System and method for purifying organic contaminated soil by using in-situ thermal desorption of combustion hot air

A technology of organic pollution and thermal desorption, applied in the field of organic polluted soil remediation, can solve the problems of unsuitable organic polluted soil remediation, increase project cost, and high repair cost, so as to increase the residence time of flue gas, reduce energy consumption and increase residence time the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

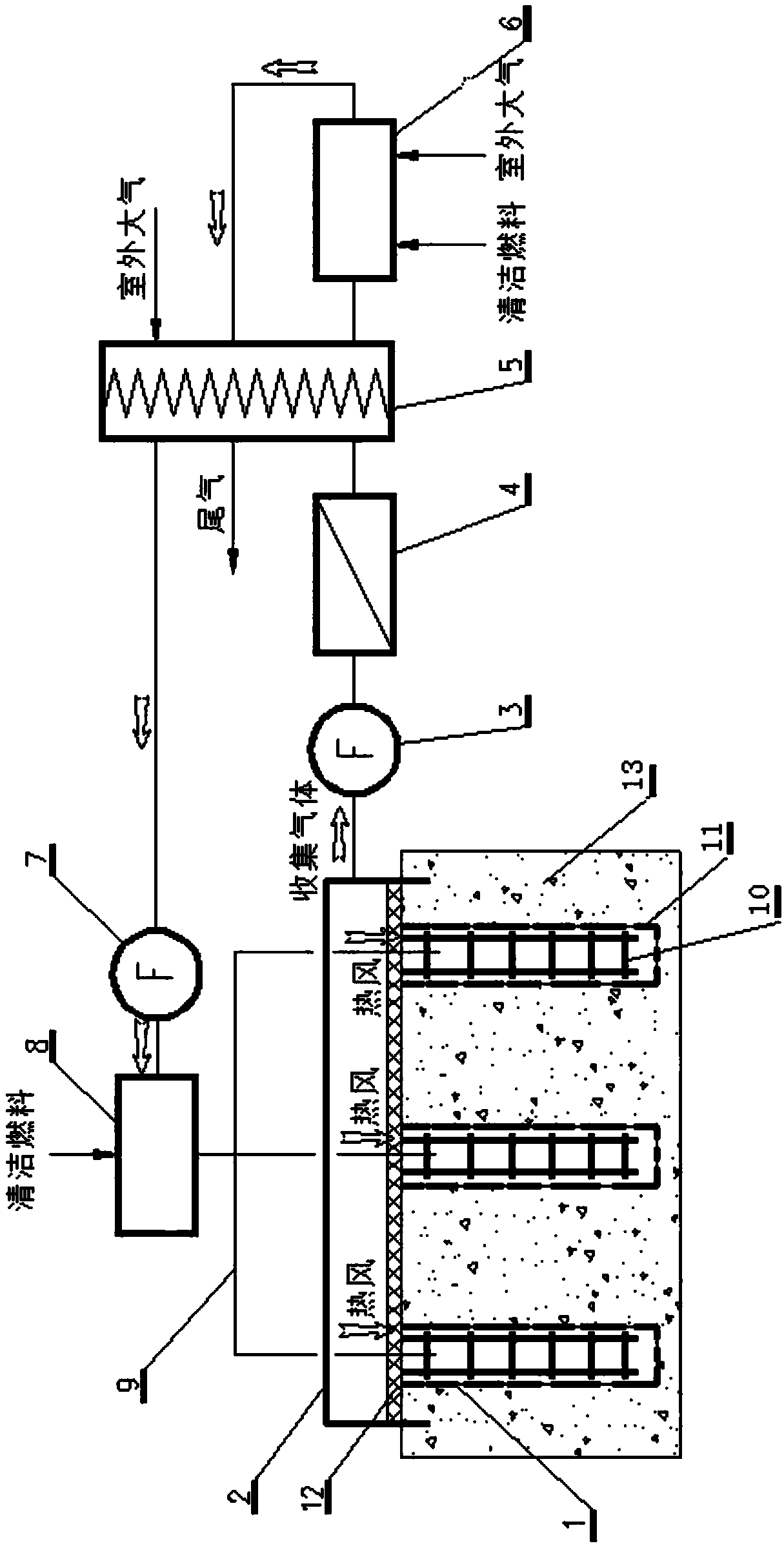

[0034] Such as figure 1 As shown, the system for purifying organically polluted soil by in-situ thermal desorption of hot air from combustion according to the present invention includes a heating unit 1, a collection unit 2, a negative pressure fan 3, a heat exchange unit 5, a combustion purification unit 6, and a positive pressure fan 7 and a circulation purification system composed of a combustion unit 8; the heating unit 1 is a plurality of uniformly inserted in the organic polluted soil, the top of the heating unit 1 is flush with the surface of the organic polluted soil 13 and a screen 12 is arranged on it , the top of the heating unit 1 is provided with a collection unit 2, the collection unit 2 is a cover structure, and the bottom end of its side is inserted into the organic polluted soil 13 and surrounds the heating unit 1; the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com