Grader for coffee beans and grading method

A technology for coffee beans and a classifier, which is applied in the direction of solid separation and the like, can solve the problems of difficulty in grading the color and quality of roasted coffee beans, and difficulty in grading the size and quality of green coffee beans, and achieves the effect of reducing labor intensity and improving sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

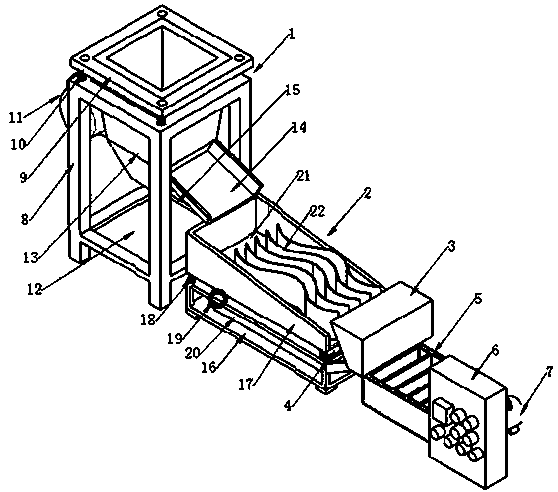

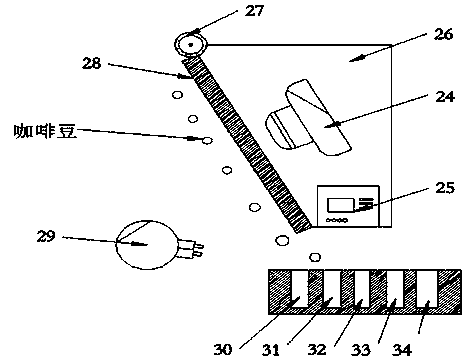

[0049] Embodiment 1: as Figure 1~5 As shown, a coffee bean classifier includes a feeding part 1, an even material screening part 2, a classifying part 3, an air blowing part 4, a receiving part 5, an electric control box 6, an air pump 7, and the feeding part 1 and The even material screening part 2 is connected,

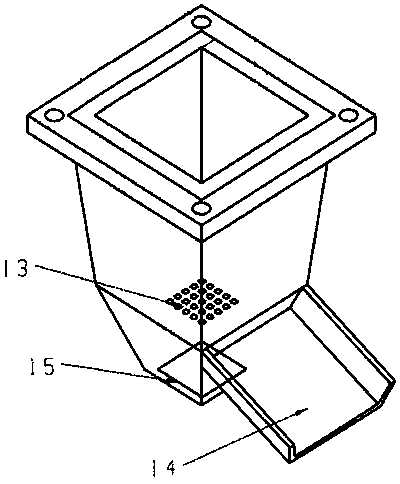

[0050] The feeding part 1 includes a frame I8, a hopper 9, a vibration motor I11, and an impurity collector I12. The frame I8 is a rectangular frame structure. The top of the hopper 9 is installed on the top of the frame I8 through the hopper installation component 10, and the lower part of the hopper 9 extends In the frame I8, the vibration motor I11 is fixed on the side wall of the hopper 9, the impurity collector I12 is fixed horizontally on the bottom of the frame I8, and the discharge port 14 of the hopper 9 is installed obliquely on the side of the bottom of the hopper 9. The lower end of the wall and the discharge port 14 communicates with the even material...

Embodiment 2

[0060]Embodiment 2: A kind of method for classifying coffee beans, coffee beans are green coffee beans, classify according to the particle diameter of coffee beans, adopt the coffee bean classifier of embodiment 1 to classify, concrete steps are as follows:

[0061] (1) Put the coffee beans into the hopper of the feeding part, and realize the preliminary screening under the vibration of the vibration motor Ⅰ. The pre-screened adulterants pass through the bottom screen Ⅰ at the bottom of the hopper and enter the adulterant outlet. The impurities fall into the adulterant collector Ⅰ through the adulterant outlet under the action of gravity, and the preliminary screened coffee beans stay above the bottom screen Ⅰ and pass through the outlet of the hopper under the vibration and gravity of the vibration motor Ⅰ Enter the main body of the vibrating bed in the leveling and screening part;

[0062] (2) The pre-screened coffee beans in the vibrating bed main body of the homogenizing a...

Embodiment 3

[0065] Embodiment 3: A kind of coffee bean classification method, coffee beans are roasted coffee beans, carry out classification according to the color of roasted coffee beans, adopt the coffee bean classification machine of embodiment 1 to carry out classification, concrete steps are as follows:

[0066] (1) Put the coffee beans into the hopper of the feeding part, and realize the preliminary screening under the vibration of the vibration motor Ⅰ. The pre-screened adulterants pass through the bottom screen Ⅰ at the bottom of the hopper and enter the adulterant outlet. The impurities fall into the adulterant collector Ⅰ through the adulterant outlet under the action of gravity, and the preliminary screened coffee beans stay above the bottom screen Ⅰ and pass through the outlet of the hopper under the vibration and gravity of the vibration motor Ⅰ Enter the main body of the vibrating bed in the leveling and screening part;

[0067] (2) The pre-screened coffee beans in the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com