Drawing test device and method for simulating full-length anchoring quality detection of roadway surrounding rock

A full-length anchoring and pull-out test technology, which is used in measurement devices, preparation of test samples, and testing of material strength by applying stable tension/compression. The application and influence of the reasonable design and effect evaluation of the bolt support, the force transmission mechanism and the deviation of the failure characteristics results, etc., to achieve the effect of high integration, avoidance of human error, and simple test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

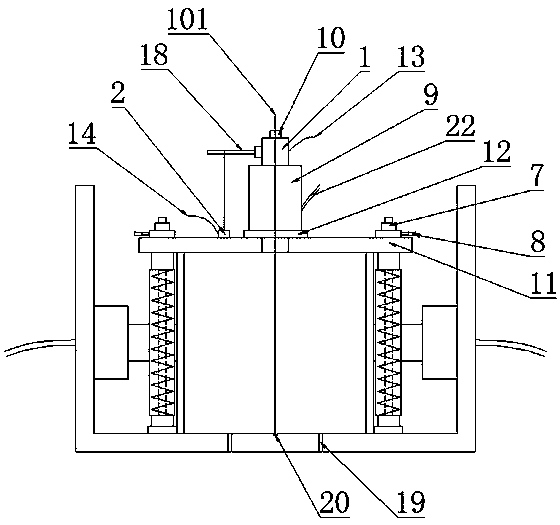

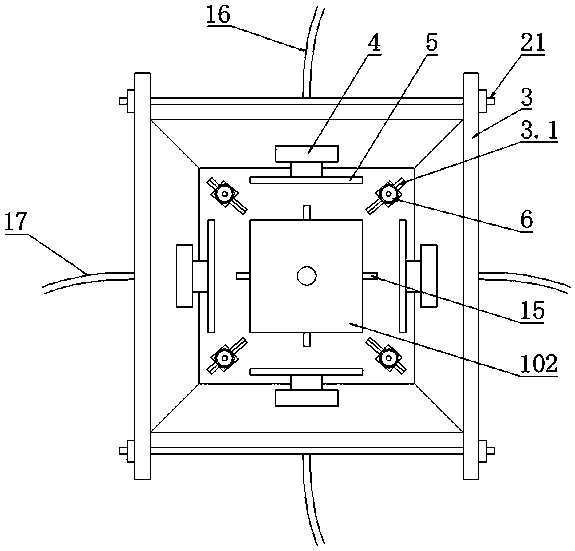

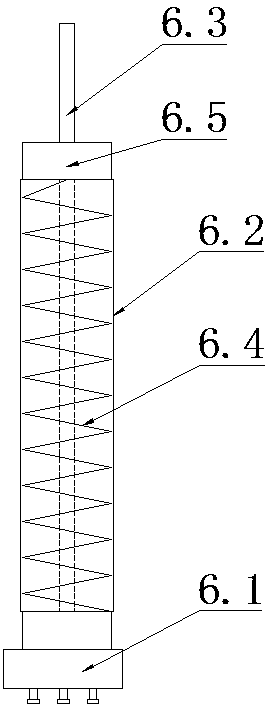

[0032]This embodiment provides a pullout test device for simulating the quality detection of the full-length anchorage of the roadway surrounding rock, including a simulated test box, a pullout system, a pressure sensor 1 for monitoring the pullout force during the pullout process of the bolt 101, and a The displacement sensor 2 that monitors the displacement of the anchor rod 101 in the drawing process and the computer system that is connected with the pressure sensor 1 and the displacement sensor 2 respectively through the data transmission wire; The hydraulic cylinder 4 controlled by hydraulic pressure, the surrounding pressure plate 5 and the telescopic spring tube 6 arranged on the movable end of the hydraulic cylinder 4; 3. In addition to being used to hold the cubic rock test block 102, it is also a counter force device; the number of hydraulic cylinders 4 is four, corresponding to the four sides of the cubic rock test block 102, and placed evenly around the cubic rock t...

Embodiment 2

[0047] This embodiment provides a pull-out test method for simulating the full-length anchorage quality detection of the surrounding rock of the roadway, which is implemented based on the pull-out test device for the full-length anchorage quality detection of the simulated roadway surrounding rock described in Example 1, including the following steps:

[0048] S1, put the cubic rock test block 102 prefabricated and maintained in advance into the cubic rock test block placement position in the box body 3, start the electro-hydraulic control switch of the hydraulic cylinder 4, and according to the simplified stress state of the anchor body, surround The pressure plate 5 exerts confining pressure on the cubic rock test block 102 under the push of the hydraulic cylinder 4. The application method is controlled by the stress rate, and the loading rate is between 0.01MPa / s-0.1MPa / s until the preset confining pressure is reached. Then stop, and maintain a steady state;

[0049] S2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com