A capacitive coupling device and a filter

A capacitive coupling and air coupling technology, applied in the field of communication, can solve problems such as unfavorable dielectric filter design, and achieve the effects of small deformation, improved performance, and increased square coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

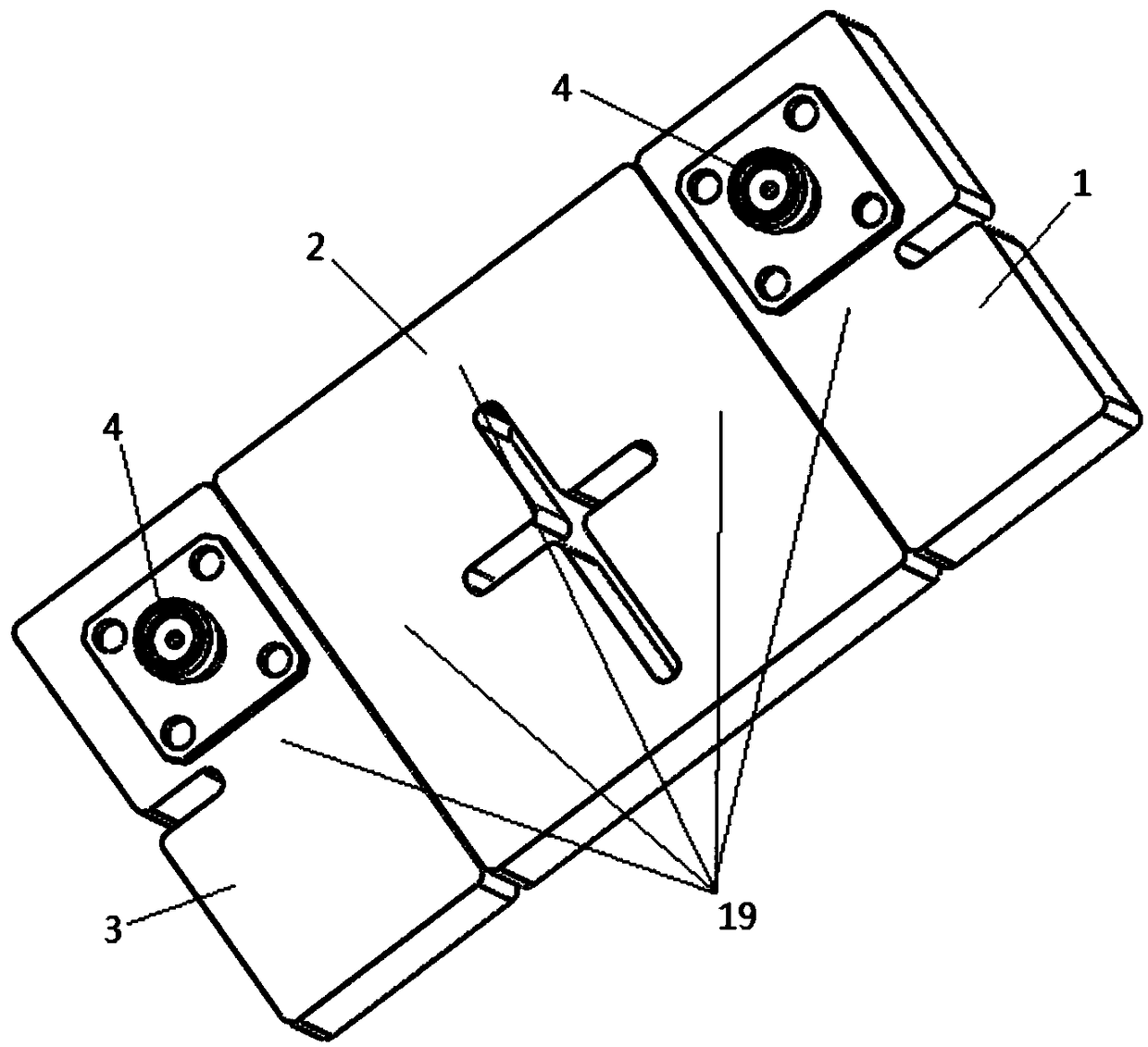

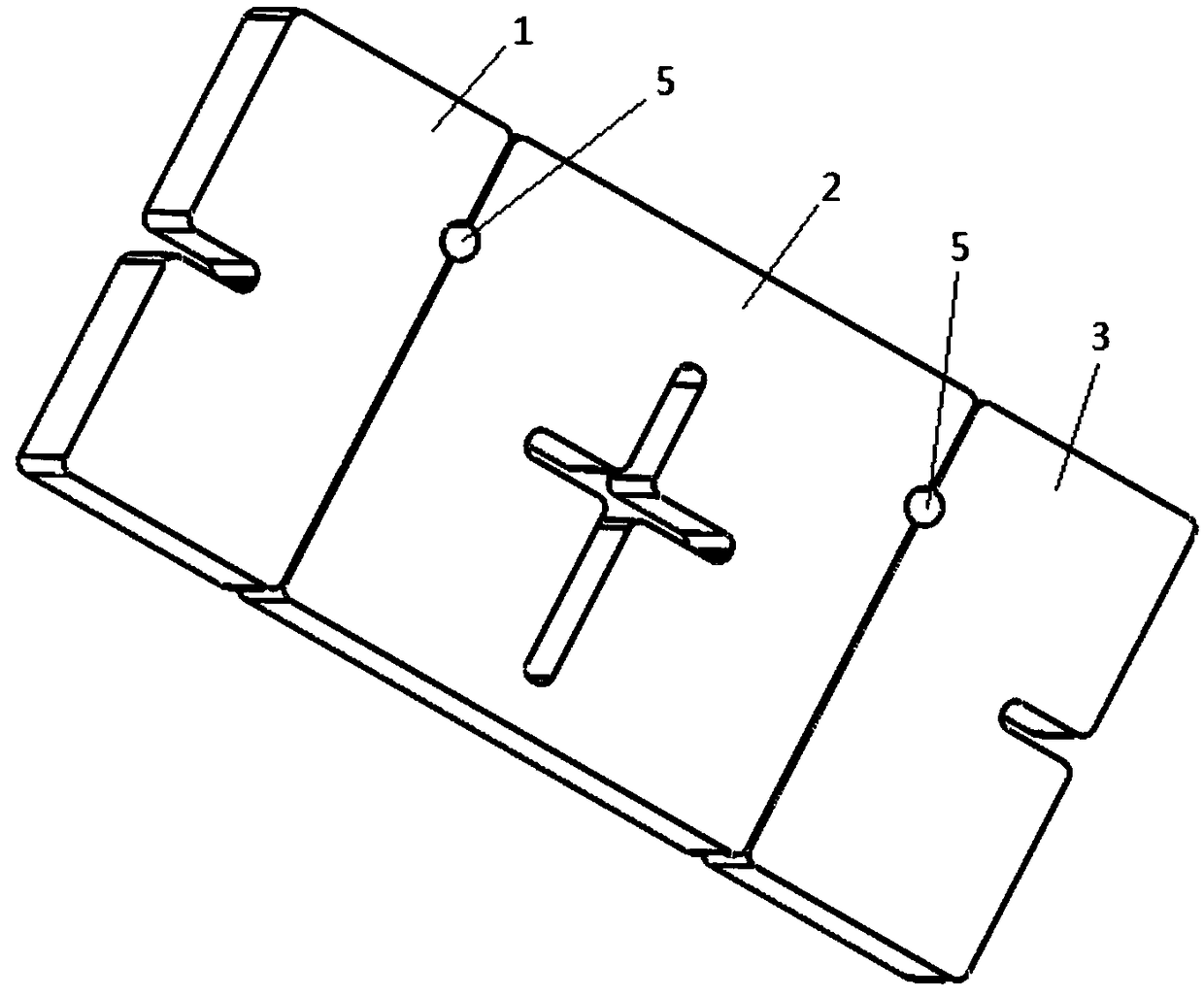

[0045] Such as Figure 1-4As shown, the capacitive coupling device of this embodiment includes three dielectric monomers, namely the first dielectric monomer 1, the second dielectric monomer 2 and the third dielectric monomer 3, and the three dielectric monomers are spliced and connected Form a linear structure, the first dielectric monomer 1 and the third dielectric monomer 3 include two dielectric single cavities, the second dielectric monomer 2 includes four dielectric single cavities, the first dielectric monomer 1 and the second dielectric monomer Between the dielectric single chambers 9 and 10 on 2, and between the dielectric single chambers 13 and 14 on the second dielectric unit 2 and the third dielectric unit 3 are all coupled through the second air coupling window 7 provided on the splicing surface, The medium single cavities 8-15 on the three dielectric monomers form the main coupling channel 16, and the two non-adjacent medium single cavities (such as between the...

Embodiment 2

[0047] Such as Figure 5-8 As shown, the difference between this embodiment and Embodiment 1 is that the arrangement of the three dielectric cells is different. The capacitive coupling device of this embodiment includes three dielectric cells, namely the first dielectric cell 1, the second dielectric cell Dielectric monomer 2 and third dielectric monomer 3, the three dielectric monomers are spliced and connected to form a character-shaped structure, the first dielectric monomer 1 and the third dielectric monomer 3 include two dielectric single chambers, and the second dielectric monomer The cell 2 includes three medium single cavities, between the first medium cell 1 and the medium single cavity on the second medium cell 2, between the medium single cavity on the second medium cell 2 and the third medium cell 3 Both of them are coupled through the second air coupling window 7 provided on the splicing surface, and the dielectric single cavities 8-14 on the three dielectric mo...

