3D five-layer positioning illusive color down jacket channel fabric

A down jacket and layer positioning technology, which is applied in the field of down jacket equipment, can solve the problems of inability to realize color sense, sense of technology, sense of novelty, sense of fashion, inability to effectively improve the shape and stripes of down jackets, comfort of anti-chorfing film and poor toughness, etc. , to achieve the effect of improving visual sense, good airtightness and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

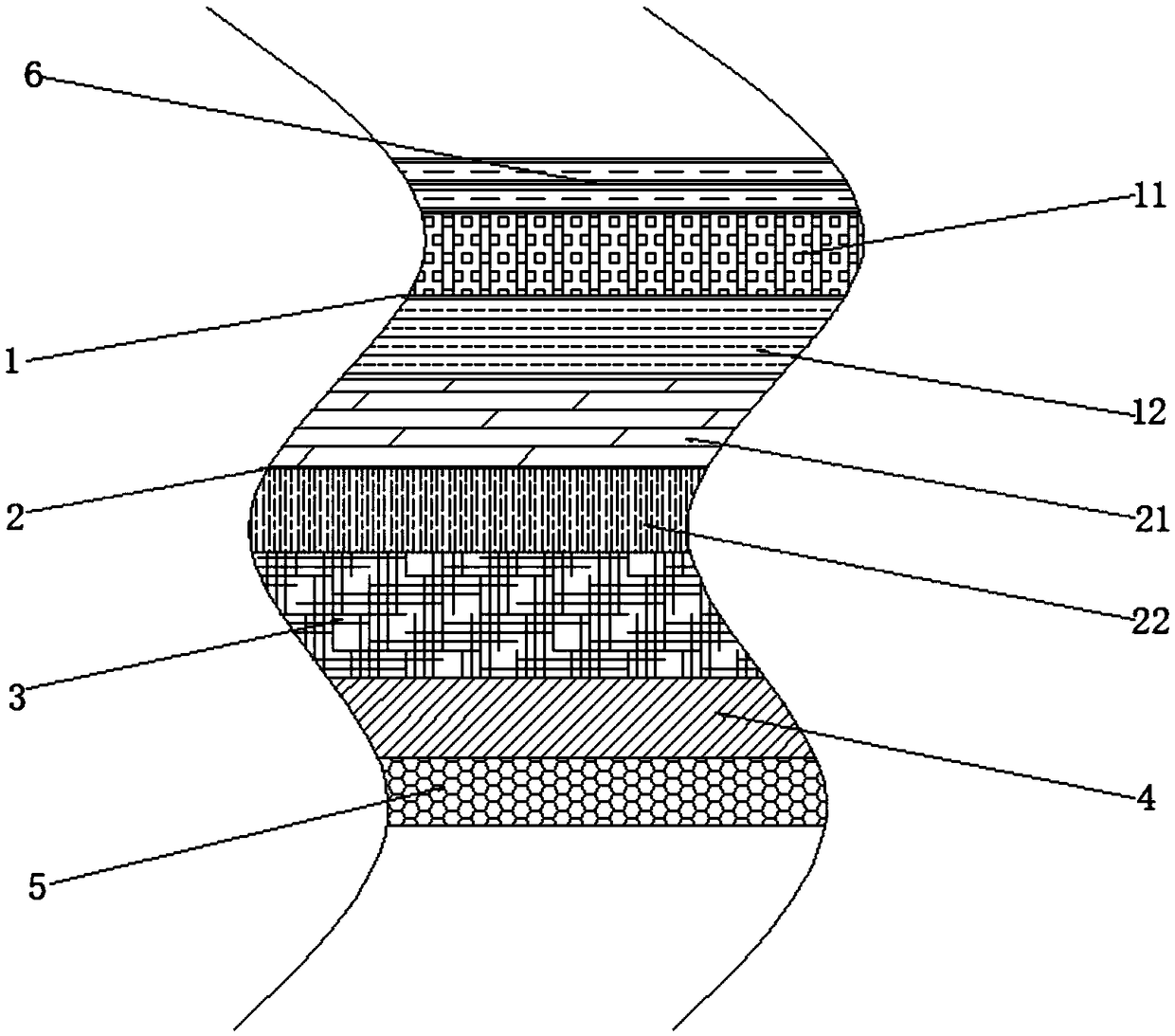

[0027] A 3D five-layer positioning phantom color down jacket channel fabric, comprising a first combination layer 1, a main fabric layer 11, a first anti-velvet film 12, a second combination layer 2, a base fabric layer 21, a second anti-velvet film 22, a color Membrane 3, sweat-absorbing layer 4, breathable layer 5 and waterproof layer 6, one side of the first combined layer 1 is glued and connected with one side of the waterproof layer 6, the other side of the first combined layer 1 is glued and connected with one side of the second combined layer 2, The other side of the second combined layer 2 is glued to one side of the color film 3, the other side of the color film 3 is glued to one side of the sweat-absorbing layer 4, and the other side of the sweat-absorbing layer 4 is glued to one side of the air-permeable layer 5;

[0028] Wherein, the first combined layer 1 comprises the main fabric layer 11 and the first velvet-proof film 12, the first combined layer 1 is formed by ...

Embodiment 2

[0042] A 3D five-layer positioning phantom color down jacket channel fabric, comprising a first combination layer 1, a main fabric layer 11, a first anti-velvet film 12, a second combination layer 2, a base fabric layer 21, a second anti-velvet film 22, a color Membrane 3, sweat-absorbing layer 4, breathable layer 5 and waterproof layer 6, one side of the first combined layer 1 is glued and connected with one side of the waterproof layer 6, the other side of the first combined layer 1 is glued and connected with one side of the second combined layer 2, The other side of the second combined layer 2 is glued to one side of the color film 3, the other side of the color film 3 is glued to one side of the sweat-absorbing layer 4, and the other side of the sweat-absorbing layer 4 is glued to one side of the air-permeable layer 5;

[0043]Wherein, the first combined layer 1 comprises the main fabric layer 11 and the first velvet-proof film 12, the first combined layer 1 is formed by b...

Embodiment 3

[0057] A 3D five-layer positioning phantom color down jacket channel fabric, comprising a first combination layer 1, a main fabric layer 11, a first anti-velvet film 12, a second combination layer 2, a base fabric layer 21, a second anti-velvet film 22, a color Membrane 3, sweat-absorbing layer 4, breathable layer 5 and waterproof layer 6, one side of the first combined layer 1 is glued and connected with one side of the waterproof layer 6, the other side of the first combined layer 1 is glued and connected with one side of the second combined layer 2, The other side of the second combined layer 2 is glued to one side of the color film 3, the other side of the color film 3 is glued to one side of the sweat-absorbing layer 4, and the other side of the sweat-absorbing layer 4 is glued to one side of the air-permeable layer 5;

[0058] Wherein, the first combined layer 1 comprises the main fabric layer 11 and the first velvet-proof film 12, the first combined layer 1 is formed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com