Cell phone cover plate screen printing device

A cover wire and cell phone technology, applied in printing devices, screen printing, printing, etc., can solve the problems of unsuitable high-efficiency models, high cost of vacuum suction cups, increased waste of resources, etc., to increase the success of screen printing Probability, convenient and simple disassembly and assembly, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

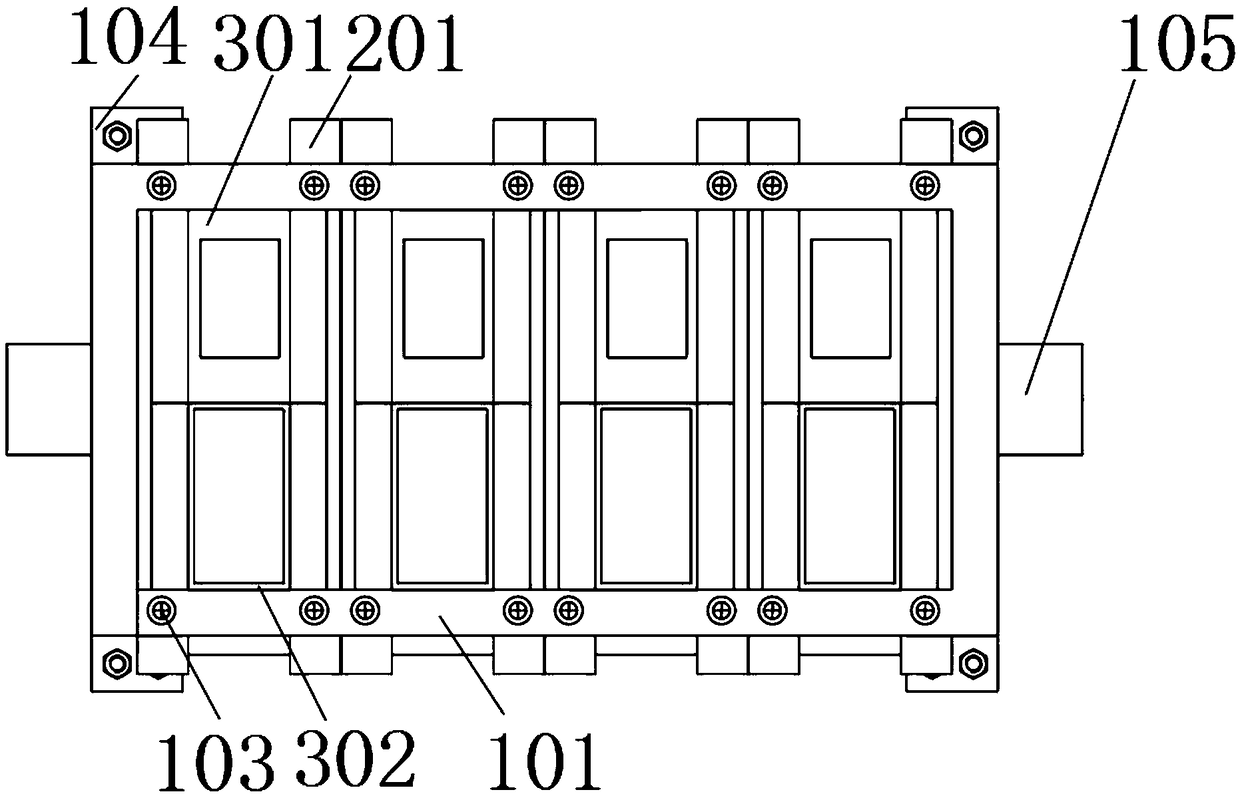

[0024] figure 1 As shown, a mobile phone cover screen printing device includes a screen printing seat plate 101 installed on the upper surface of the working table of the screen printing machine and hollowed out on the surrounding surface. The front and rear end hollow surfaces of the screen printing seat plate 101 are interspersed with multiple sets of No. 1 cards. Board 201 and No. 2 card board 202, No. 1 card board 201 and No. 2 card board 202 are matched one by one, the ends of No. 1 card board 201 and No. A No. 1 limiting plate 301 and a sitting wall 303 are closely placed in the gap between the plate 201 and the No. 2 clamping plate 202, and the upper middle part of the No. 1 limiting plate 301 and the No. 2 limiting plate 302 is provided with a limiting groove 304, and Both sides of the upper end of No. 1 limiting plate 301 and No. 2 limiting plate 302 are fixedly installed with sitting walls 303 stuck on the surface of No. 1 clamping plate 201 or No. 2 clamping plate 2...

