Fan brushless motor

A technology of brushless motors and fans, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as easy quality problems and cumbersome assembly procedures, and achieve the effects of simple assembly procedures, stable insulation performance, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in the preferred embodiment are only for convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

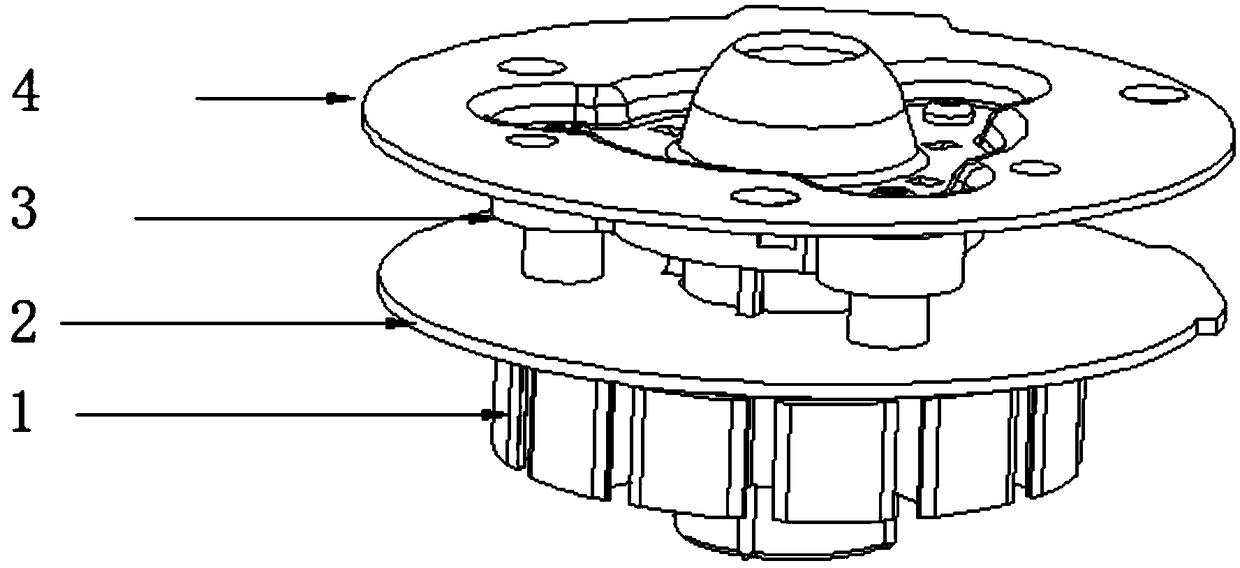

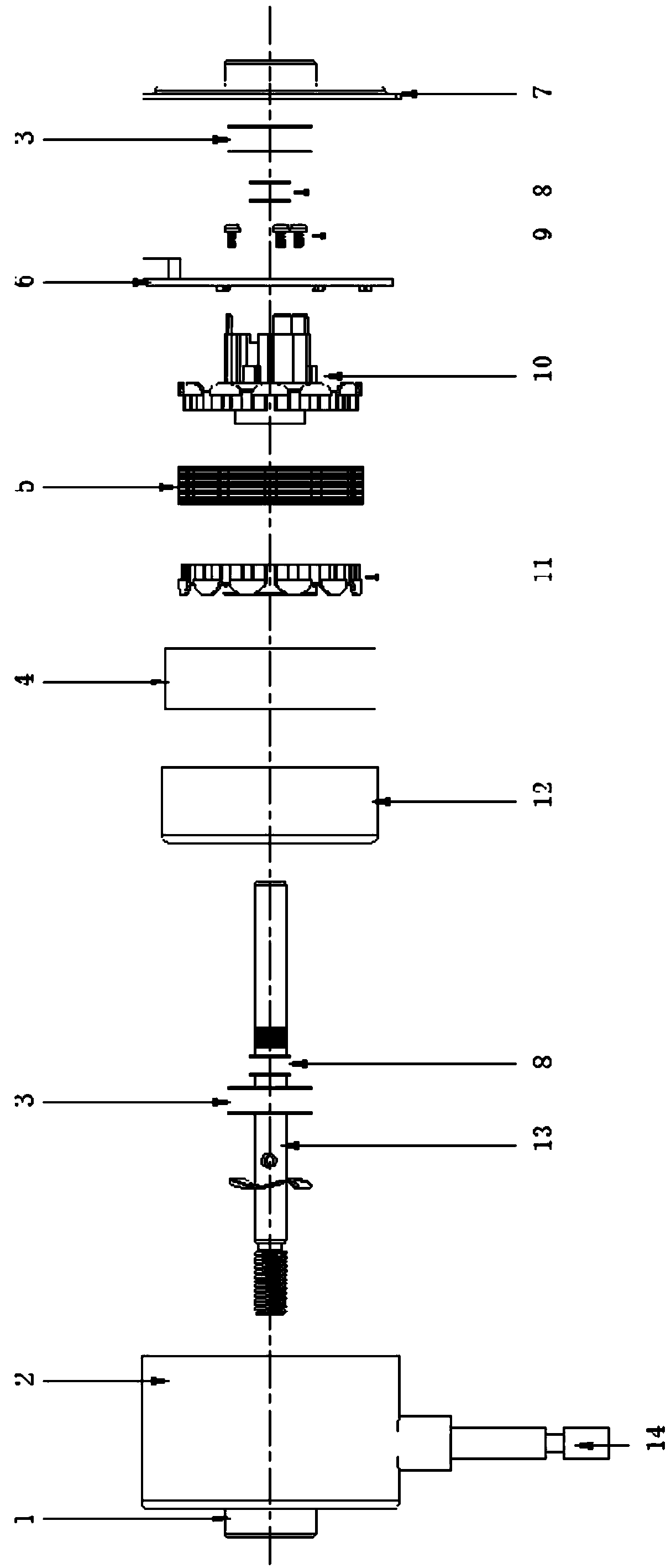

