An automatic guidance method for the measurement of miniature circular holes

An automatic guidance and round hole technology, applied in the field of image processing, can solve problems such as difficult to complete guidance operations, low measurement efficiency, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

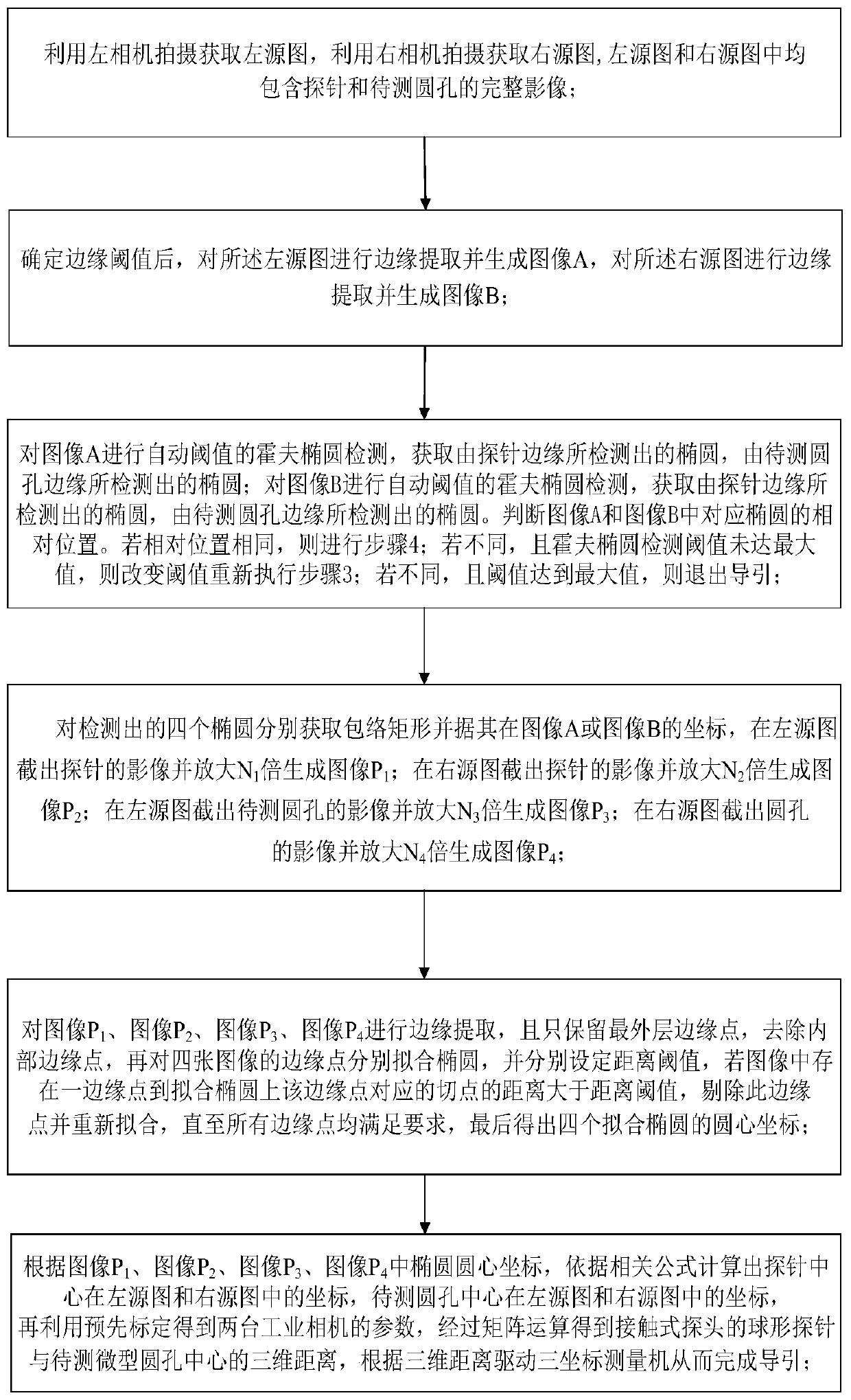

Method used

Image

Examples

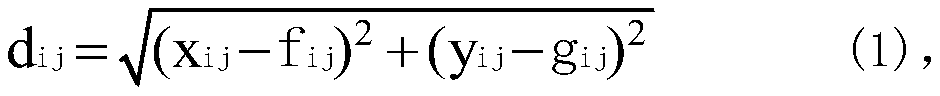

Embodiment Construction

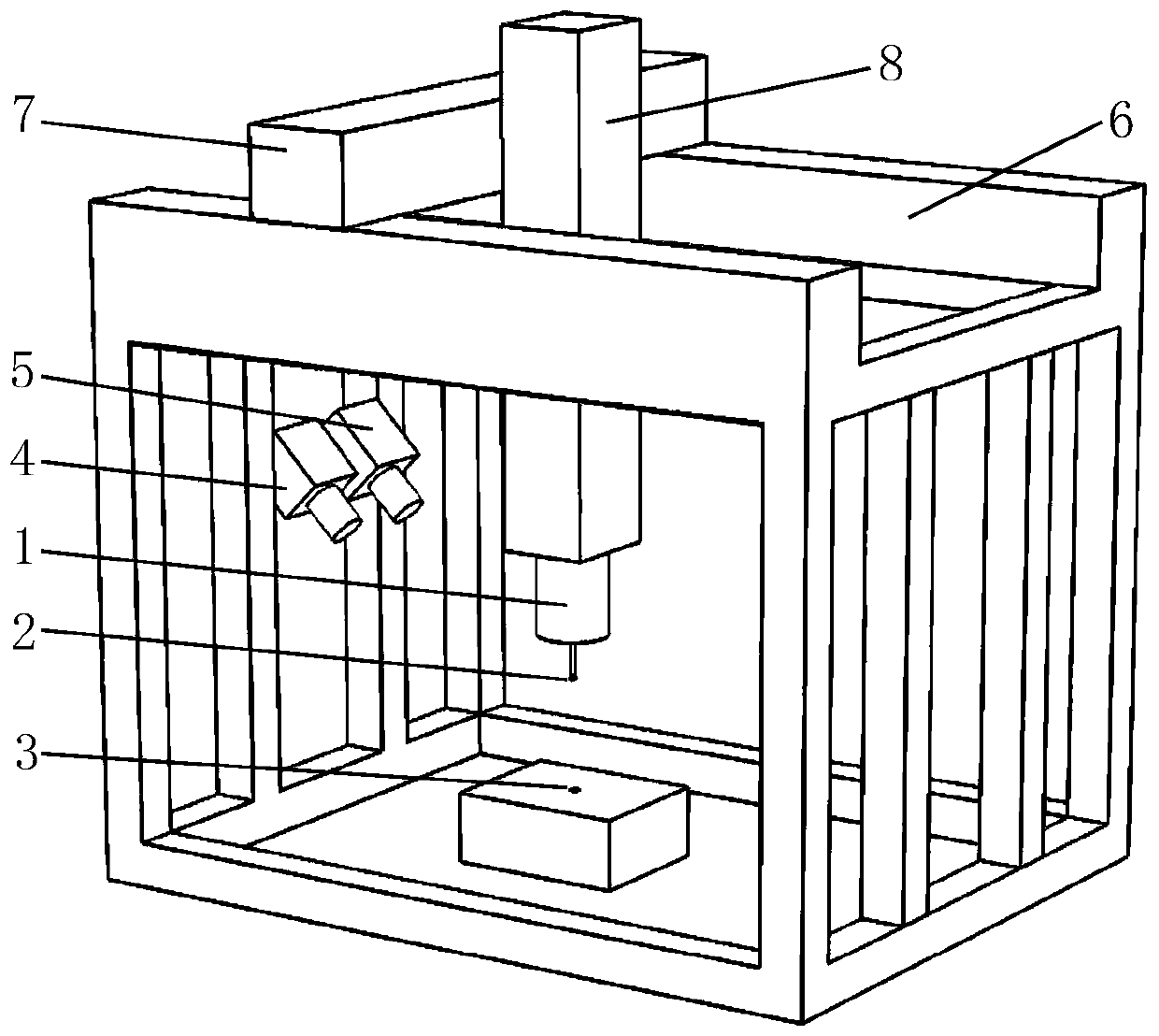

[0040] see figure 2 , in the present embodiment, the measurement of the miniature circular hole refers to adopting a three-coordinate measuring machine, and utilizing the probe 2 at the front end of the contact-type measuring probe to probe into the circular hole 3 to be measured for micro-hole measurement; the three-coordinate measuring machine consists of a base, X Axis 6, Y-axis 7 and Z-axis 8 are fixed on the base of one side of the three-coordinate measuring machine. Left camera 4 and right camera 5 with the same model and parallel optical axes are fixed. On the Z-axis 8 of the measuring machine, a spherical probe 2 is installed on the top of the contact measuring probe 1, and the probe 2 and the round hole 3 to be measured are both in the field of view of the left camera 4 and the right camera 5, where the camera The captured images are all in units of pixels, and the coordinate system is established with the vertex in the upper left corner of the image as the origin. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com