Antirust composite calcium sulfonate-based lubricating grease and preparation method thereof

A composite calcium sulfonate-based lubricating grease and technology of composite calcium sulfonate, applied in lubricating compositions, petroleum industry, etc., can solve the problems of mediocre performance, little industrialization, late research, etc., and achieve reasonable formula and anti-rust performance Outstanding, low raw material cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

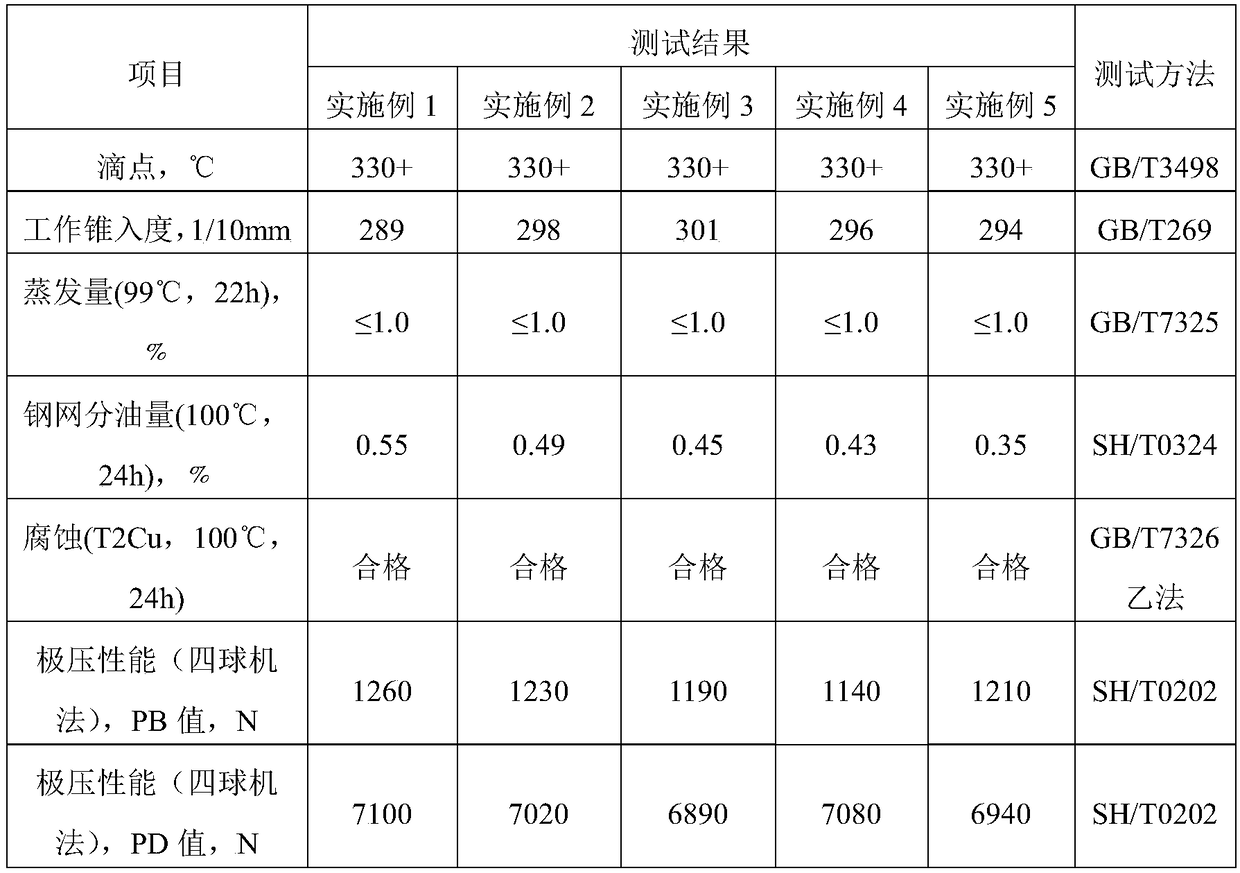

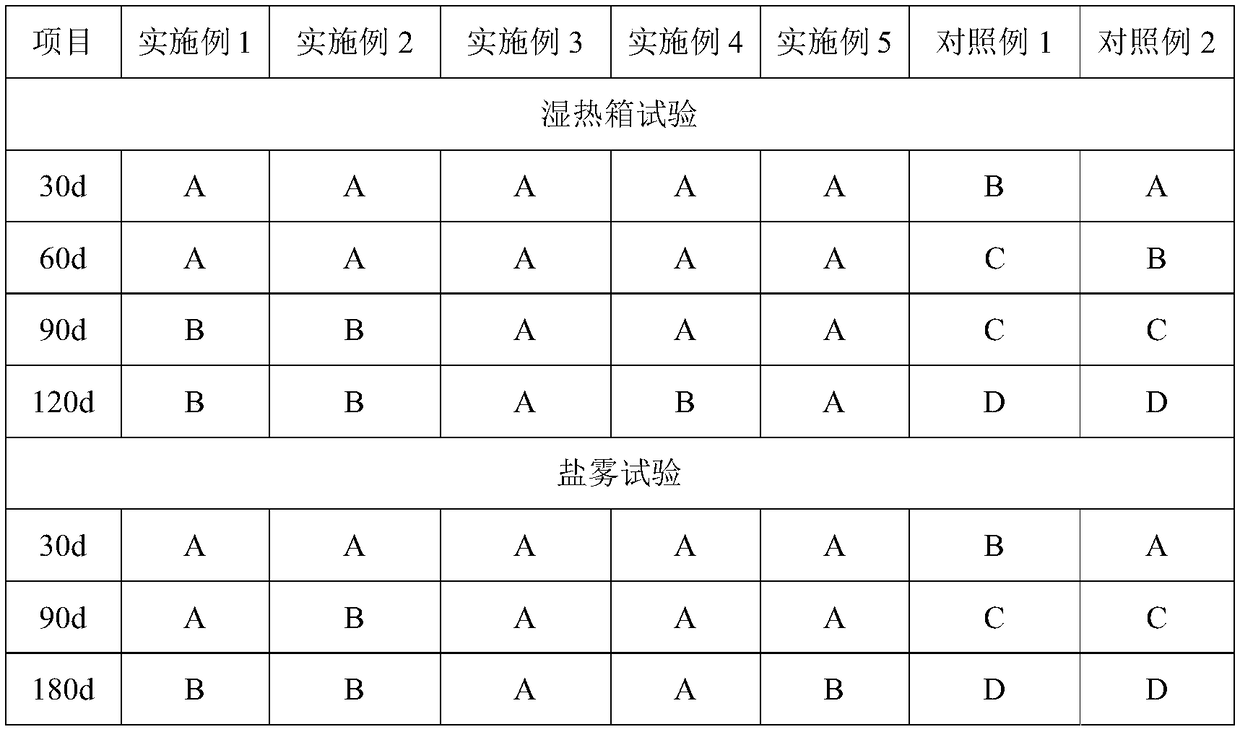

Examples

Embodiment 1

[0025] Party:

[0026] 50 parts of high alkali value calcium sulfonate, 20 parts of polyalkylcyclopentane, 5 parts of alkylbenzenesulfonic acid, 0.5 part of calcium carbonate, 2 parts of organic thickener, 0.5 part of 2-mercaptobenzothiazole, benzimidazole 1 serving.

[0027] The total base number of the high base value calcium sulfonate is 350mgKOH / g.

[0028] The organic thickener is sodium polyacrylate.

[0029] Preparation:

[0030] (1) Take high alkali value calcium sulfonate, half of the amount of polyalkylcyclopentane, half of the amount of alkylbenzenesulfonic acid, calcium carbonate, and water as solvents, add them to the reaction kettle and heat to 75 ° C, and stir for 30 minutes;

[0031] (2) Take the remaining amount of polyalkylcyclopentane and alkylbenzenesulfonic acid, add it to the reaction kettle, heat up to 85°C, and heat and stir for 30min;

[0032] (3) Add 2-mercaptobenzothiazole and benzimidazole, and continue to stir for 30 minutes;

[0033] (4) Add ...

Embodiment 2

[0036] Party:

[0037] 50 parts of high alkali value calcium sulfonate, 40 parts of polyalkylcyclopentane, 15 parts of alkylbenzenesulfonic acid, 1.5 parts of calcium carbonate, 6 parts of organic thickener, 1.5 parts of 2-mercaptobenzothiazole, benzimidazole 3 copies.

