One-step forming construction method of shaft bridge through cast-in-situ concrete floor

A construction method and concrete technology, which are applied in the direction of floor slab, formwork/formwork/work frame, and on-site preparation of building components, etc., can solve the problem that the gap between the shaft bridge and the concrete wall is small, which affects the visual quality of concrete buildings, and the lower floor Shaft and bridge pollution and other problems, to achieve the effect of low construction environment requirements, saving labor costs, and reducing construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

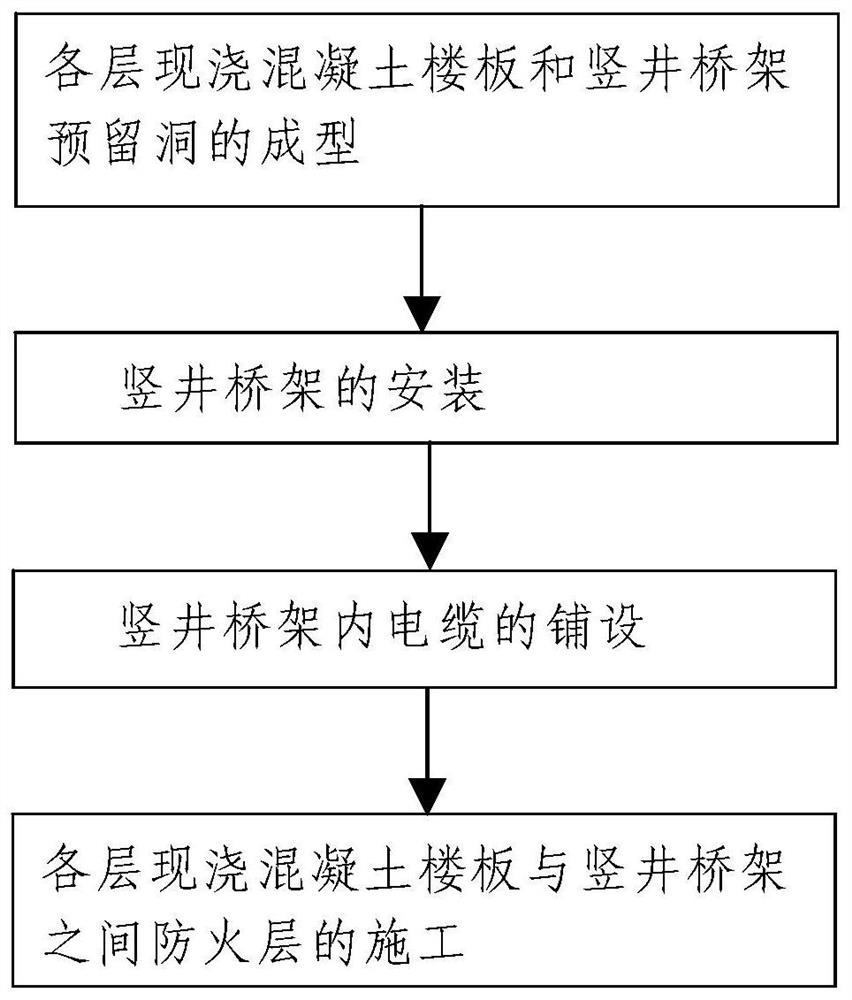

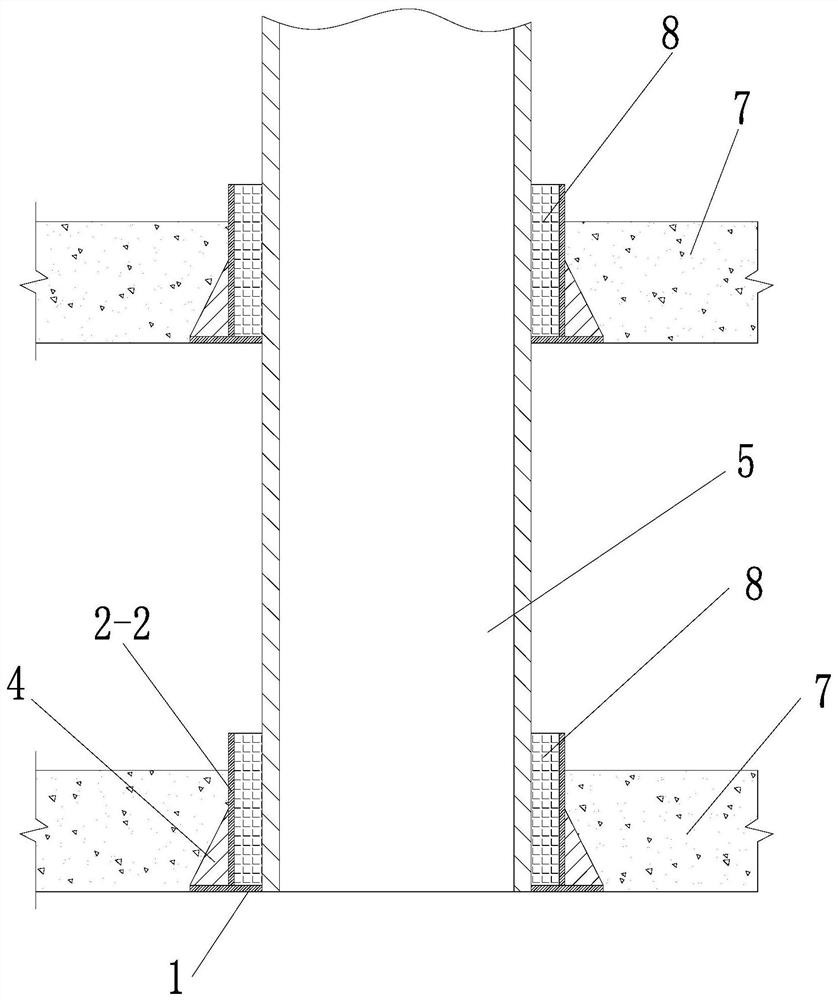

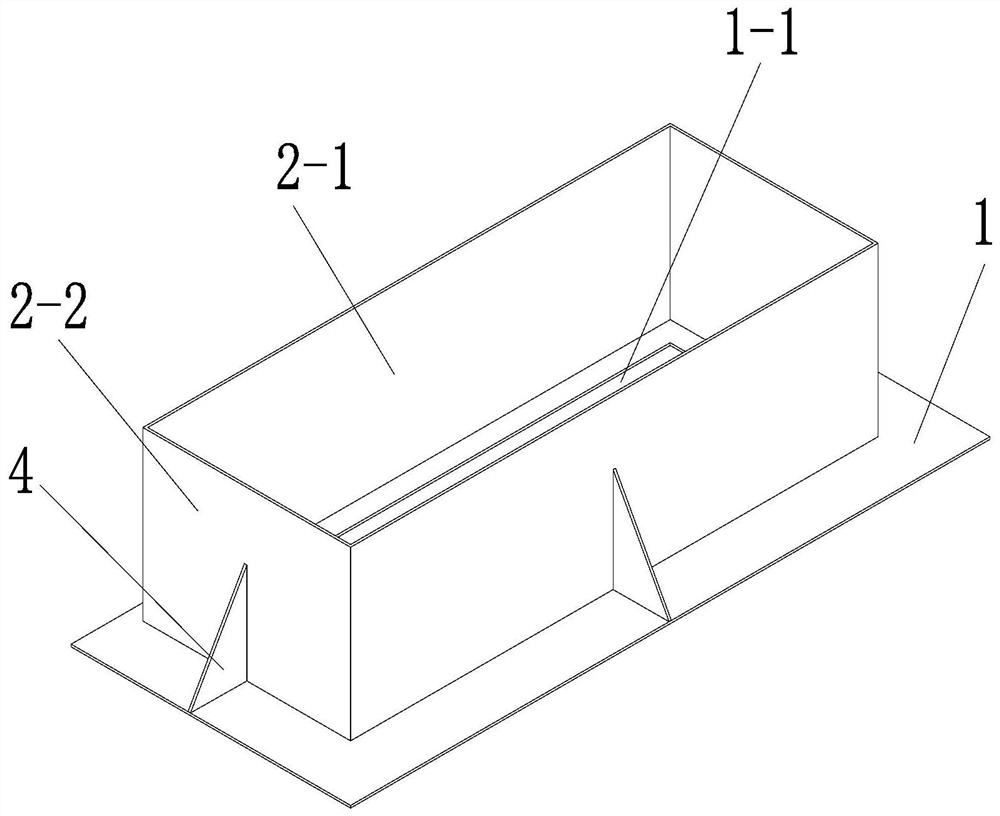

[0039] like figure 1 and figure 2 The shown vertical shaft bridge pierces the cast-in-place concrete floor for one-time forming construction method. The tooling used in this construction method includes a mold for forming the reserved hole of the vertical shaft bridge frame and a wooden formwork 6 for forming the cast-in-place concrete floor slab. The reserved hole for the shaft bridge frame is formed The mold includes a base plate 1, a coaming plate vertically fixedly installed on the base plate 1 and a cover plate 3 arranged at the top of the coaming plate. The center of the base plate 1 is provided with a shaft bridge passing hole 1-1. The external dimensions of the vertical shaft bridge through the hole 1-1 match the external dimensions of the vertical shaft bridge 5, and the cover plate 3 is provided with a fastening part that matches the inner surface of the coaming plate. The construction method includes the following steps :

[0040] Step 1. Forming of the cast-in-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com