A water-cooled head buckle structure

A water-cooled head and buckle technology, applied to instruments, electrical digital data processing, electrical components, etc., can solve problems such as high R&D costs, inability to uniformly control risks, and inability to achieve mass production, and achieve the effect of saving R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

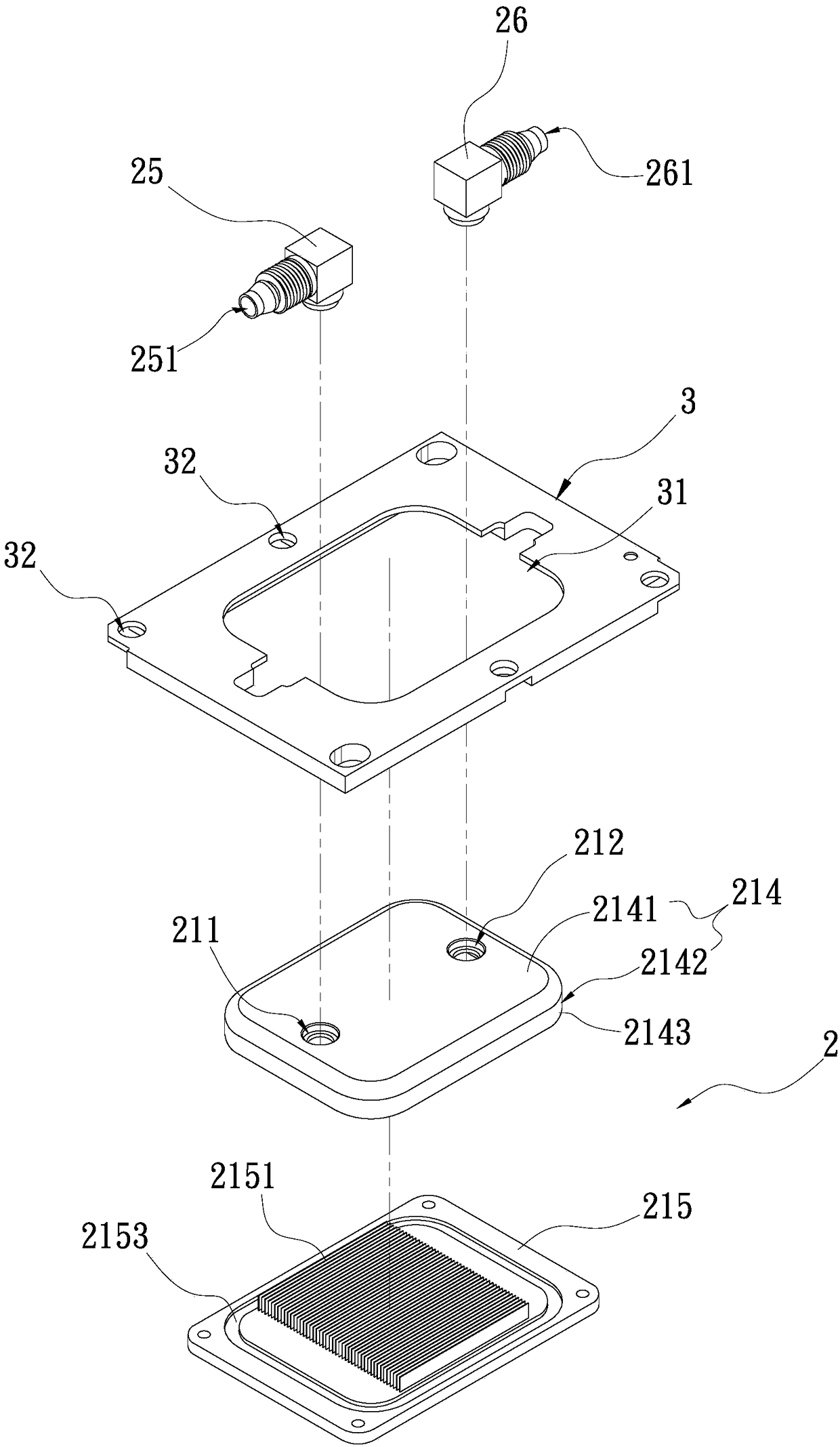

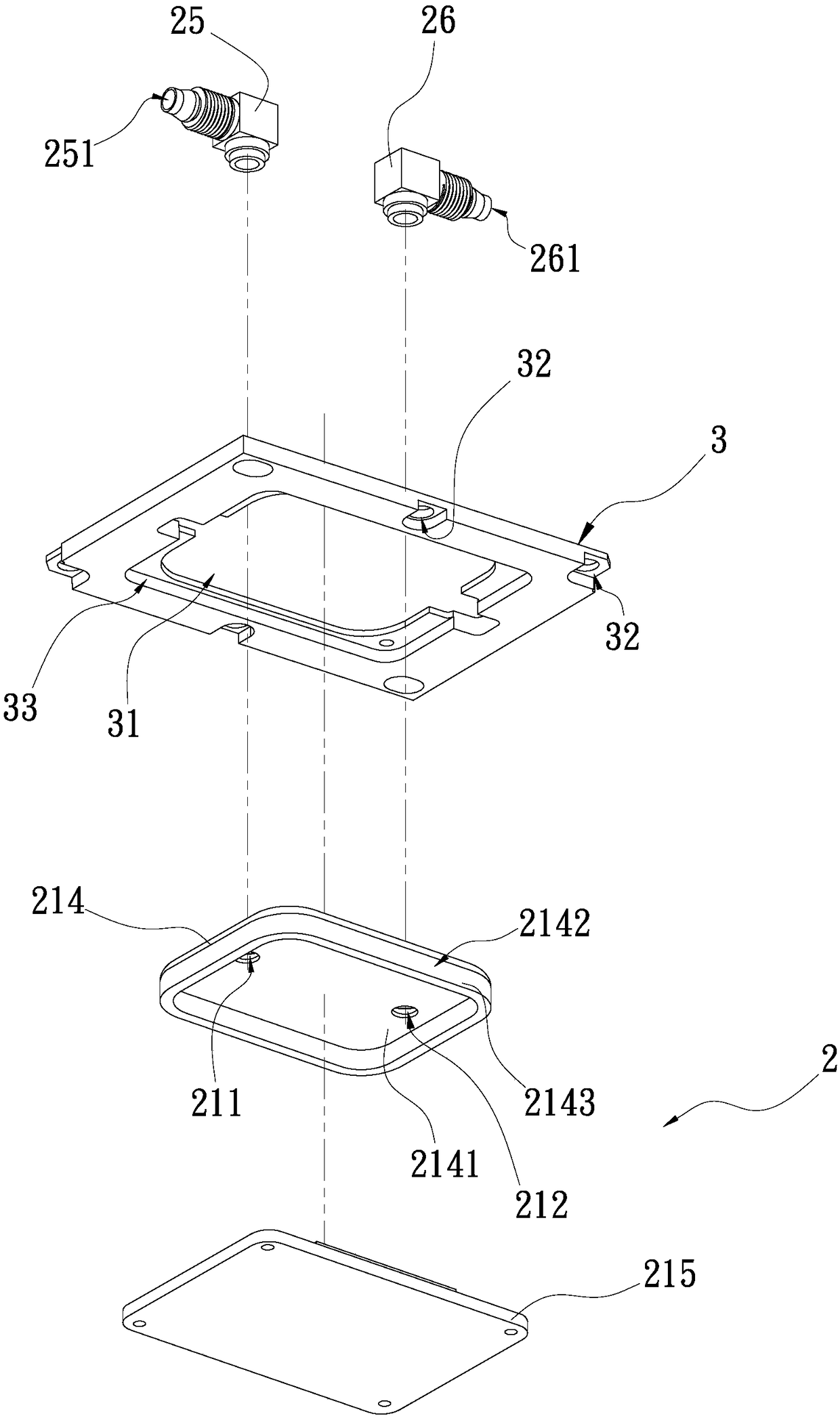

