An Intelligent Scheduling Method Based on Flow Control

A flow control and intelligent scheduling technology, applied in logistics, data processing applications, forecasting, etc., can solve the problems of increased congestion risk, unequal AGV busyness, and unequal busyness, so as to avoid path conflicts and road resources competition, reduced congestion and collision probability, and equal opportunity for path use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

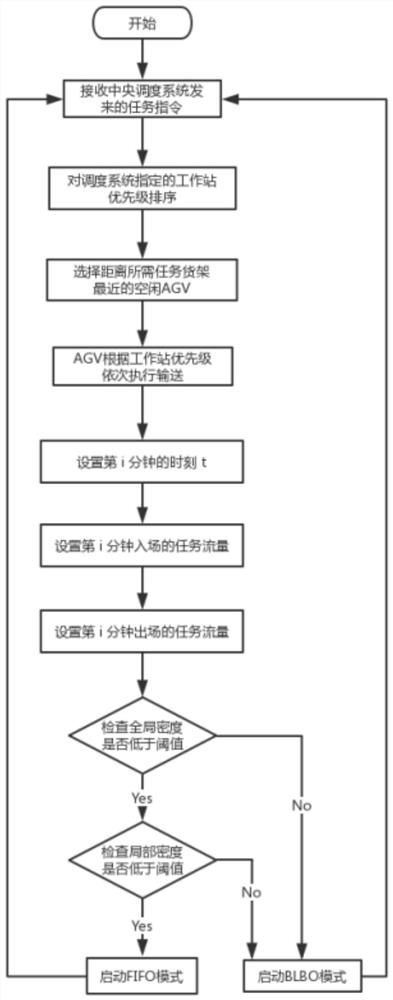

[0047] The object of the present invention is to provide a kind of intelligent scheduling method based on flow control, the specific steps of this intelligent scheduling algorithm based on flow control are as follows:

[0048] S1: Initialization

[0049] 1.1 Receive task instructions from the central dispatching system;

[0050] 1.2 Prioritize the workstations specified by the scheduling system, the calculation method is as follows:

[0051] 1.2.1 The workstation with the least amount of tasks is the first priority;

[0052] 1.2.2 When multiple workstations are in the same order, the smallest workstation ID number is the first priority;

[0053] 1.3 Select the idle AGV closest to the required task shelf;

[0054] 1.4 The AGV completes the transportation in sequence according to the priority of the workstation;

[0055] 1.5 Set the global density threshold;

[0056] 1.6 Set the local density threshold;

[0057] 1.7 Definition of physical parameters and variables:

[0058...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com