Casting method of large-caliber high-pressure flat valve

A large-diameter, flat valve technology, applied in casting molding equipment, molds, mold components, etc., can solve the problems of large valve body size, shrinkage holes, cracks, sand pores, slag holes, and large process mud cores. To achieve the effect of meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

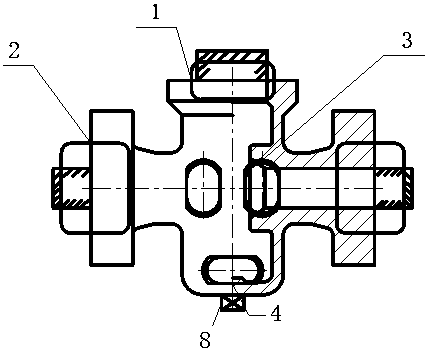

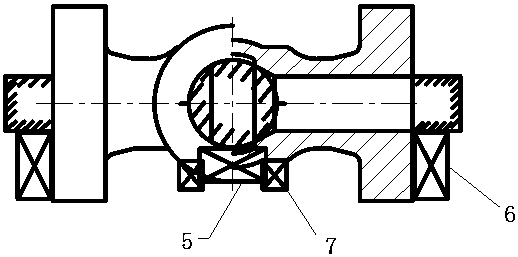

[0018] Such as Figure 1-2 As shown, it adopts furan resin sand molding and cold box resin core, and its characteristics are: install No. Round heating and heat preservation riser 2, install No. 3 round waist heating and heat preservation riser 3 symmetrically on the valve waist where the side flange and valve belly are connected, and install No. 4 waist round heating and heat preservation riser 4 at the bottom of the valve body , and place No. 1 forming chiller 5 chilling on the bottom top surface of the middle flange, place No. 2 forming chilling iron 6 chilling on the bottom top surface of the symmetrical flange at both ends, and place No. 3 chilling iron on the bottom of the valve waist Forming cold iron 7 is quenched, and No. 4 forming cold iron 8 is placed on the bottom of the valve body to quench.

[0019] Furthermore, it installs A×2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com