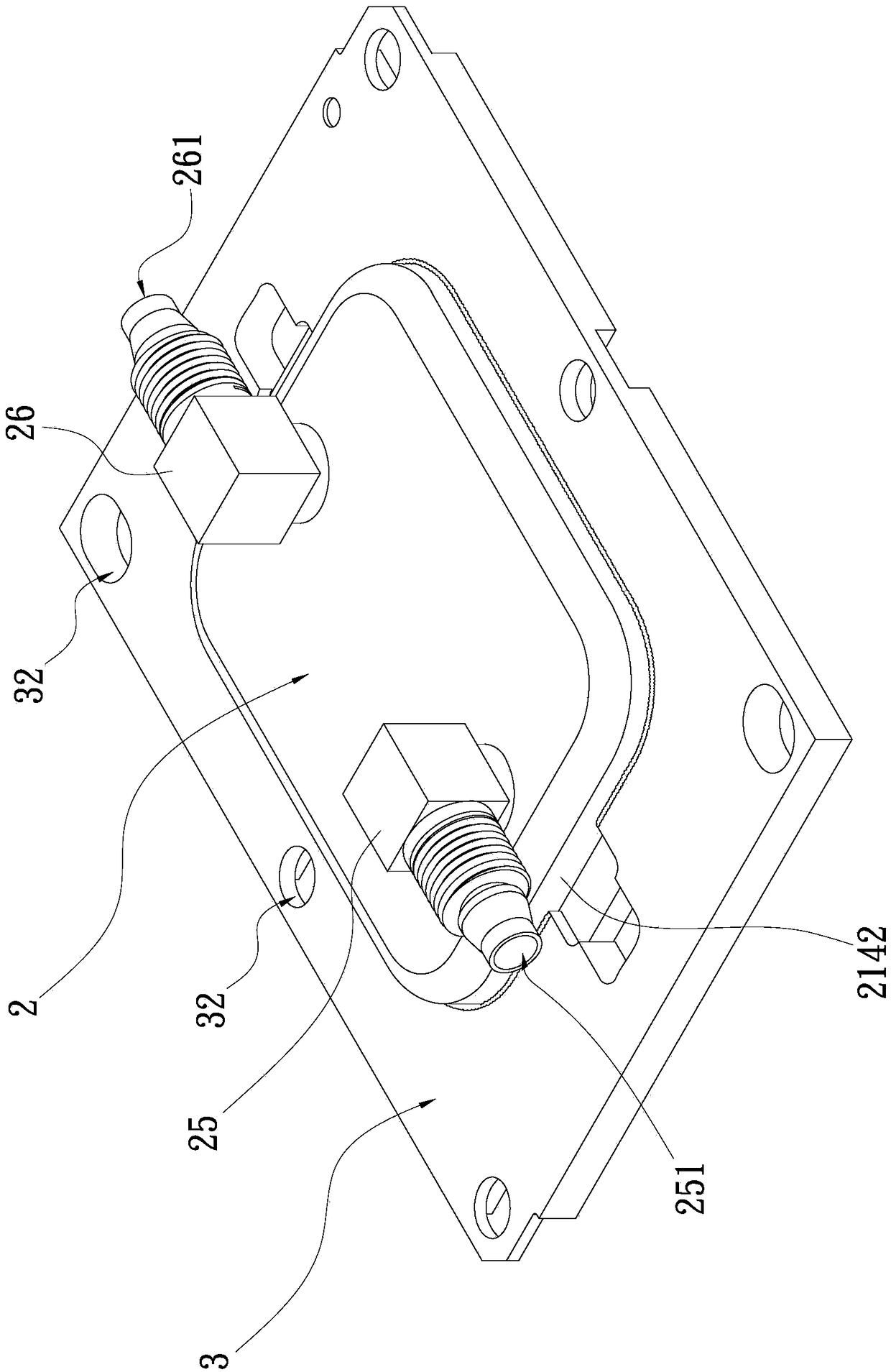

[0042] The present invention is a water-cooled head buckle structure, please refer to Figure 1A It is a three-dimensional exploded schematic view of the first embodiment of the present invention; Figure 1B It is a perspective exploded schematic diagram of another viewing angle of the first embodiment of the present invention; Figure 2A It is a three-dimensional combination schematic diagram of the first embodiment of the present invention; Figure 2B It is a three-dimensional combined partial cross-sectional schematic diagram of the first embodiment of the present invention; Figure 3A It is an exploded schematic diagram of the implementation form of the first embodiment of the present invention; Figure 3B It is a combined schematic diagram of the implementation style of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com