Ventilated hose

A technology of ventilation hose and rubber layer, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., and can solve problems such as difficult installation and disassembly of ventilation hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

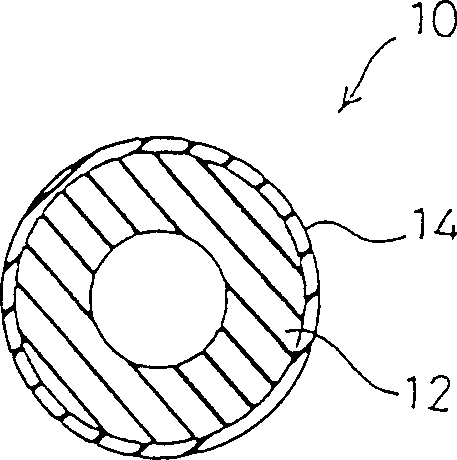

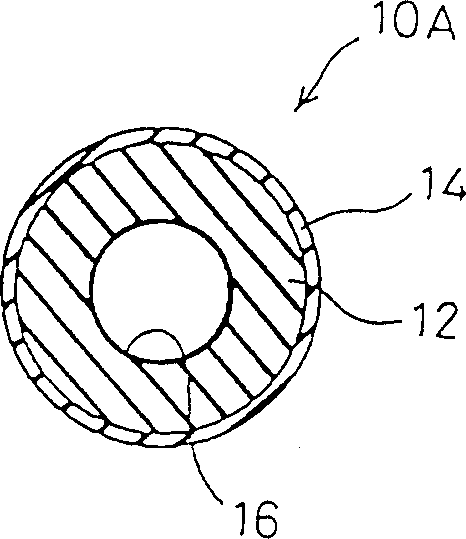

[0015] In the present invention, the first rubber layer includes an epichlorohydrin rubber. The epichlorohydrin rubber includes homopolymers and copolymers using epichlorohydrin as a unit body. As examples, they can be made from epichlorohydrin-ethylene oxide copolymer (ECO), epichlorohydrin-ethylene oxide-allyl glycidyl ether copolymer (GECO) and the like.

[0016] The second rubber layer comprises chlorosulfonated polyethylene rubber and surrounds the outer surface of the first rubber layer to a thickness of about 0.2-0.6 mm.

[0017] According to the ventilation hose with the above structure of the present invention, in order to keep its outer diameter similar to that of a conventional hose, the thickness of the second rubber layer on the outer surface of the first rubber layer is made thinner, That is, about 0.2 mm to 0.6 mm, thus ensuring that the thickness of the inner first rubber layer is similar to that of a conventional single-layer vent hose. Since the first rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com