Ignition method of double-discharge mode plasma igniter with multi-anode structure

A plasma and discharge mode technology, applied in the power field, can solve the problems of poor ignition reliability, low ignition energy utilization rate, and small ignition energy, and achieve the effects of wide lean burn limit, high working pressure, and stable ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

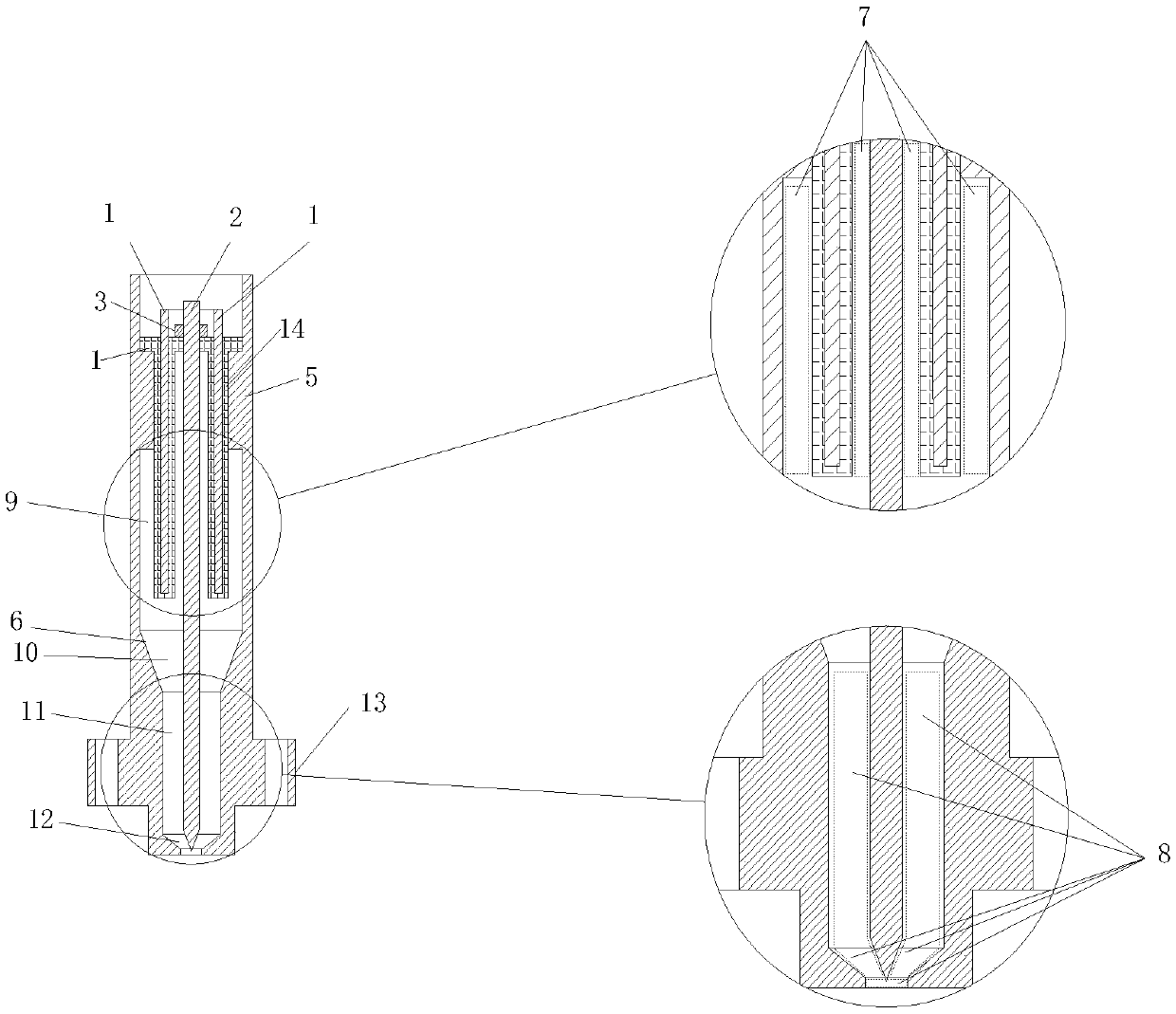

[0012] Embodiment 1: A kind of double discharge mode plasma igniter with multi-anode structure, the scheme structure is as follows figure 2 As shown, it includes a long anode 2 located in the center, a plurality of short anodes 1 located around, a ground electrode 5, an anode insulating positioning sleeve 4 and a fastening nut of the long anode 2; the long anode 2 is installed on the igniter center position, and fixed at the center position of the anode insulation positioning sleeve 4; the number of the short anode 1 is more than two, arranged in a ring outside the long electrode, and installed on the anode insulation positioning sleeve 4; the ground electrode 5 passes through the insulation The positioning sleeve 4 fixes the short anode 1 and the long anode 2 ; the fastening nut of the long anode 2 is used to fix the long anode 2 on the insulating positioning sleeve 4 . The lower end of the ground electrode 5 has a positioning flange 13 for installing the plasma igniter. Ac...

