Rotary cylinder device

A rotary and cylinder technology, applied in multi-cylinder pumps, variable capacity engines, liquid variable capacity machines, etc., can solve the problems of low energy conversion efficiency, reduce energy loss, simplify structure, and improve energy conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

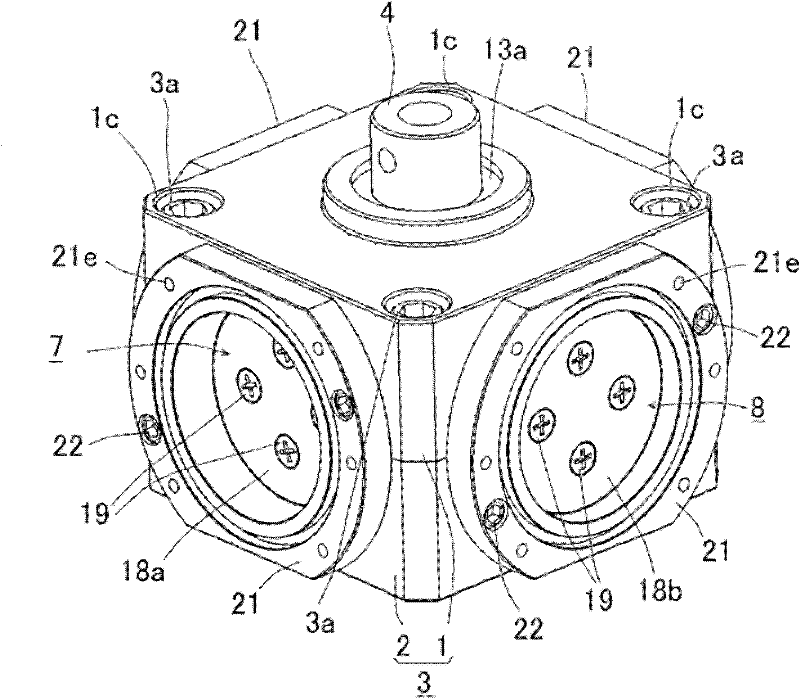

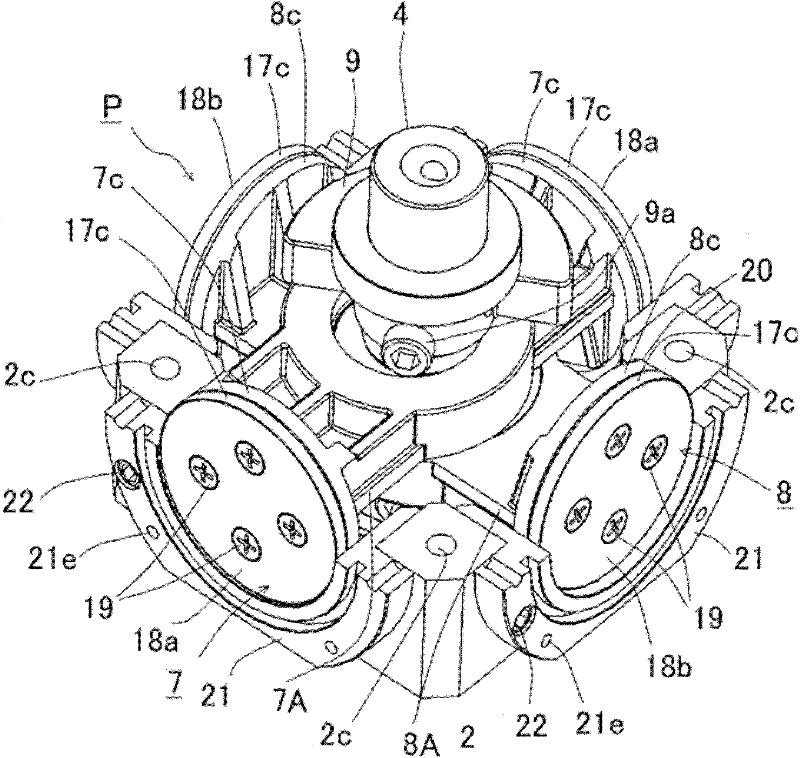

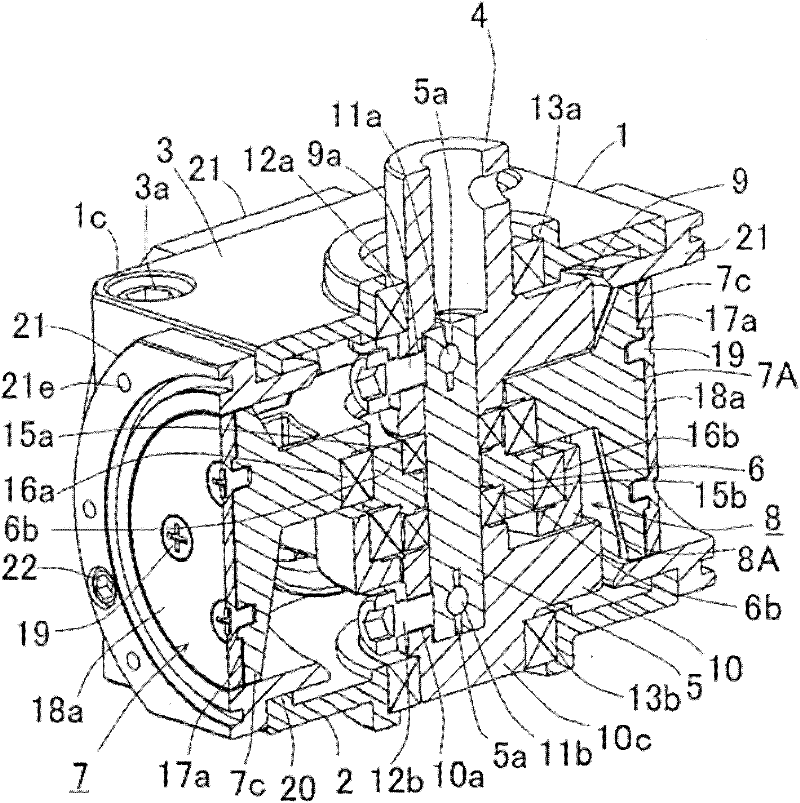

[0069] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. will refer to Figures 1 to 23B A rotary cylinder device to be incorporated in a compressor will be described as an embodiment of the present invention. The rotary cylinder device can convert the reciprocating motion of the piston in the cylinder and the rotary motion of the shaft to each other.

[0070] exist figure 1 Among them, a shaft (input / output shaft) 4 is rotatably held in a main body case 3 composed of a first case 1 and a second case 2 . The first housing 1 and the second housing 2 are integrated by bolts 3 a respectively provided at four corners of the main body housing 3 . Such as image 3 As shown, in the main body housing 3, the eccentric cylindrical body 6 that can rotate around the first crankshaft 5 and constitutes the composite piston assembly P (see figure 2 ) and the first piston unit 7 and the second piston unit 8, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com