Tower-type grain three-section drying machinery

A three-stage, grain technology, applied in dryers, drying, grain drying and other directions, can solve the problems of uneven moisture, high waist burst rate, high energy consumption, etc., to reduce loss, increase utilization, increase Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

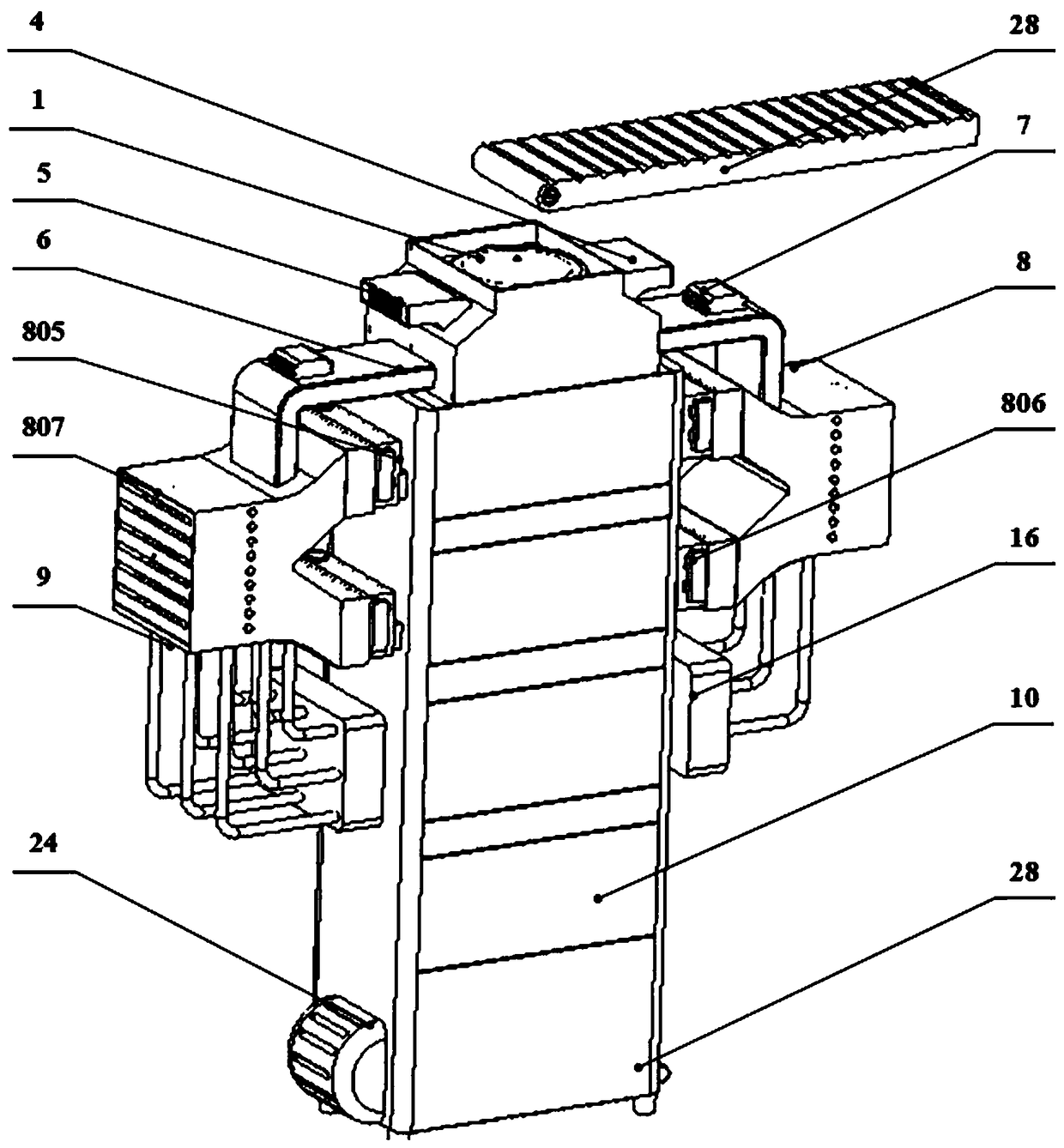

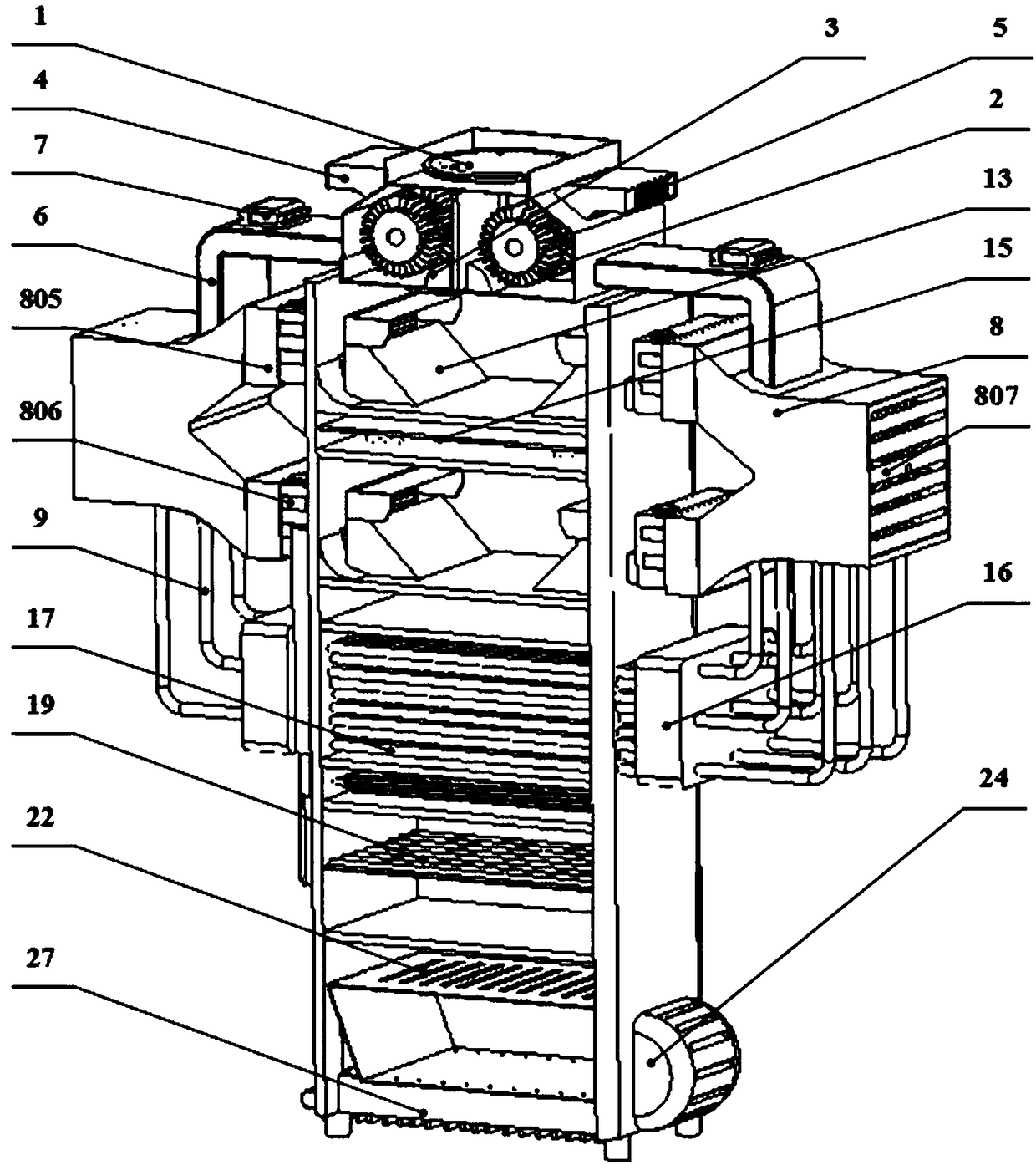

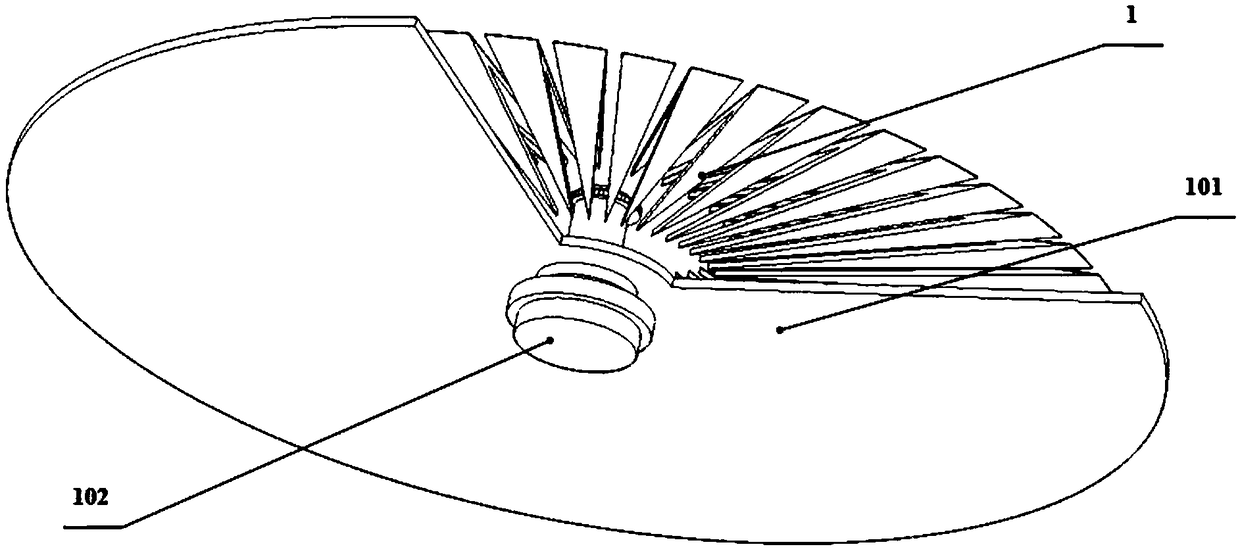

[0035] Please also refer to Figure 1 to Figure 12 , a tower-type grain three-stage drying machine provided by an embodiment of the present invention, including a material distribution device 1, a material distribution tray 101, a rotating shaft 102, a roller brush 2, an air supply port I3, an air outlet pipe 4, and a screen 5. Air supply pipe 6, temperature control device 7, variable temperature heating device 8, fan 801, heating pipe 802, rotating shaft I 803, windshield 804, control valve 805, filter screen 806, water pipe 9, housing 10, connecting plate Ⅰ11, conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com