Aircraft leading edge anti-bird collision structure

A leading edge and bird strike technology, applied to aircraft parts, aircraft indicating devices, equipment to prevent bird strikes, etc., can solve the problems of affecting effective space, complex installation structure, low structural efficiency, etc., and achieve low cost and high structural form The effect of simplicity and structural efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

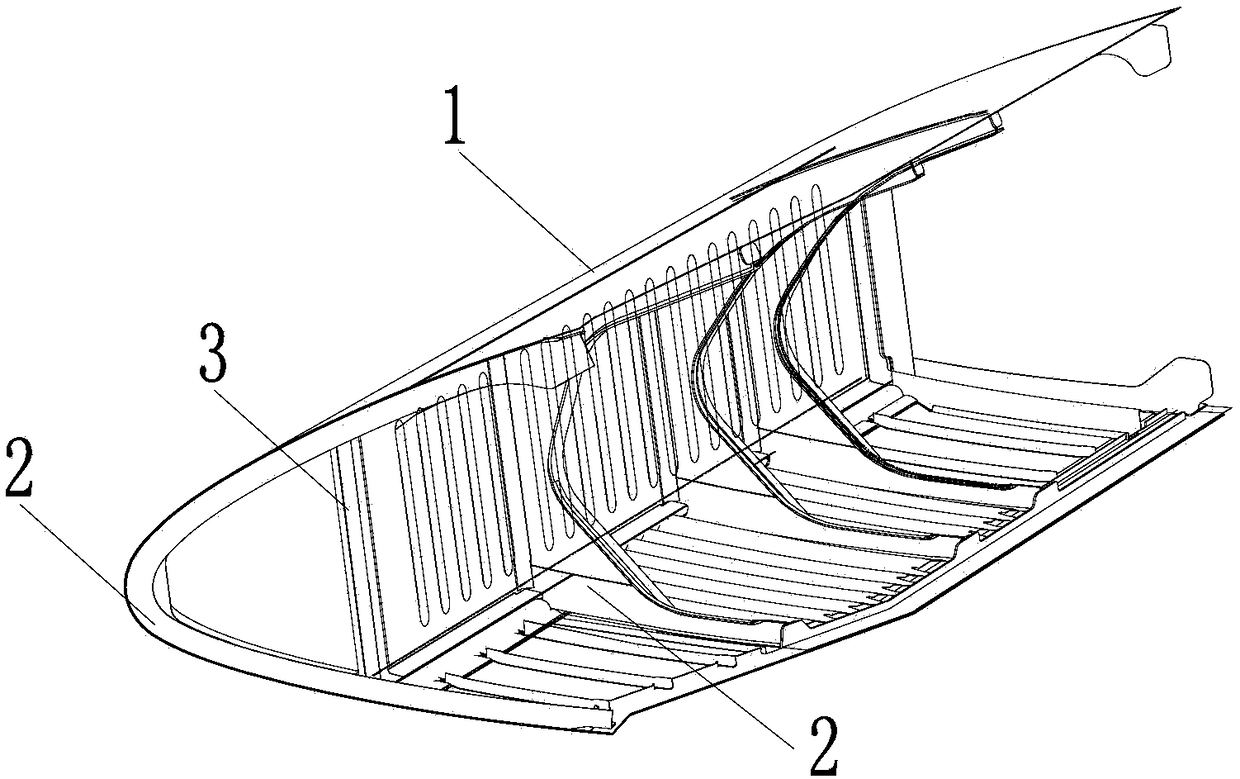

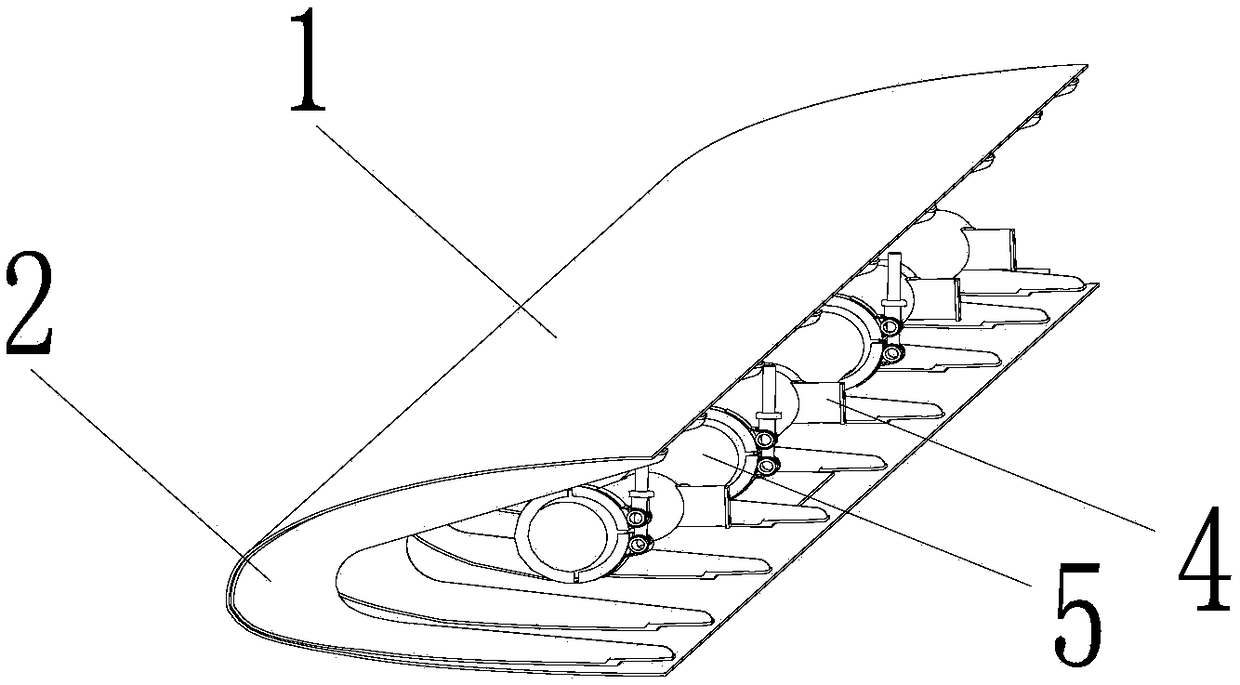

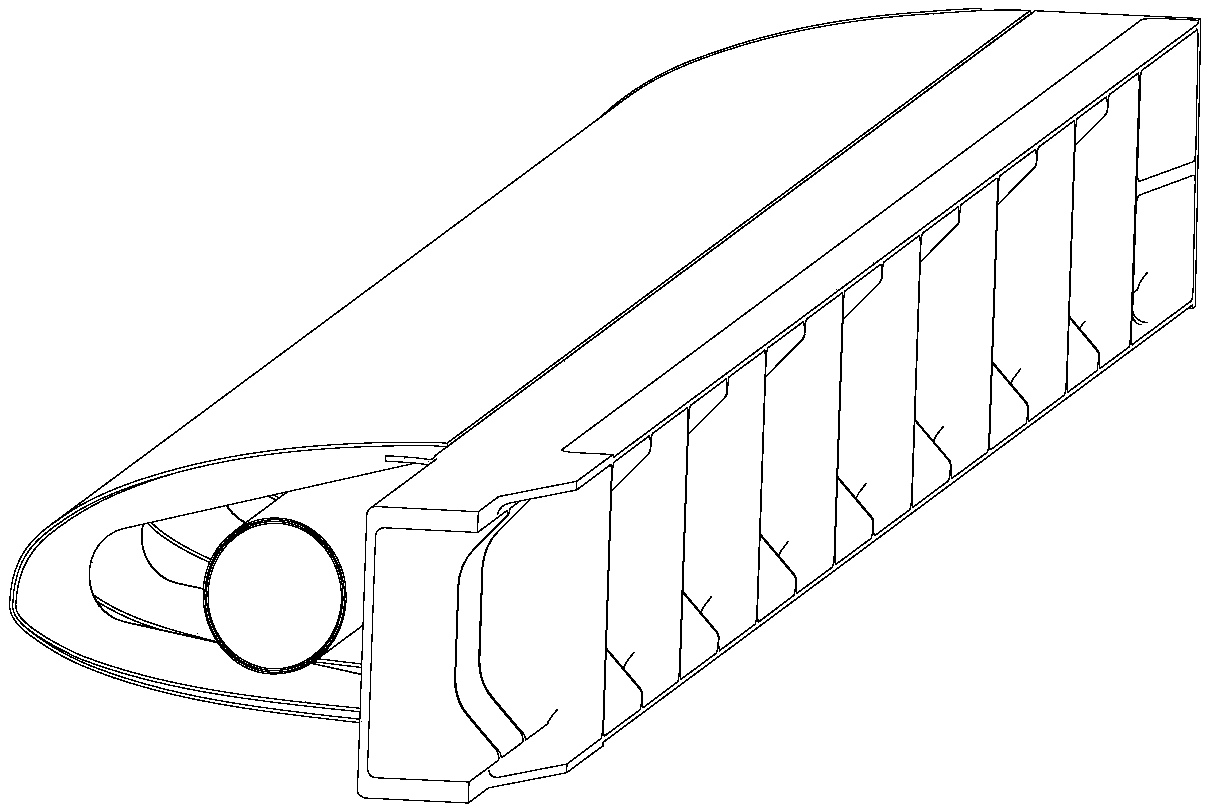

[0015] Such as figure 2 As shown, an anti-bird strike structure at the leading edge of an aircraft includes a leading edge skin 1 and a rib plate 2. In the cavity of the leading edge skin 1, a hollow thin-walled structure is installed at a certain distance from the leading edge skin 1. Energy absorbing tube 5.

[0016] The hollow thin-walled energy-absorbing pipe 5 is fixed on the beam through the bracket 4 . The bracket 4 has a bayonet matching with the hollow thin-walled energy-absorbing tube 5 .

[0017] The hollow thin-walled energy-absorbing pipe 5 is integral or segmented. The hollow thin-walled energy-absorbing tube 5 is filled with energy-absorbing material. Various types of cables are installed in the hollow thin-walled energy-absorbing tube 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com