Deep purifying method and device of air pollutants generated during spraying of oil paint

A technology of air pollutants and deep purification, which is applied in the field of environmental engineering, can solve problems such as the inoperability of sticky equipment, and achieve the effects of avoiding equipment corrosion, no secondary pollution, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

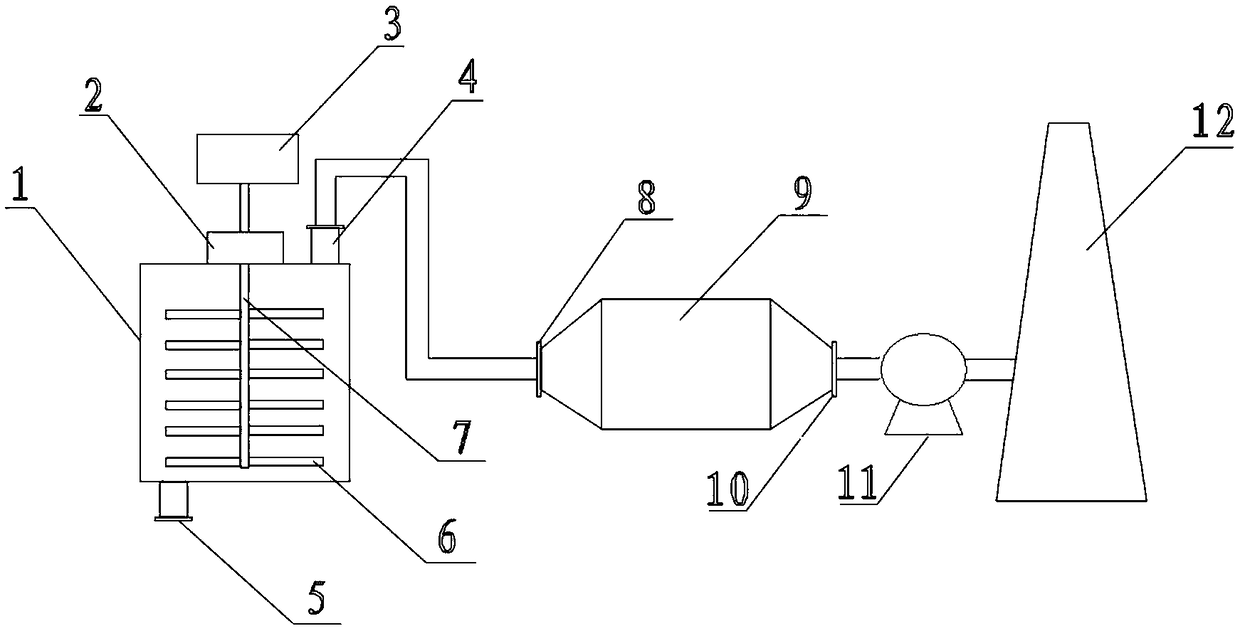

Method used

Image

Examples

Embodiment 1

[0038] A mixture of stainless steel metal balls with a diameter of 20 mm and a stainless steel metal ball with a diameter of 30 mm with a mass ratio of 1:1 was put into the inner cavity of the paint mist filter, and the whole set of devices was connected.

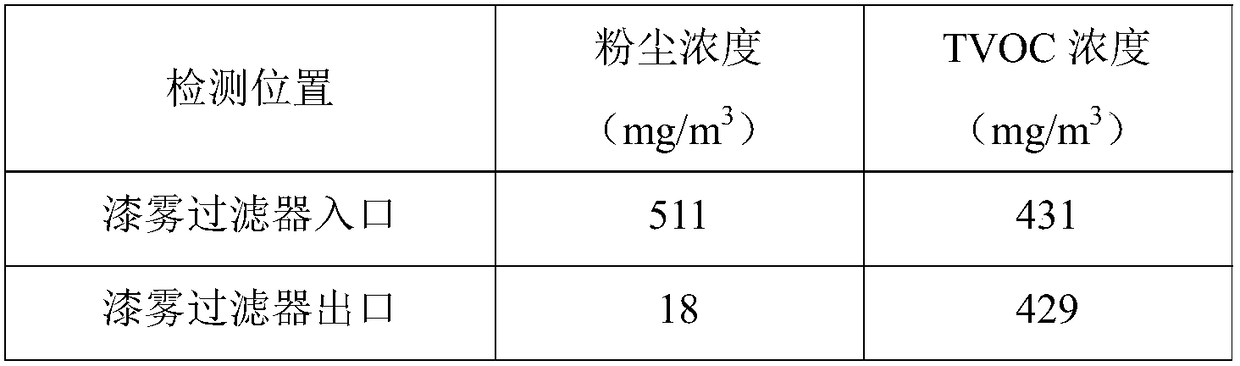

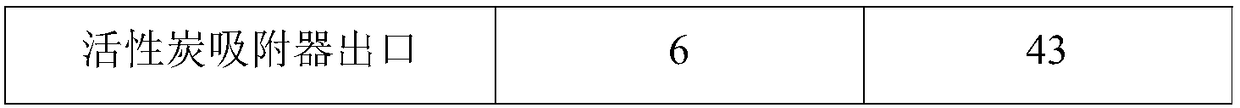

[0039] 1000m generated by the paint shop 3 / h The spraying exhaust gas is collected through the pipeline and sent to the cavity of the paint mist filter filled with stainless steel metal balls. The spraying exhaust gas passes through the filter medium from bottom to top, and the solid paint mist substances in the spraying exhaust gas are adhered to the stainless steel metal balls. On the surface, the gaseous pollutants in the spray paint exhaust gas pass through the stainless steel metal ball and escape from the upper part of the paint mist filter; at the same time, start the stirring device in the paint mist filter to stir the stainless steel metal ball. The paint mist attached to the surface of the stainless steel metal b...

Embodiment 2

[0047] A mixture of plastic balls with a diameter of 20 mm and a plastic ball with a diameter of 30 mm with a mass ratio of 1:1 was put into the inner cavity of the paint mist filter, and the whole set of devices was connected.

[0048] 1000m of spraying exhaust gas produced by the spraying workshop 3 / h is collected through the pipeline and sent to the cavity of the paint mist filter filled with plastic balls. The spraying exhaust gas passes through the filter medium from bottom to top, and the solid paint mist substances in the spraying exhaust gas are adhered to the surface of the plastic balls, and the spraying exhaust gas The gaseous pollutants in the paint escape from the upper part of the paint mist filter after passing through the plastic balls; at the same time, start the stirring device in the paint mist filter to stir the plastic balls, the speed of the stirring device is 5rpm, and the paint waste gas is processed by the paint mist filter After that, it is sent to t...

Embodiment 3

[0055] A mixture of ceramic balls with a diameter of 20 mm and a ceramic ball with a diameter of 30 mm with a mass ratio of 1:1 was put into the inner cavity of the paint mist filter, and the whole set of devices was connected.

[0056] 1000m of spraying exhaust gas produced by the spraying workshop 3 / h is collected through the pipeline and sent to the cavity of the paint mist filter filled with ceramic balls. The spraying exhaust gas passes through the filter medium from bottom to top, and the solid paint mist substances in the spraying exhaust gas are adhered to the surface of the ceramic balls, and the spraying exhaust gas The gaseous pollutants in the paint escape from the upper part of the paint mist filter after passing through the ceramic ball; at the same time, start the stirring device in the paint mist filter to stir the ceramic balls, and the speed of the stirring device is 5rpm; the paint spraying waste gas is processed by the paint mist filter After that, it is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com