Embodiment 3

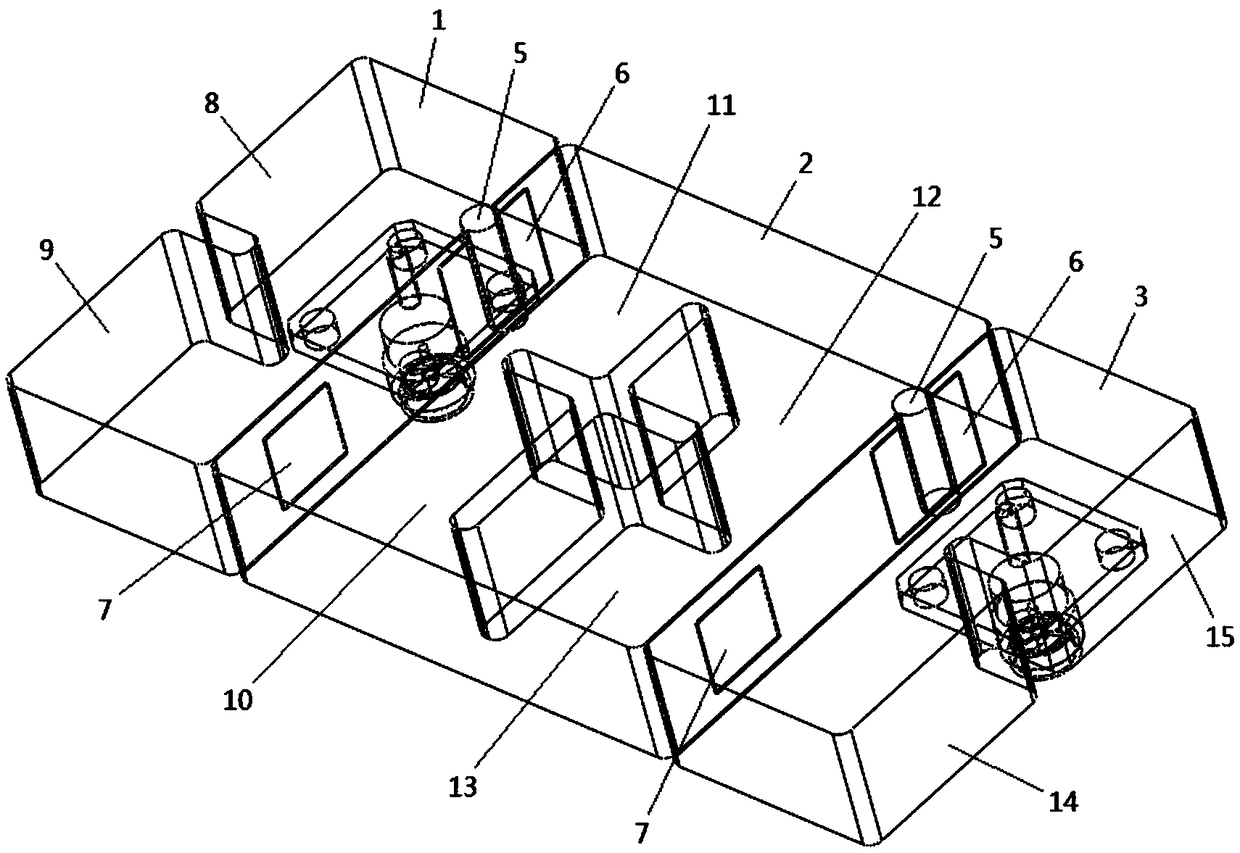

[0049] Such as Figure 9-12 As shown, the capacitive coupling device of this embodiment includes eight dielectric monomers, and the eight dielectric monomers are spliced and connected, wherein four adjacent dielectric monomers form a cross-shaped structure, and the eight dielectric monomers are each Only one dielectric single cavity is included, and the eight dielectric single cavities 8-15 are coupled through the second air coupling window 7 provided on the splicing surface to form the main coupling channel 16. The two non-adjacent dielectric single cavities in the main coupling channel The first blind hole 5 and the first air coupling window 6 provided on the splicing surface form a capacitive coupling between the dielectric single cavities 10 and 13, thereby generating a transmission zero at the low end and high end of the passband. The center of each dielectric single cavity is provided with a second blind hole 17 for frequency tuning, and the inner wall and bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com