Adjustable axial-torsion coupling vibration suppression device for drill string

A technology of coupling vibration and suppression devices, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of poor torsional vibration suppression effect, difficulty in ensuring strength, and high cost, so as to ensure energy consumption, improve production efficiency, and improve Effect of Vibration Suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

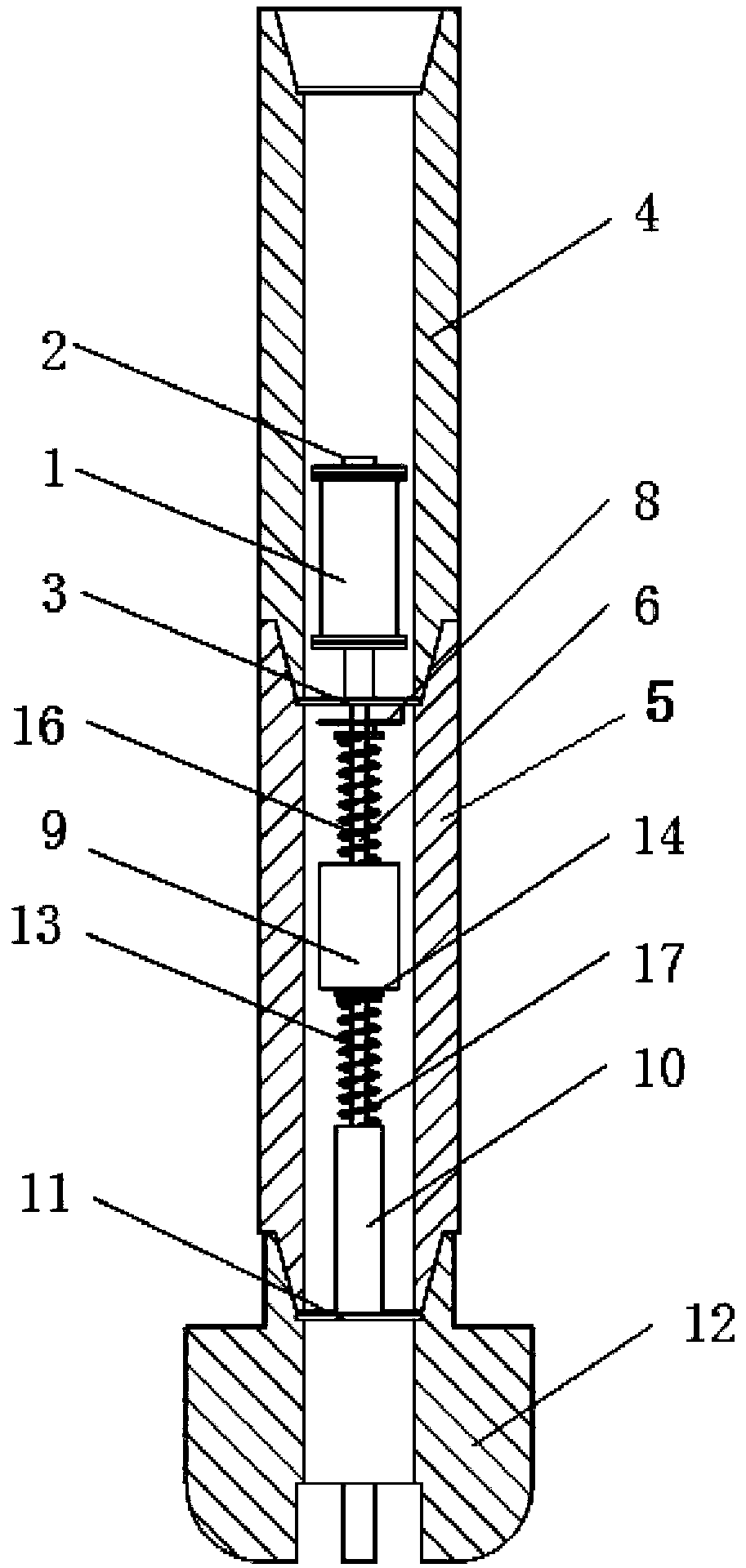

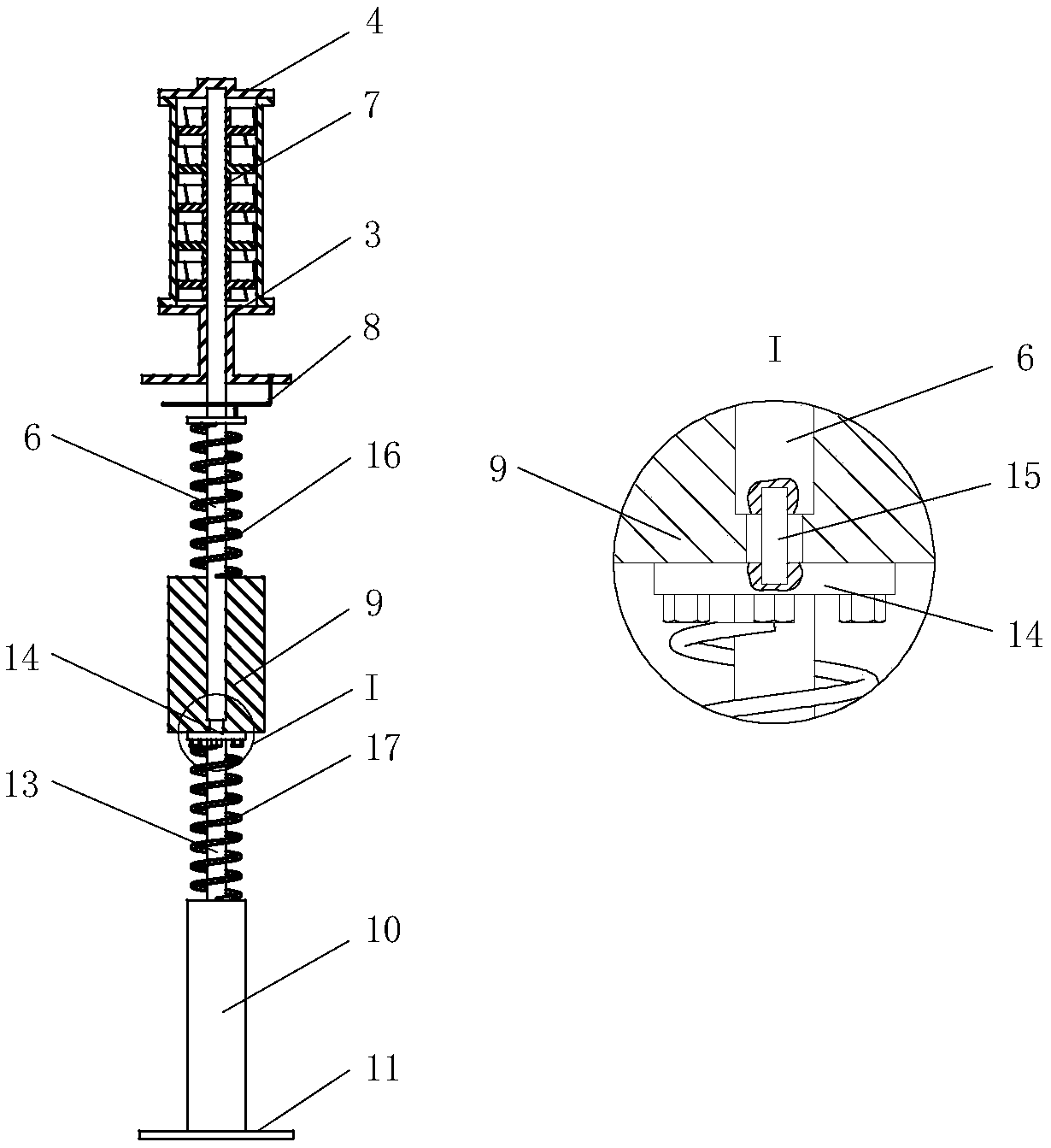

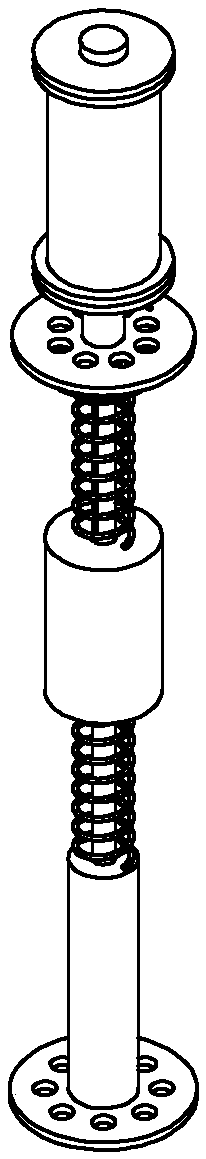

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0040] As shown in the figure, the present invention provides an adjustable drill string axial-torsional coupling vibration suppression device, and the technical scheme is as follows:

[0041] The rotary damping cylinder 1 is a cylindrical hollow structure, the upper part of the rotary damping cylinder 1 is connected with the shaft sealing cover 2; the lower part of the rotary damping cylinder 1 is connected with the through-flow transparent cover 3; The connection between the drill collar 4 and the lower drill collar 5; a rotating shaft 6 is installed in the middle of the rotating damping cylinder 1, and a rotating blade 7 is installed on the upper part of the rotating shaft 6; a rotating elastic element 8 is installed above the middle part of the rotating shaft 6, so that T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com