Filling apparatus

A technology of filling device and filling port, which is applied in the direction of power device, container filling method, container structure installation device, etc. It can solve the problem of detachment of filling nozzle 30, achieve the effect of reducing sealing structure and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

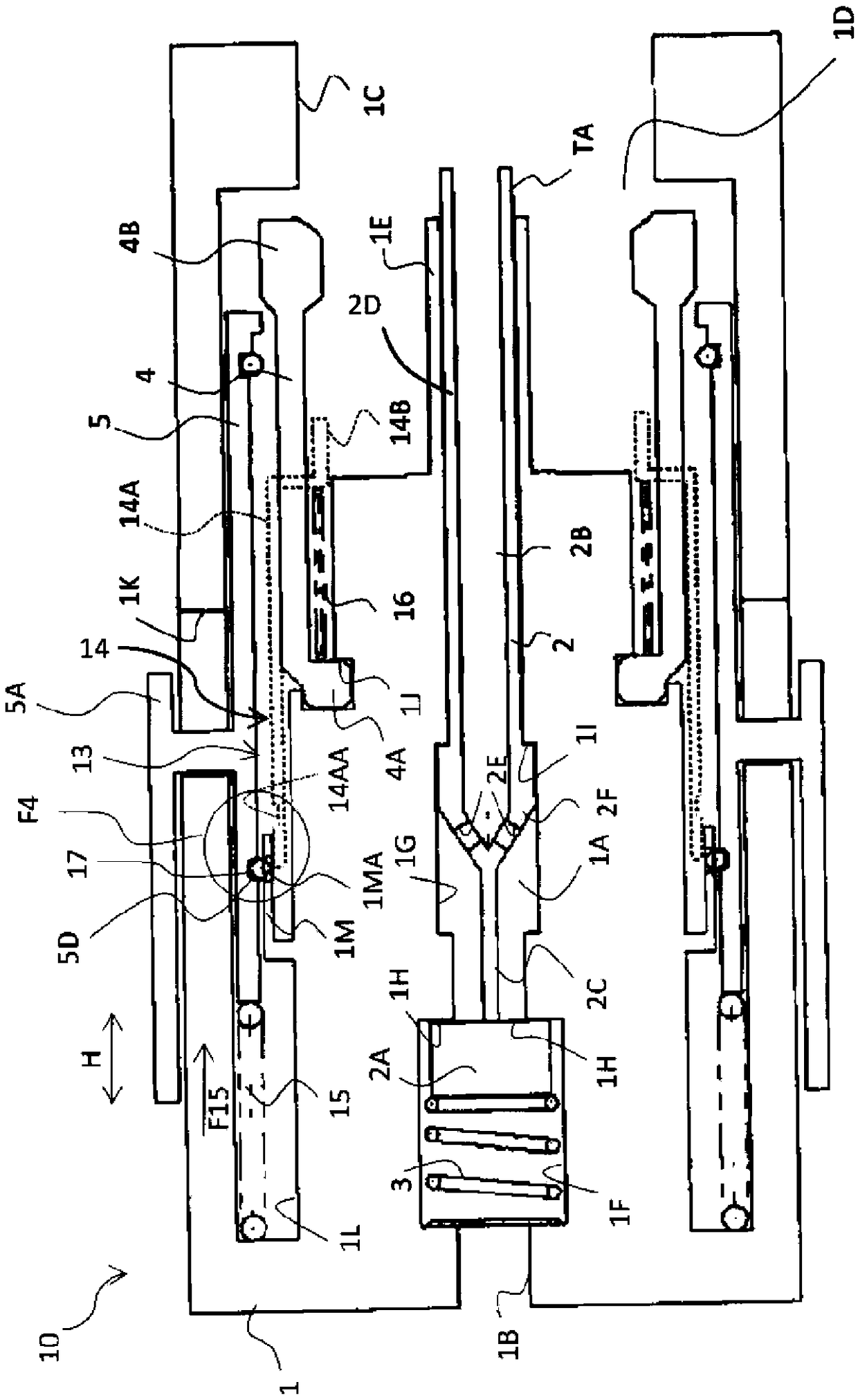

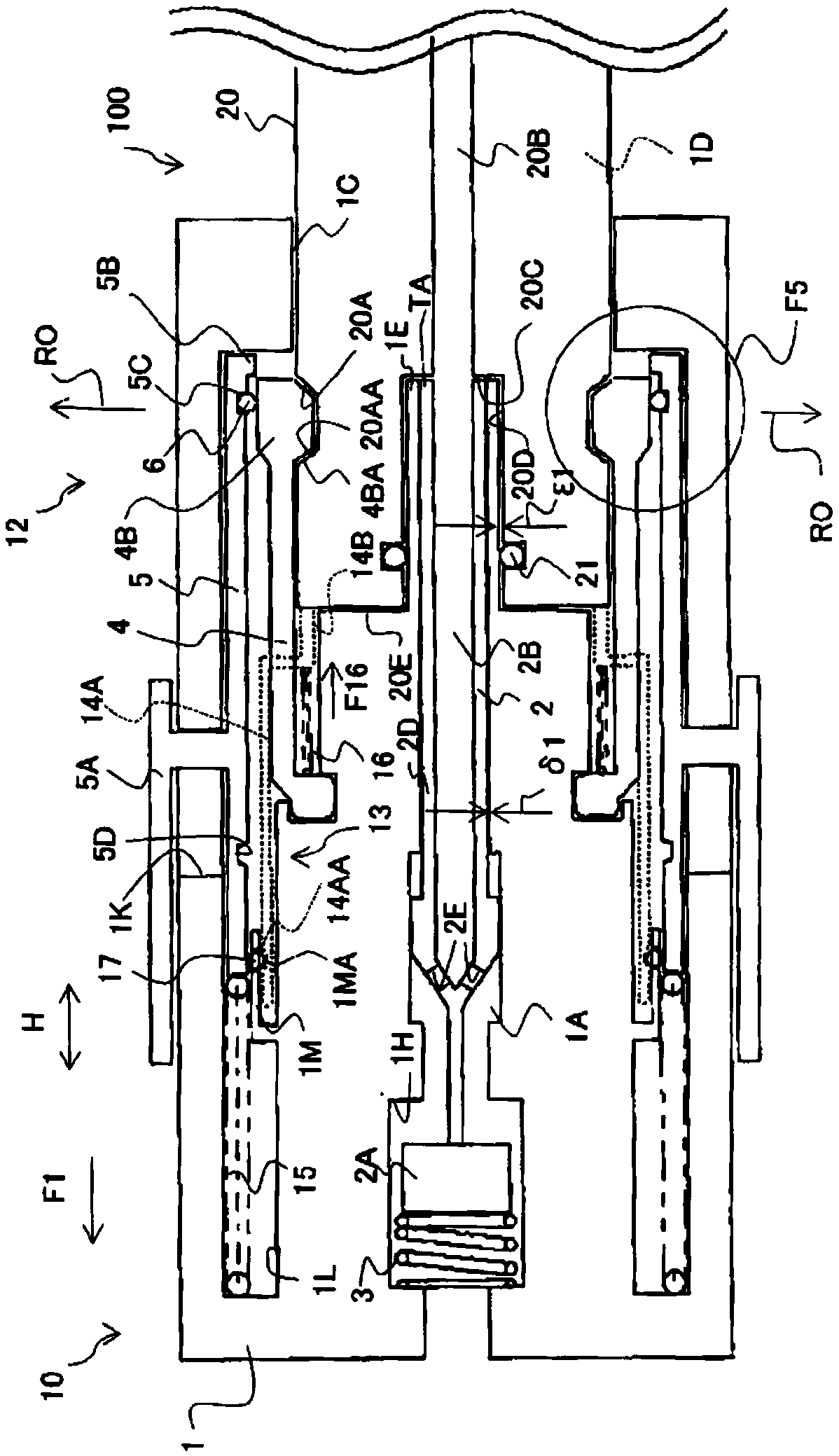

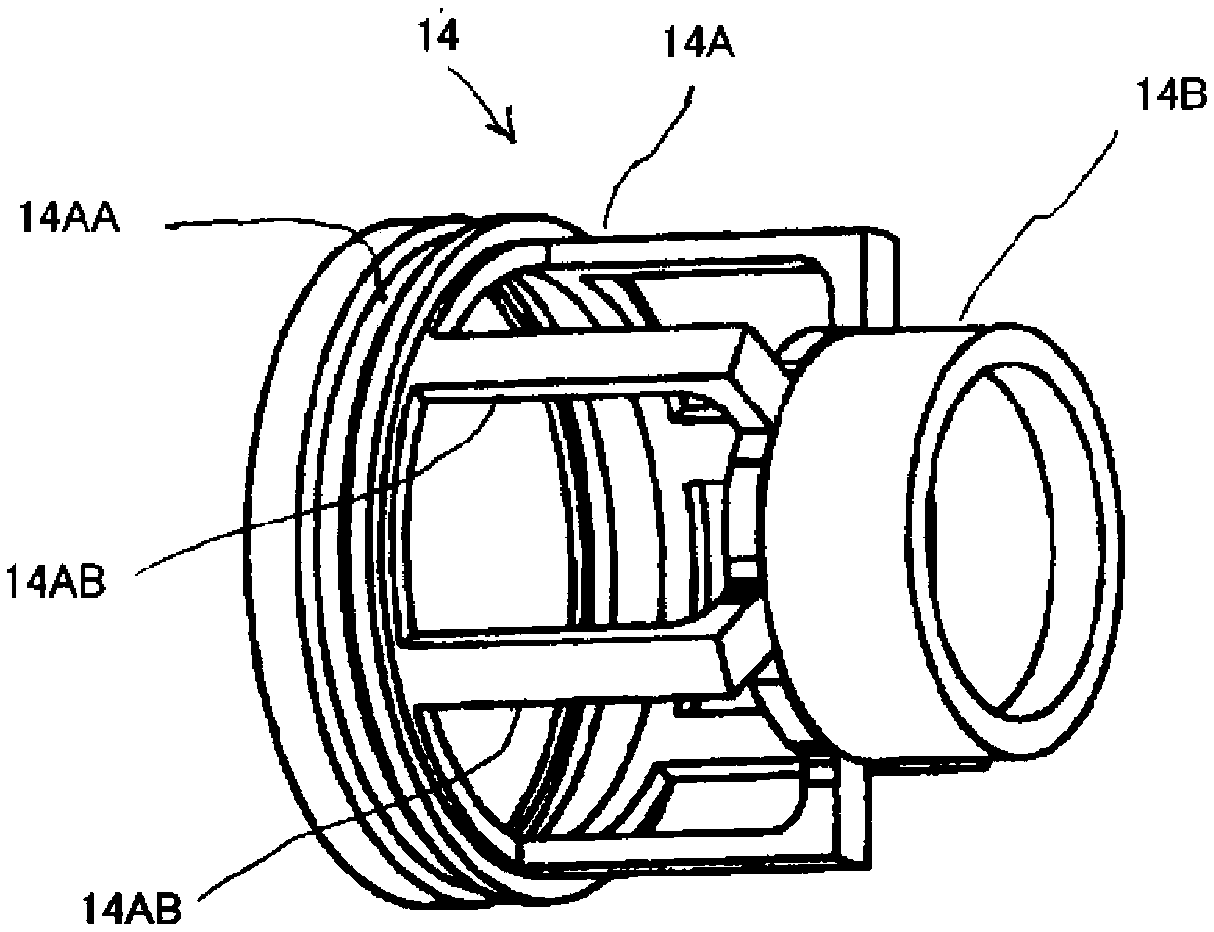

[0058] Below, refer to Figure 1 to Figure 5 Embodiments of the present invention will be described. figure 1 Filling nozzle 10 shown from Image 6 The shown hydrogen fuel storage container 50 fills the vehicle-mounted hydrogen filling container 41 with hydrogen via a fuel filling system (dispenser 60 , filling hose 45 , etc.). The filling nozzle 10 has a pipe joint main body 1 on the hydrogen supply source side of the pipe joint main body 1 (in figure 1 Middle is the left side) the central part of the end (in the figure 1 The center part in the vertical direction) is provided with a hydrogen introduction port 1B connected to the filling hose side (not shown). And, on the side of the socket of the pipe joint main body 1 (the side of the filling port on the vehicle side, on the figure 1 The middle is the right side) end is provided with for jack 20 ( figure 2 ) into opening 1C. On the hydrogen supply source side of the opening 1C in the pipe joint 1 (in figure 1 In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com