A preparation method of a magnesium sulfur battery electrolyte containing lithium ion additive and an application thereof

A magnesium-sulfur battery and additive technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problem that magnesium-sulfur batteries cannot be charged and discharged at high rates, and achieve good oxidation stability, wide applicability, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step (1): Add 0.04 g lithium powder into 10 ml 0.5 M / L HMDS system magnesium-sulfur battery electrolyte and stir for 24 hours.

[0025] (2) Let the solution of step (1) stand for 48 hours.

[0026] (3) Take the clear liquid part of step (2), which is the HMDS system magnesium-sulfur battery electrolyte containing lithium ion additives.

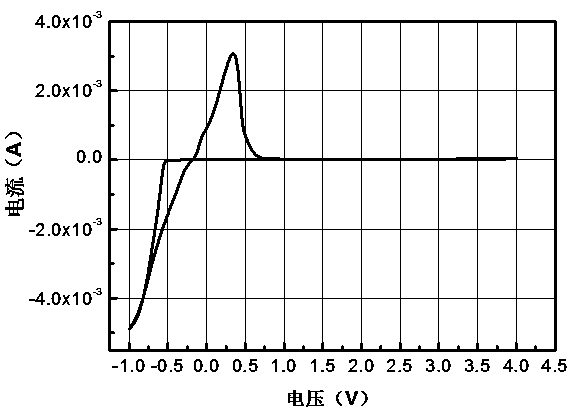

[0027] Depend on figure 1 From the cyclic voltammetry curve shown, it can be seen that the electrolytic solution has good reversibility to the deposition and stripping of magnesium and has no other impurity redox peaks.

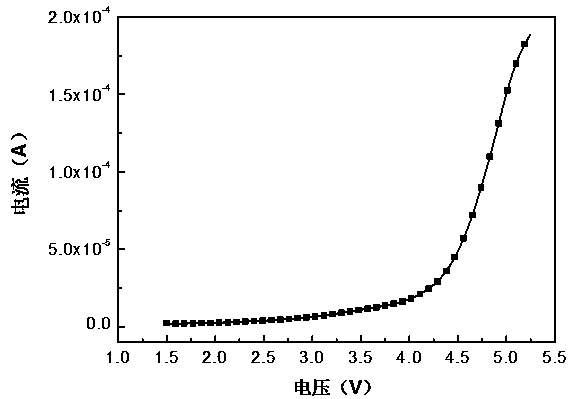

[0028] Depend on figure 2 The shown LSV curve shows that the electrochemical stability window of the electrolyte is higher than 3.5 V.

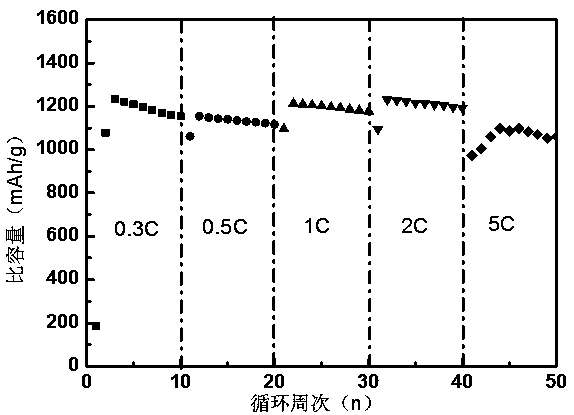

[0029] Depend on image 3 The rate performance curve of the Mg / S full battery shown shows that as the charge-discharge rate increases, the battery discharge capacity decays less, and the discharge specific capacity of 1000 mAh / g can still be maintained at 5 C.

[0030] Depend on...

Embodiment 2

[0033] Step (1): Add 0.035 g of lithium powder into 10 ml of 0.4 M / L MACC system magnesium-sulfur battery electrolyte and stir for 24 hours.

[0034] Step (2): Let the solution of step (1) stand for 48 hours.

[0035] Step (3): Take the clear liquid part of step (2), which is the electrolyte solution for magnesium-sulfur batteries of the MACC system containing lithium ion additives.

Embodiment 3

[0037] Step (1): Add 0.1 g lithium powder to 10 ml 1 M / L Mg(TFSI) 2 System magnesium-sulfur battery electrolyte and stirred for 24 hours.

[0038] Step (2): Let the solution of step (1) stand for 48 hours.

[0039] Step (3) Take the supernatant part of step (2), which is Mg(TFSI) containing lithium ion additives 2 System magnesium sulfur battery electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com