Automatic cascade type refrigerating and circulating system with unfixedly proportioned hybrid medium

A technology of mixed working fluid and circulating system, applied in refrigerators, refrigeration and liquefaction, compressors with cascade operation, etc., can solve the problems of limited application scope, high energy consumption, and reduced evaporation temperature of high-temperature components, etc. Achieve the effect of avoiding insufficient liquid supply, ensuring normal work, and shortening cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

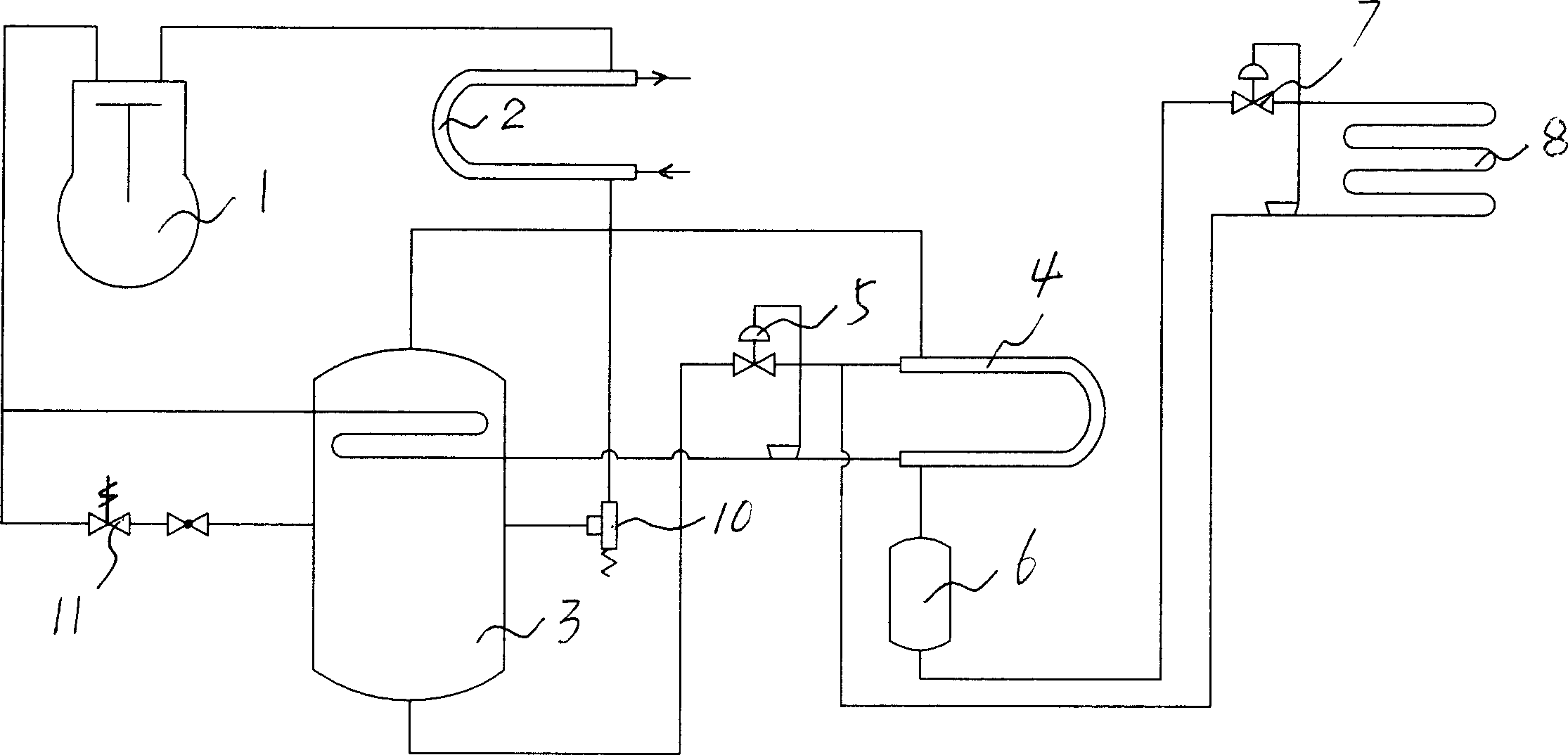

[0017] There is a compressor 1, and a decondenser 2 is connected to the exhaust port of the compressor 1, and the outlet of the decondenser 2 is connected to the vapor-liquid separator and liquid storage 3, and the vapor-liquid separator and liquid storage 3 The gas outlet of the evaporative condenser is directly connected to the evaporative condenser 4, the liquid outlet is connected to the evaporative condenser 4 through the throttling element 5, the gas outlet of the evaporative condenser 4 is connected to the suction port of the compressor 1, and the liquid outlet is passed through The liquid receiver 6 and the throttling element 7 are connected to the evaporator 9, and the outlet of the evaporator 9 is connected to the steam suction port of the compressor 1. The refrigerants used are R12 and R23, and R134a and R23 can also be used without a fixed ratio. , the charging amount can meet the normal working needs of the evaporative condenser and the evaporator respectively, and...

Embodiment 2

[0022] The refrigerant uses R22 and R23.

[0023] Others are the same as in Embodiment 1, except that a condensing pressure regulating valve 10 is connected between the partial condenser 2 and the vapor-liquid separator and liquid reservoir 3, and a back pressure valve or the like can be used.

[0024] When R22 and R23 are used as the mixed working fluid, after the components are condensed and separated, due to the influence of mutual solubility, when the suction pressure of the compressor reaches atmospheric pressure, the evaporation temperature of the high-temperature components in the evaporative condenser reaches -50°C below, while the low-temperature components are only about -70°C. Due to the low evaporation temperature of the high-temperature component (R22) in the evaporative condenser, the condensation pressure of the low-temperature component is very low, which will reduce the exhaust pressure of the compressor, causing the high-temperature part (R22) in the deconden...

Embodiment 3

[0027] Other as embodiment 1 or embodiment 2, just be connected with relief valve 11 between gas-liquid separator and accumulator 3 and compressor 1, relief valve 11 can be electromagnetic valve, and electromagnetic valve is connected with compressor pressure sensor, relay control. When the compressor starts to start, the exhaust pressure will be between 2.0 and 3.0Mpa, and the opening pressure of the pressure relief valve is set to 1.8Mpa. After the unit is started, the pressure sensor and relay will open the solenoid valve to release the pressure, so that the compressor will discharge. The steam pressure is maintained at 1.8Mpa for a period of time. Since the work of the decondenser is not affected by pressure relief, the high-temperature component refrigerant is normally throttled and evaporated, gradually reducing the temperature and pressure of the evaporative condenser, and soon (about 10 minutes) the exhaust pressure of the compressor is reduced to below 1.8Mpa , the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com