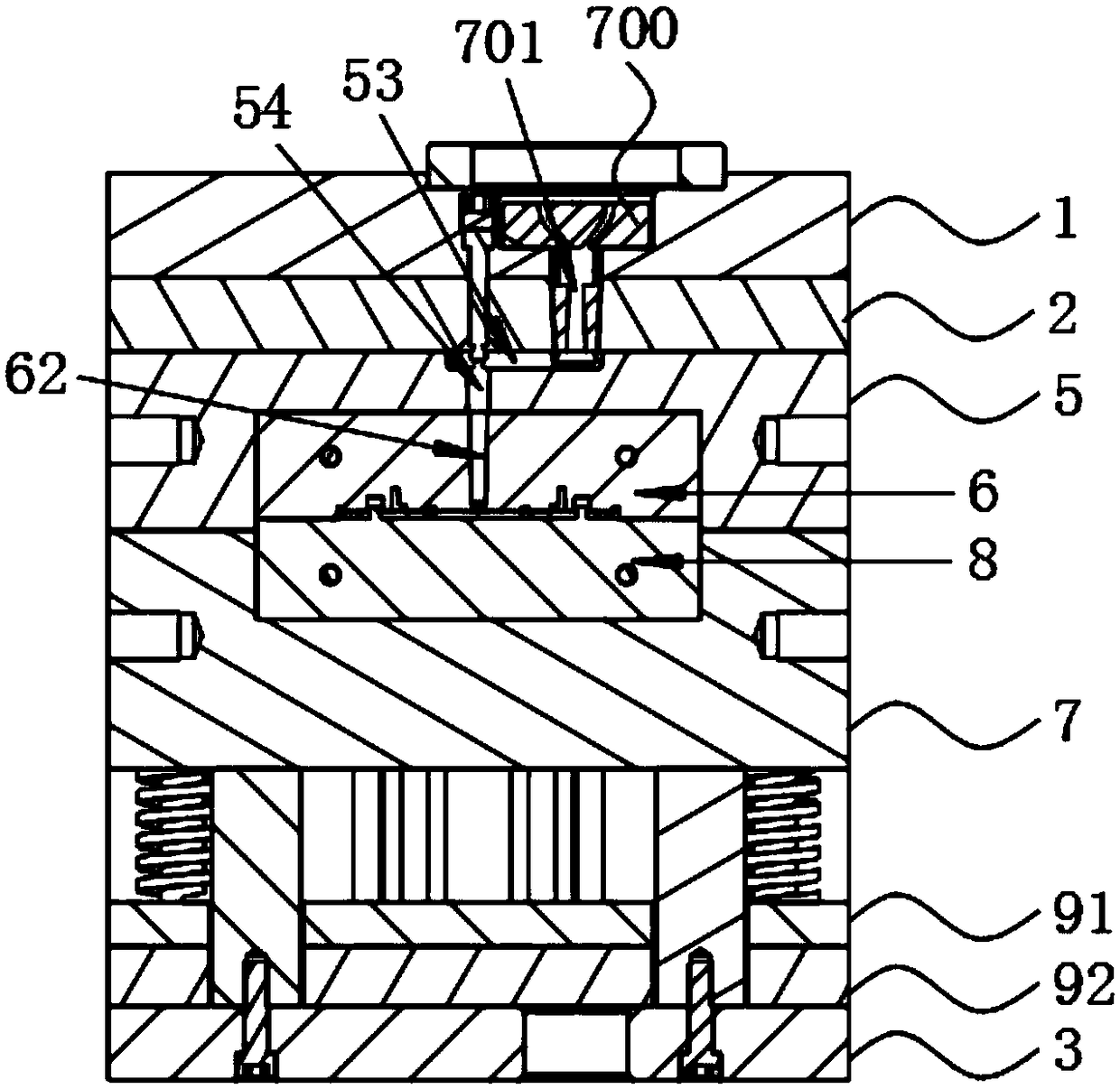

[0060] Embodiment: a kind of injection mold of router base, such as Figure 1-Figure 7 As shown, it includes a panel 1, a nozzle plate 2, a female module, a male module and a bottom plate 3, the nozzle plate 2 is located between the panel 1 and the female module, and the bottom plate 3 is provided with two die feet 4, The male module is fixed on the die foot 4;

[0061] The female module includes a female template 5 and a female mold core 6, the female template 5 is provided with the female mold core 6 near the surface of the male module, and the male module includes a male template 7 and a male mold core 8, so The surface of the male module close to the female module is provided with a male mold core 8, and a mold cavity is formed between the female mold core 6 and the male mold core 8;

[0062] The side wall of the master template 5 is provided with a master mold water inlet 51 and a master mold water outlet 52, and the master mold water inlet 51 and the master mold water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com