Embodiment 2

[0013] Embodiment 2: A double-discharge mode plasma igniter with a multi-anode structure, including a housing, a long anode 2, a short anode 1, an anode insulating positioning sleeve 4 and a ground electrode 5, and a ground electrode 5 is installed in the housing , the ground electrode 5 surrounds and forms a concave hollow cylinder, which is divided into two parts, the upper part includes a large-diameter value maintaining segment and the small-diameter value maintaining segment, and the lower part includes a first diameter value maintaining segment 9 and a first diameter value gradually decreasing segment 10 , the second diameter value maintenance section 11, the second diameter value gradually decreasing section 12, and the connection between the large diameter value maintenance section and the small diameter value maintenance section is formed by the ground electrode 5 to form a horizontal ring wall due to the rapid decrease of the diameter value, so The above-described ins...

Embodiment 3

[0017] Embodiment 3: This solution involves an igniter mainly composed of a plurality of short anodes located around, a long anode located in the center, a ground electrode, an anode insulating positioning sleeve and a long anode fastening nut.

[0018] Since the igniter communicates with the combustion chamber of the engine, combustible air-fuel mixture exists in the first ionization space and the second ionization space.

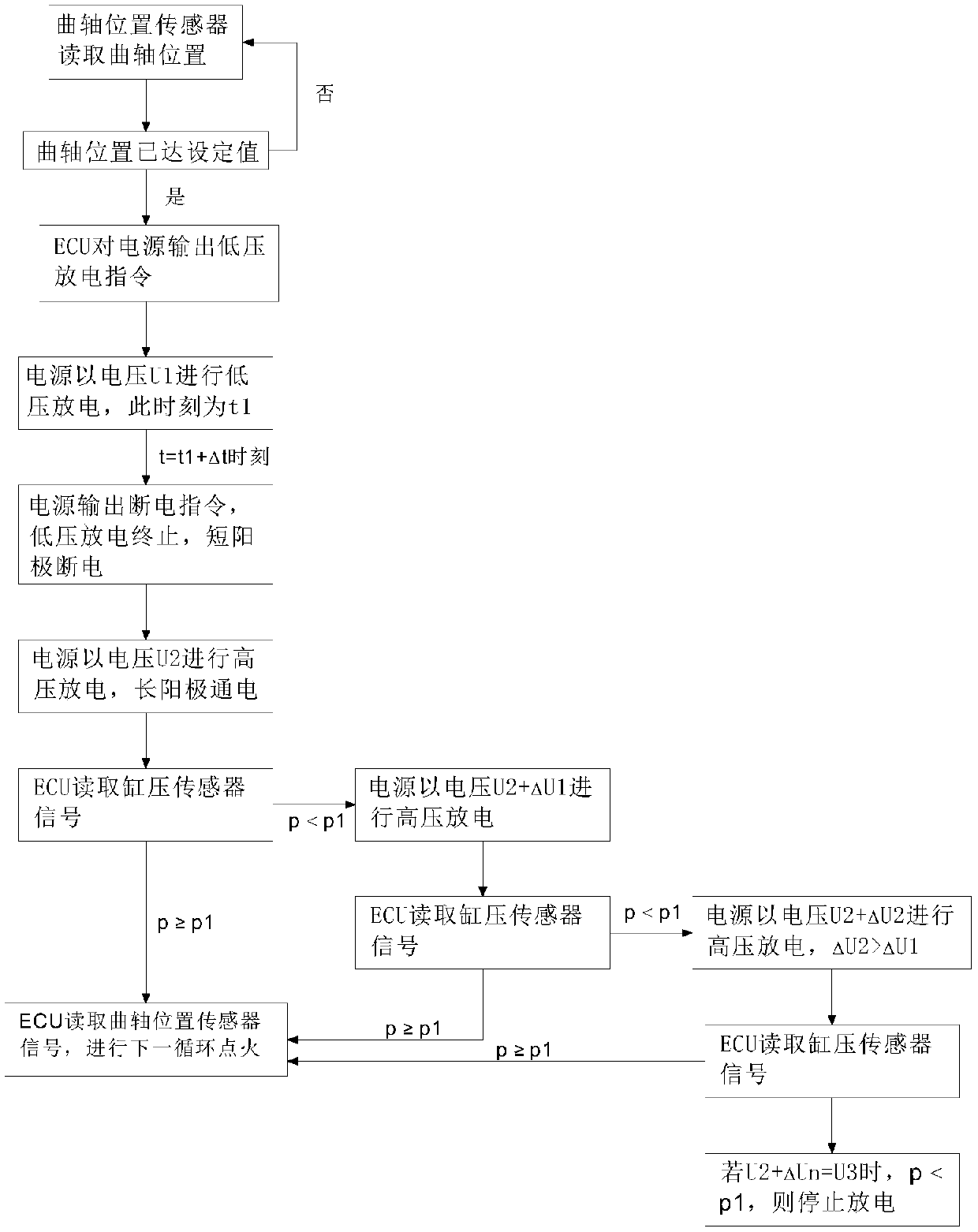

[0019] When working, the power supply first supplies power to the short anode with a lower voltage (for example: below 10,000 volts), and at this time the long anode is not powered; (At this time, it is equivalent to the ground electrode)-anode insulating positioning sleeve-short anode and a dielectric barrier discharge occurs, and the gas in the first ionization space is ionized under the action of an external electric field to generate free electrons and positively charged cations. Balanced plasma, increased chemical reactivity. Since the voltage is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com