Environmentally friendly and energy-saving mountain-shaped silicon carbide smelting tail gas recovery device and recovery method

A technology of exhaust gas recovery, environmental protection and energy saving, applied in the direction of silicon carbide, carbide, chemical industry, etc., can solve the problems of high pollution, fryer accident, high energy consumption, etc., to ensure sufficient exhaust and enhance the effect of exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

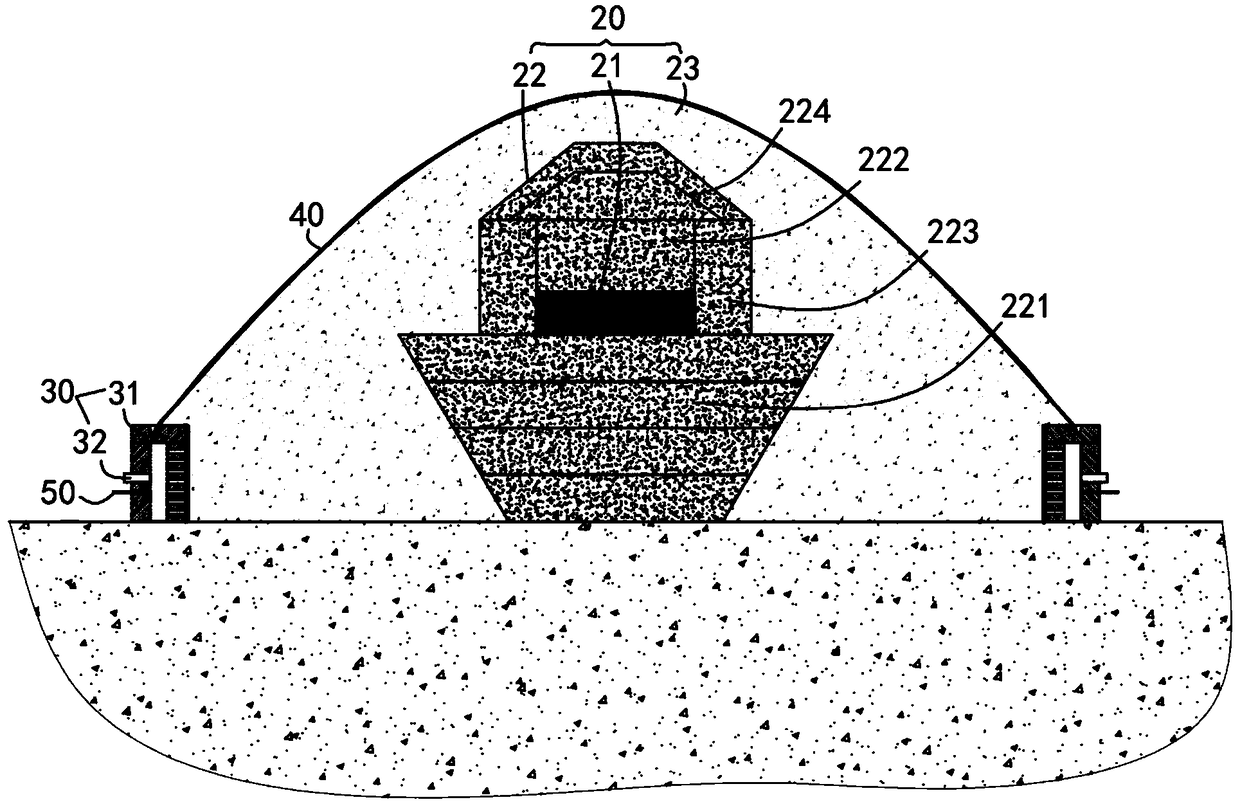

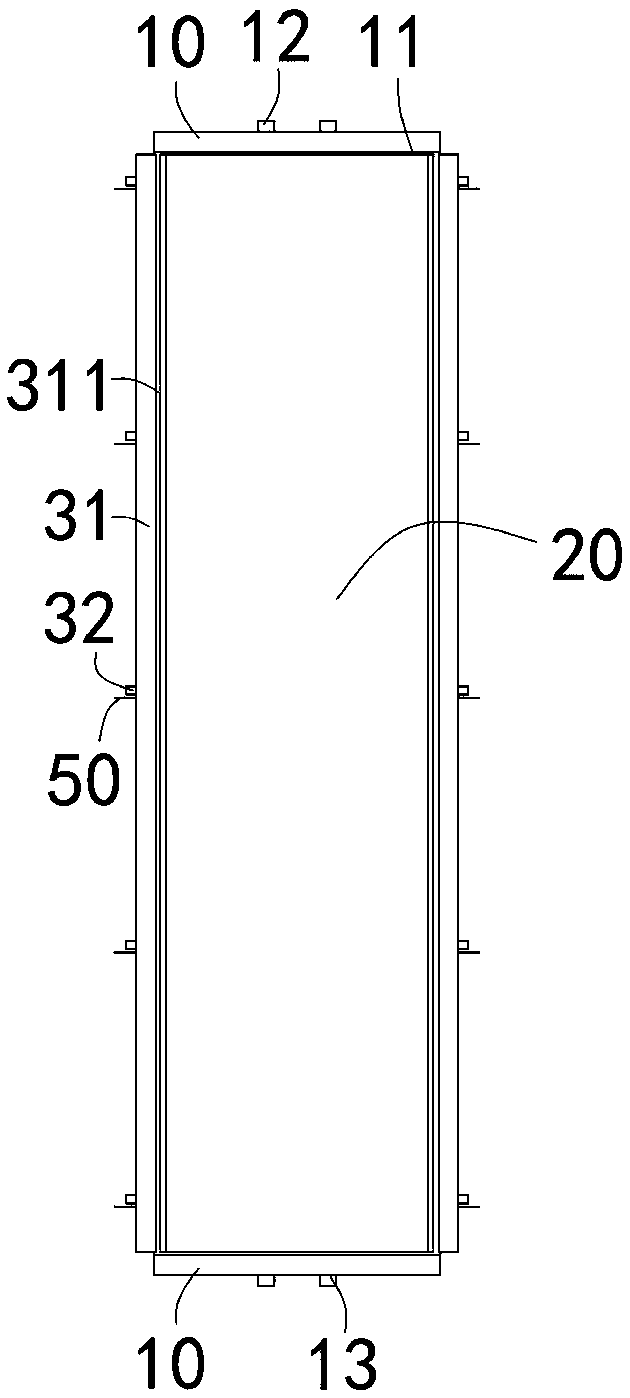

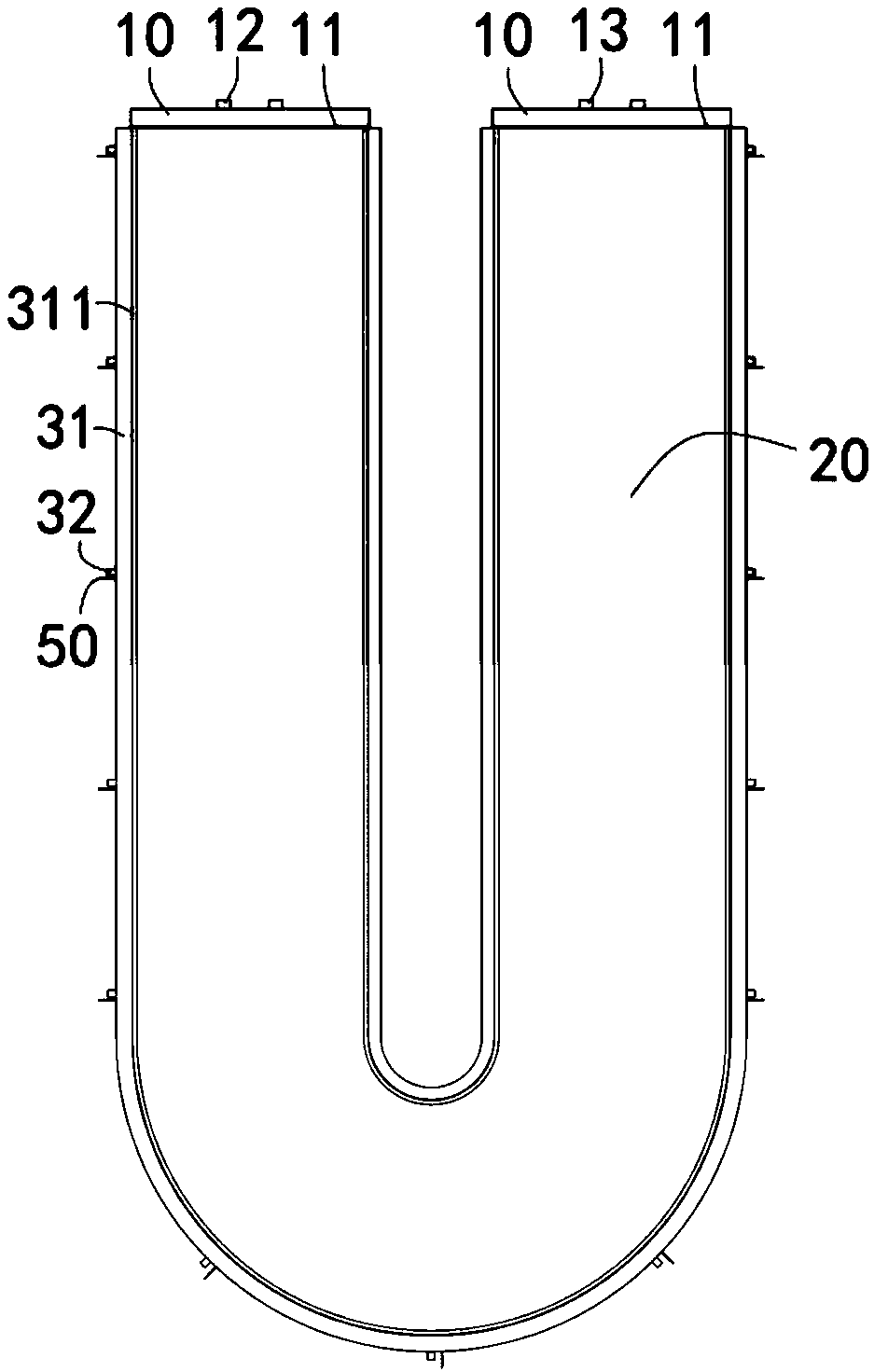

[0022] see Figure 1 to Figure 4 , the embodiment of the present invention provides an environment-friendly and energy-saving mountain-shaped silicon carbide smelting tail gas recovery device. The device has two end walls 10. A sealing groove 11, a DC positive terminal 12 is installed in the middle of one end wall 10, a DC negative terminal 13 is installed in the middle of the other end wall 10, and a reaction body 20 is connected between the two end walls 10. The reaction body 20 In a straight line or U shape, the reaction body 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com