A synthetic adhesive three-layer composite non-woven self-adhesive elastic bandage and preparation method thereof are provide

An elastic bandage and non-woven fabric technology, applied in bandages, layered products, non-adhesive dressings, etc., can solve the problems of soft touch without high temperature resistance, sweat absorption ability, skin allergies, etc., to achieve good elasticity, good soft touch, good The effect of self-adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of a synthetic glue three-layer composite non-woven self-adhesive elastic bandage, comprising the following steps:

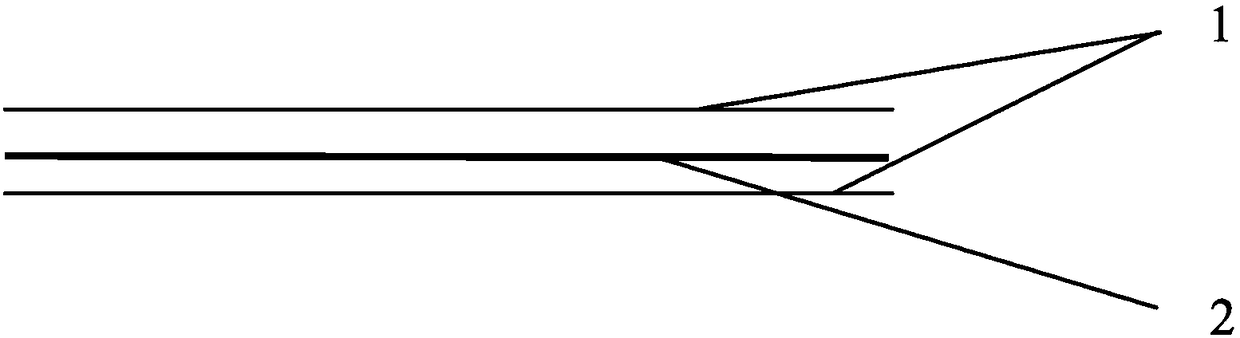

[0024] 1) Add a certain thickness of impregnated non-woven elastic fabric into elastic spandex yarn through the stitch-bonding process to form a stitch-bonded impregnated non-woven elastic fabric base material;

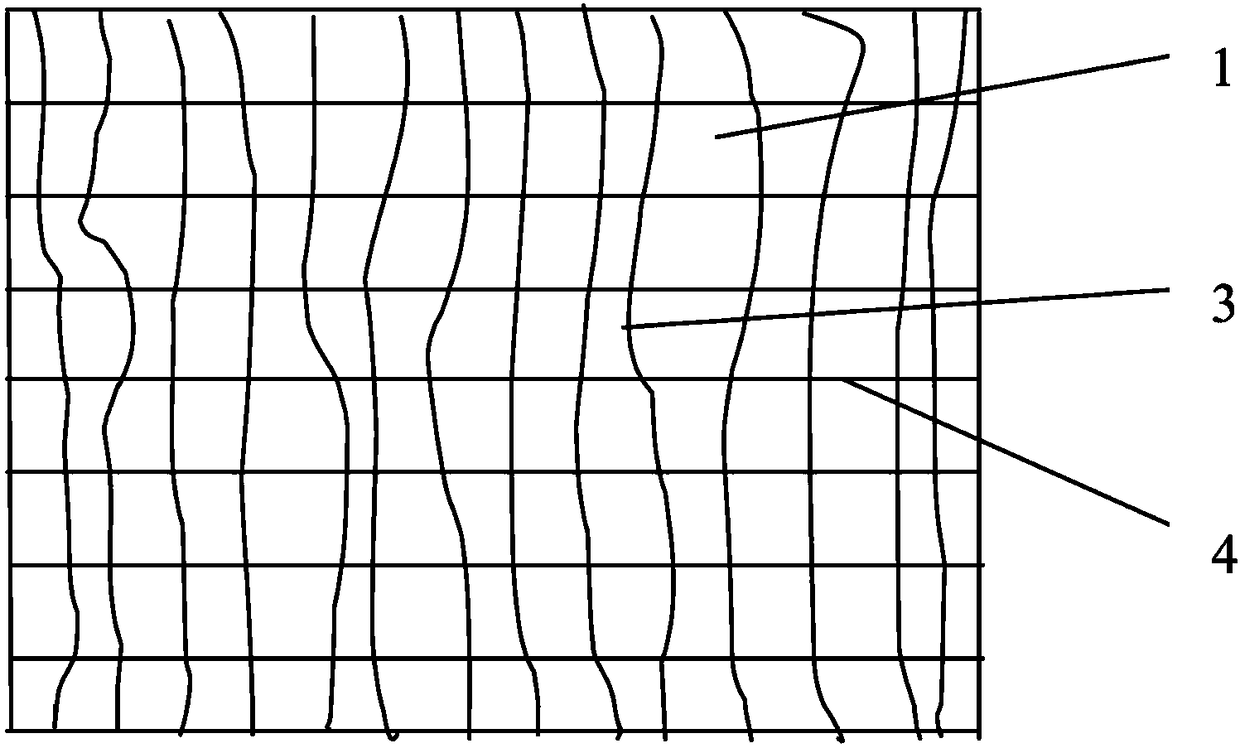

[0025] 2) The two-layer stitch-bonded and impregnated non-woven elastic fabric base material is wrapped with a certain thickness of non-elastic hot-rolled non-woven fabric through the composite process, and a protein-free composite adhesive is used to form a synthetic three-layer composite non-woven fabric. Fabric substrate for viscoelastic bandages;

[0026] 3) after coating the latex-free synthetic glue on the cloth base material for drying, the semi-finished product of the synthetic glue three-layer composite non-woven self-adhesive elastic bandage is obtained;

[0027] 4) The semi-finished product is processed according ...

Embodiment 1

[0029] 1) Production preparation

[0030] a. Prepare the base material of the bandage, which is two layers of impregnated non-woven fabric and one-time hot-rolled non-woven fabric;

[0031] b. Prepare the composite adhesive for the base material of the bandage, which has no protein component;

[0032] c. Prepare the latex-free synthetic glue for bandage products;

[0033] 2) Composite fabric

[0034] a. Add a certain thickness of impregnated non-woven fabric to elastic spandex yarn through the stitch-bonding process to form a stitch-bonded impregnated non-woven elastic fabric base material;

[0035] b. Two layers of stitch-bonded and impregnated non-woven elastic fabrics are wrapped with a certain thickness of non-elastic hot-rolled non-woven fabrics through a special compounding process, and compounded with a protein-free compound adhesive;

[0036] 3) gluing

[0037] The synthetic adhesive is evenly coated on the fabric substrate by dipping, spraying, scraping, etc. for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com