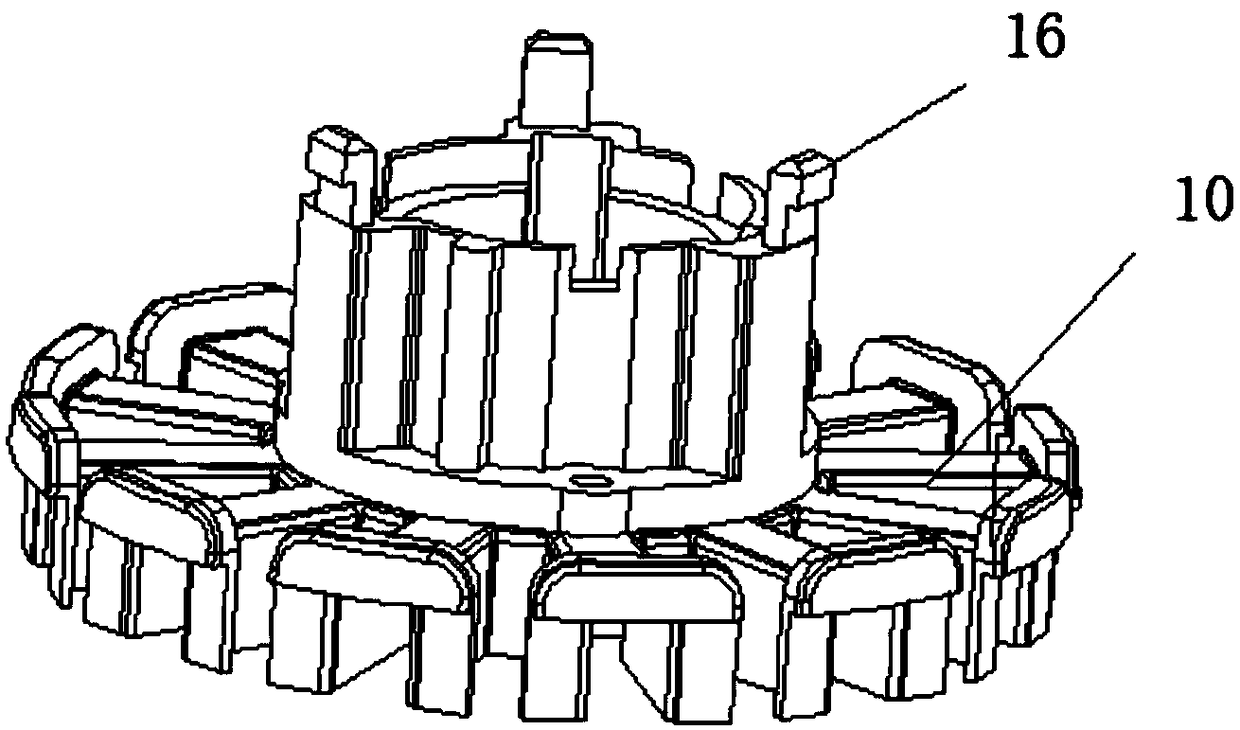

[0036] Such as figure 2 As shown, the fan brushless motor includes a casing 2, a front cover 7 that buckles the opening of the front end of the casing 2, and a stator 5, a rotor and a PCB board arranged in the motor cavity formed by the casing 2 and the front cover 7 6. The rotor includes a rotating shaft 13, a circular cover-shaped magnetic frame 12 sleeved on the rotating shaft 13, and a plastic magnet 4 fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com