Embodiment 2

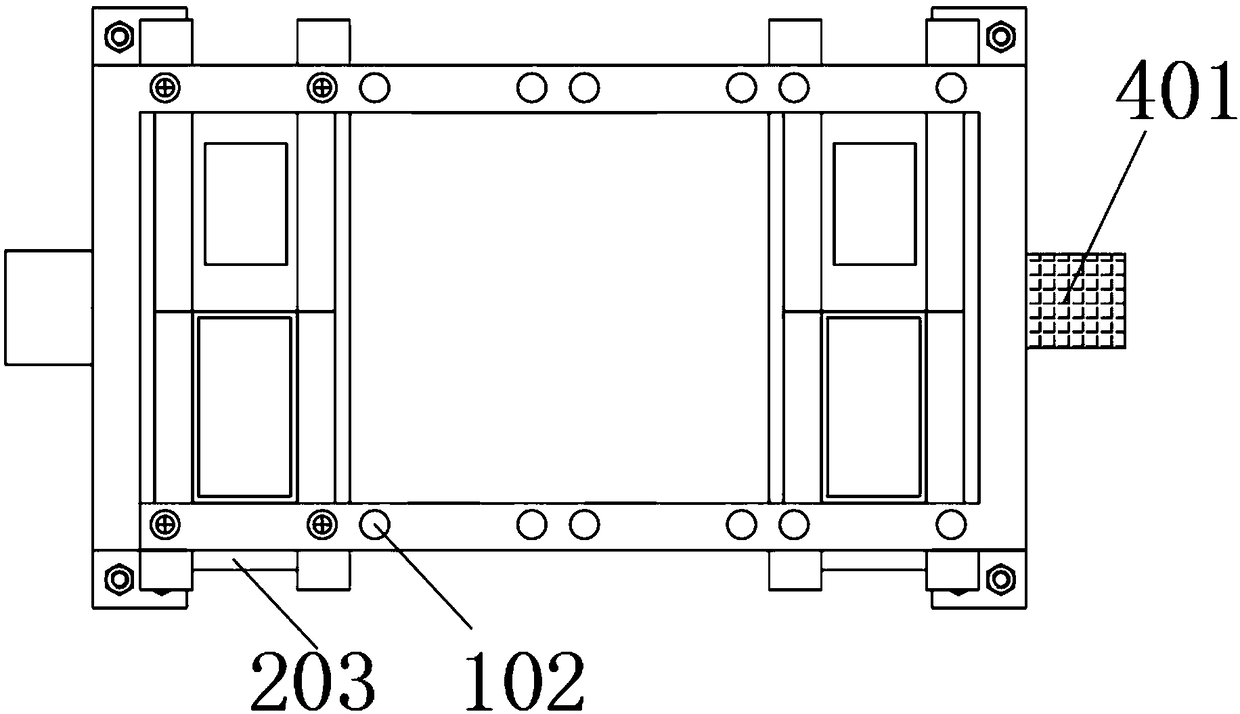

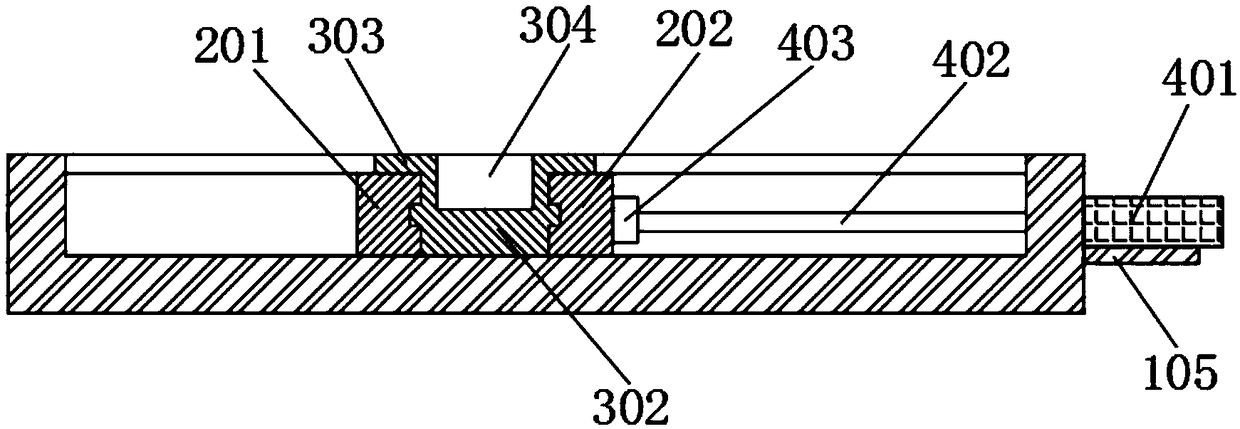

[0026] On the basis of above-mentioned embodiment 1, as figure 2 and image 3 As shown, people can release the fastening of the fixing screw 103, use bolts or the like to fix and install the cylinder part 401 on the surface of the cylinder placement plate 105, and punch holes on the corresponding side, and the assembly output rod 402 of the cylinder part 401 passes through the connecting block 403 It is fixedly connected with the No. 2 clamp 202, and the connection block 403 and the No. 2 clamp 202 can be bolted or glued. The connection mode between the connection block 403 and the output rod 402 is preferably threaded, that is, at the connection block 403 Threaded holes are drilled in the center, which is easy to do in the prior art. In this example, it should be noted that the assembly output rod 402 of the left and right cylinder parts 401 should not be installed on the supporting No. 1 pallet 201 and No. 2 pallet 202. superior,( figure 2 The structural diagram of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com