Fluid mechanics experimental device

An experimental device and fluid mechanics technology, applied in teaching models, educational appliances, instruments, etc., can solve problems such as time-consuming maintenance, long time to read experimental data, and inability to meet the experimental conditions of curved or coiled pipes, etc. Achieve the effect of improving visibility and compatibility, solving single experimental object, and convenient and quick assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

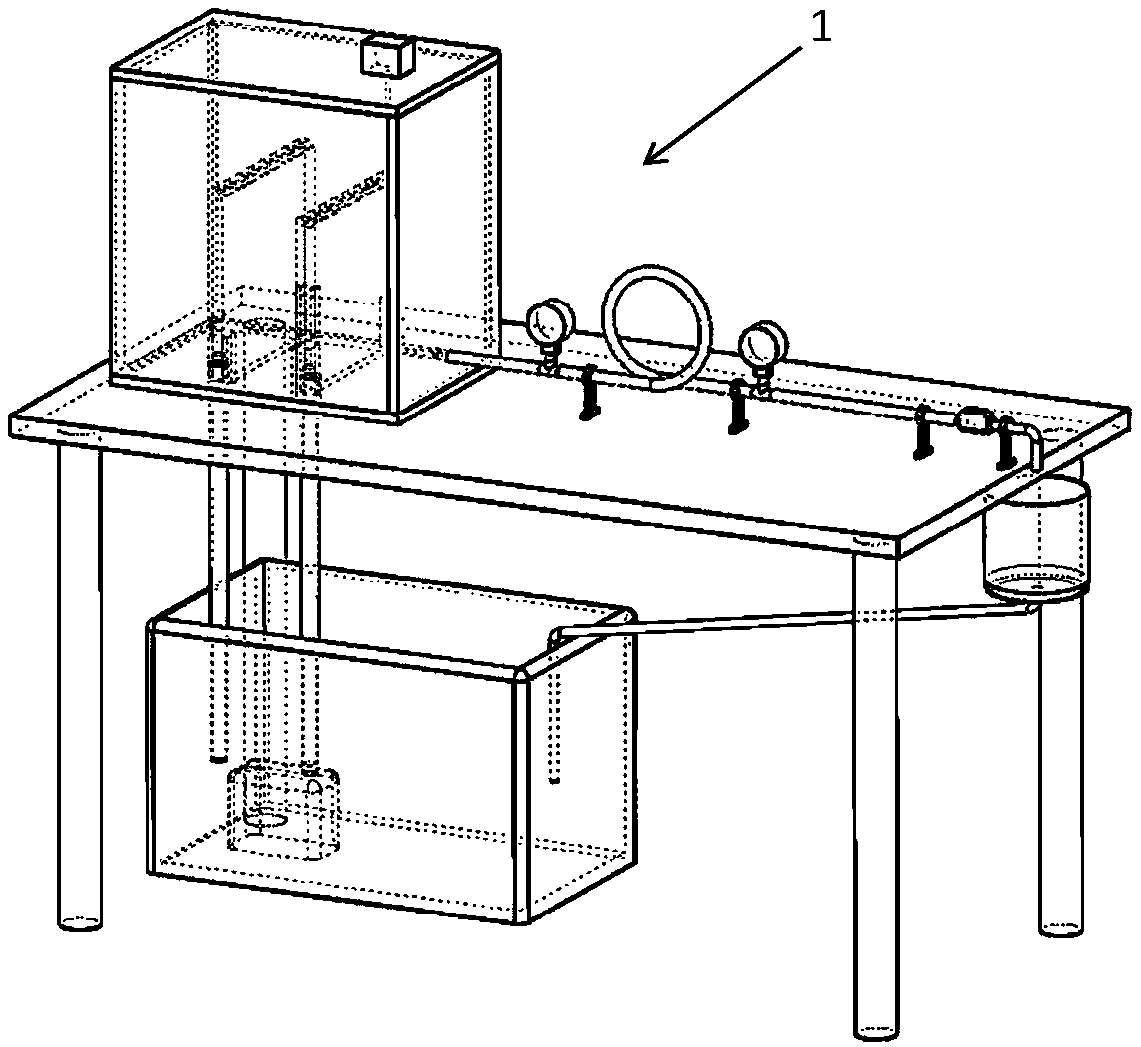

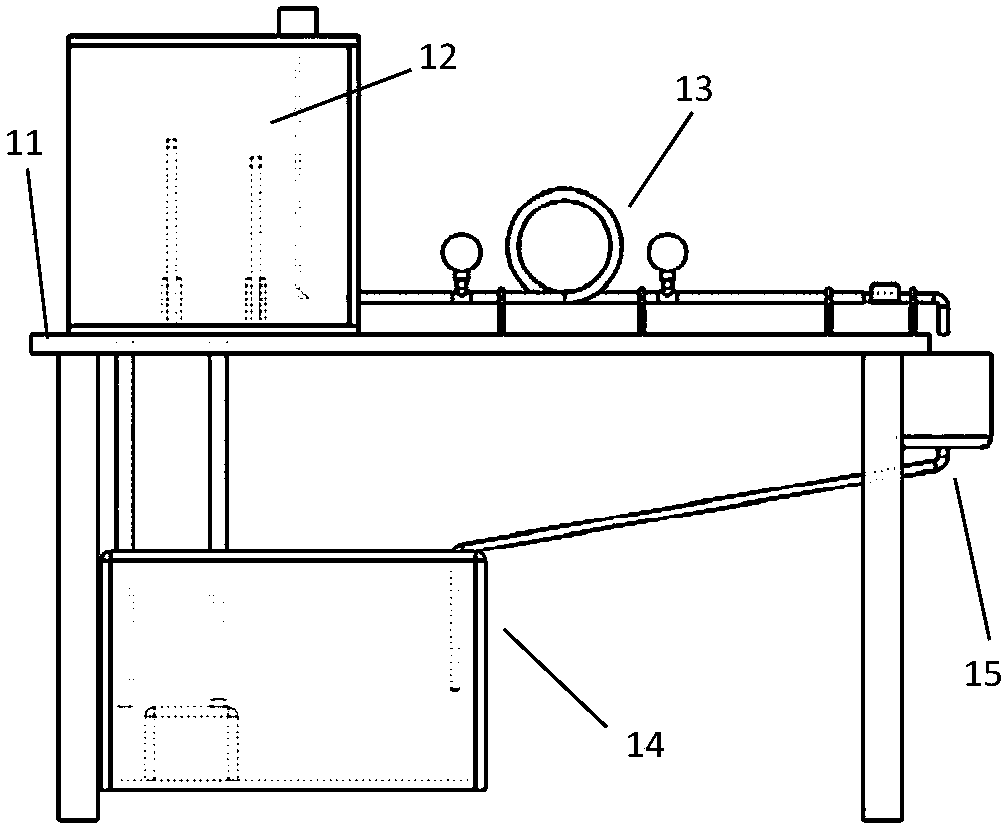

[0039]A kind of fluid mechanics experimental device 1, its structure is as figure 1 and figure 2 As shown, it includes a test bench 11, a test bench support, a water supply tank system 12, a measuring pipeline system 13, a water collection tank system 14 and a collection and return system 15, and the test bench 11 is fixedly connected to the test bench support.