[0038] The total base number of the high base value calcium sulfonate is 450mgKOH / g.

[0039] The organic thickener is polytetrafluoroethylene.

[0040] Preparation:

[0041] (1) Take high alkali value calcium sulfonate, half of the amount of polyalkylcyclopentane, half of the amount of alkylbenzenesulfonic acid, calcium carbonate, and water as solvents, add them to the reaction kettle and heat to 85°C, and stir for 60 minutes;

[0042] (2) Take the remaining amount of polyalkylcyclopentane and alkylbenzenesulfonic acid, add it to the reaction kettle, heat up to 95°C, and heat and stir for 60min;

[0043] (3) Add 2-mercaptobenzothiazole and benzimidazole, and continue to stir for 60 minutes;

[0044] (4) ...

Embodiment 3

[0047] Party:

[0048] 50 parts of high alkali value calcium sulfonate, 30 parts of polyalkylcyclopentane, 10 parts of alkylbenzenesulfonic acid, 1 part of calcium carbonate, 4 parts of organic thickener, 1 part of 2-mercaptobenzothiazole, benzimidazole 2 servings.

[0049] The total base number of the high base value calcium sulfonate is 400mgKOH / g.

[0050] The organic thickener is polyacrylamide.

[0051] Preparation:

[0052] (1) Take high alkali value calcium sulfonate, half of the amount of polyalkylcyclopentane, half of the amount of alkylbenzenesulfonic acid, calcium carbonate, and water as solvents, add them to the reaction kettle and heat to 80°C, and stir for 45 minutes;

[0053] (2) Take the remaining amount of polyalkylcyclopentane and alkylbenzenesulfonic acid, add it to the reaction kettle, heat up to 90°C, and heat and stir for 45min;

[0054] (3) Add 2-mercaptobenzothiazole and benzimidazole, and continue to stir for 45min;

[0055] (4) Add an organic thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com