Dehydration apparatus for treating mercury-containing sludge

A dehydration device and sludge technology, applied in grain treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of low sludge dehydration efficiency, polluting the environment, direct removal and inability to carry out subsequent treatment, and achieve Achieve crushing effect, high efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

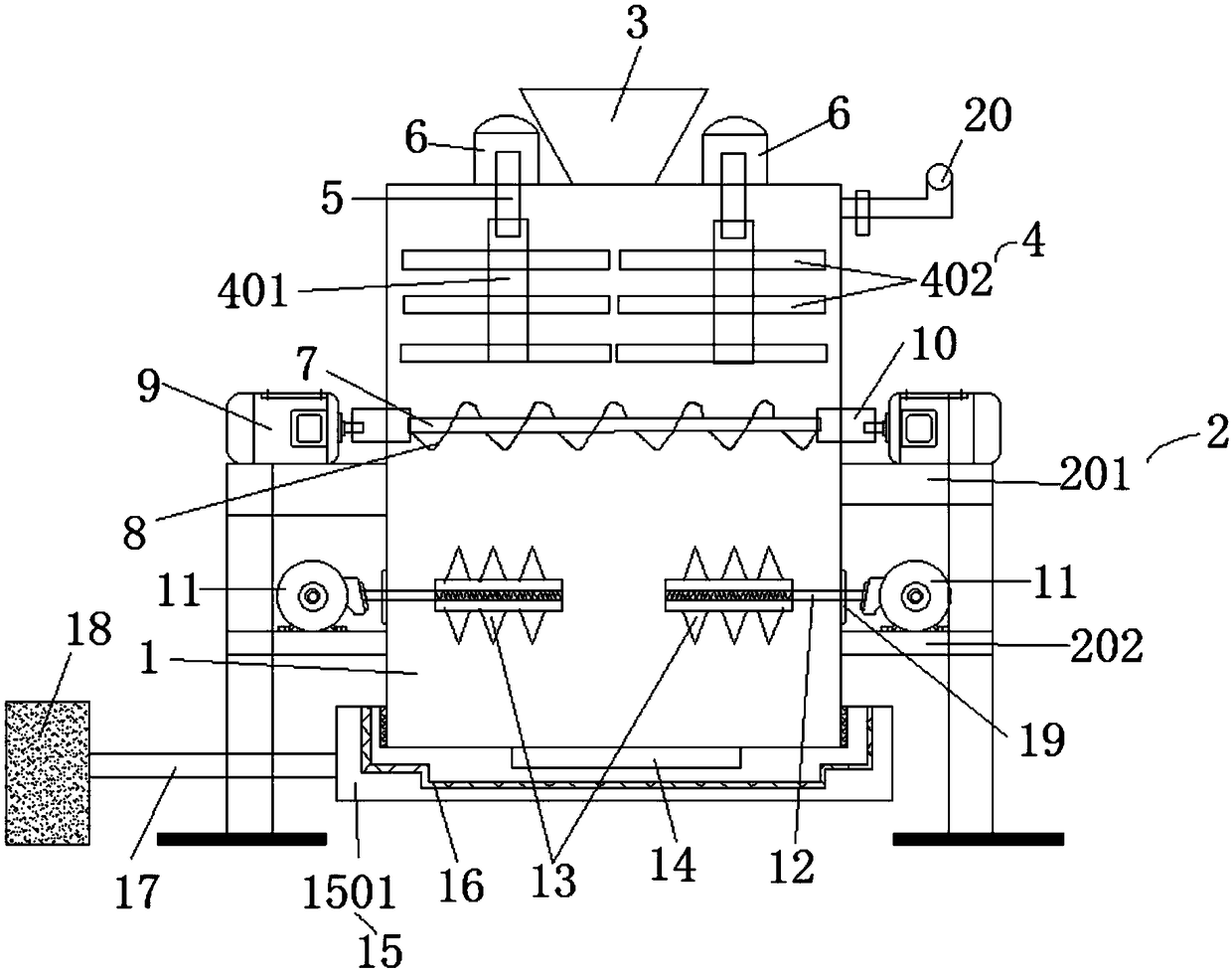

[0016] Embodiment 1: see figure 1 Now, a dehydration device for treating mercury-containing sludge provided by the present invention is described, including a dehydration device body 1, and the dehydration device body 1 is fixed on a frame 2, and the frame 2 is composed of a first layer frame 201 Composed of the second layer of frame 202, the upper end of the dehydration device body 1 is provided with a feed inlet 3, and the two sides of the dehydration device body 1 are provided with a stirring assembly 4, and the stirring assembly 4 includes an agitating shaft 401. The stirring shaft 401 is connected with the stirring motor 6 through the power supply body 5, a plurality of stirring rod bodies 402 are installed on the shaft body of the stirring shaft 401, and an extruding rod 7 is installed on the lower end of the stirring assembly 4, and the extruding rod 7 Extrusion blades 8 are installed on the body of the extruder rod 7, and a rotating motor 9 is installed at both ends of...

Embodiment 2

[0017] Example 2: see figure 1 , as an improvement of the present invention, the rotating motors 9 at both ends of the extruding rod 7 are synchronous rotating motors.

Embodiment 3

[0018] Embodiment 3: see figure 1 , as an improvement of the present invention, an annular sealing ring 19 is provided on the outside of the crushing shaft 12 and the dehydrator body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com