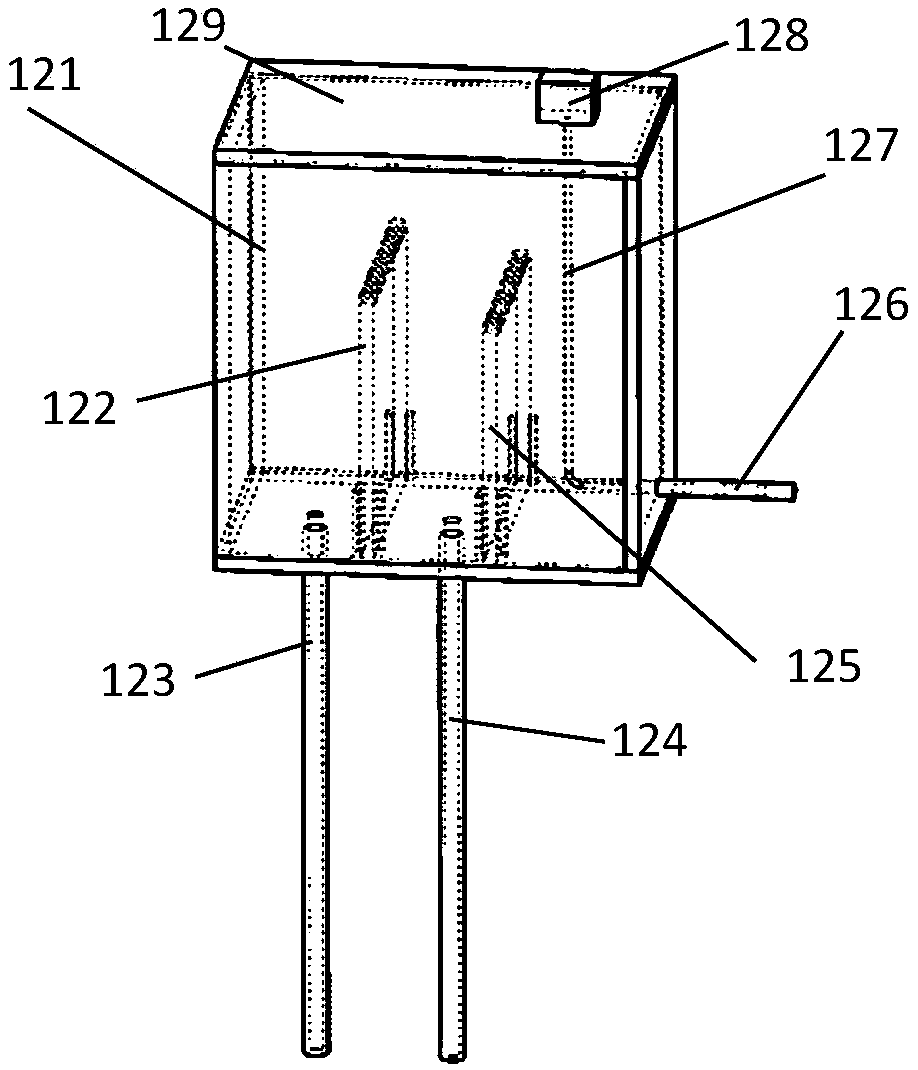

[0040] The water supply tank system 12 is placed on the test bench 11, and its structure is as follows: image 3 As shown, the internal components are drawn with dotted lines; the water supply tank system 12 includes a water supply tank 121, an overflow partition 122, a baffle 125, a water supply pipe 124, an overflow return pipe 123, a water outlet pipe 126, a water tank cover 129, colored The water box 128 and the colored water pipe 127; the water supply tank 121 is placed on the test bench 11; the overflow partition 122 and the divider 125 are respectively fixed in the water supply tank 121, and the height of the...

Embodiment 2

[0049] The difference between this embodiment and the connection method of Embodiment 1 is that the position of the pipe fixing bracket 132 and the test bench 11 can be adjusted. The fixing bracket 132 is slidably connected to the guide rail, and is fixed on the guide rail through a quick release buckle.

[0050] When it is necessary to adjust the installation position of the pipe fixing bracket 132, open the quick release buckle, move the pipe fixing bracket 132 along the guide rail, adjust the pipe fixing bracket 132 to a suitable position according to the shape and position of the experimental tube to be tested, and put the quick release When the buckle is closed and fastened, the pipeline fixing bracket 132 will be fixed on the guide rail, so that the position of the pipeline fixing bracket 132 relative to the test bench 11 is fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com