A trolley bus power receiving system

A trolleybus and electric system technology, applied in the direction of electric vehicles, collectors, vehicle components, etc., can solve the problems of difficult operation, difficult adjustment, and time-consuming for the driver, so as to improve the efficiency of entering and exiting stations, save operating time, The effect of more charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

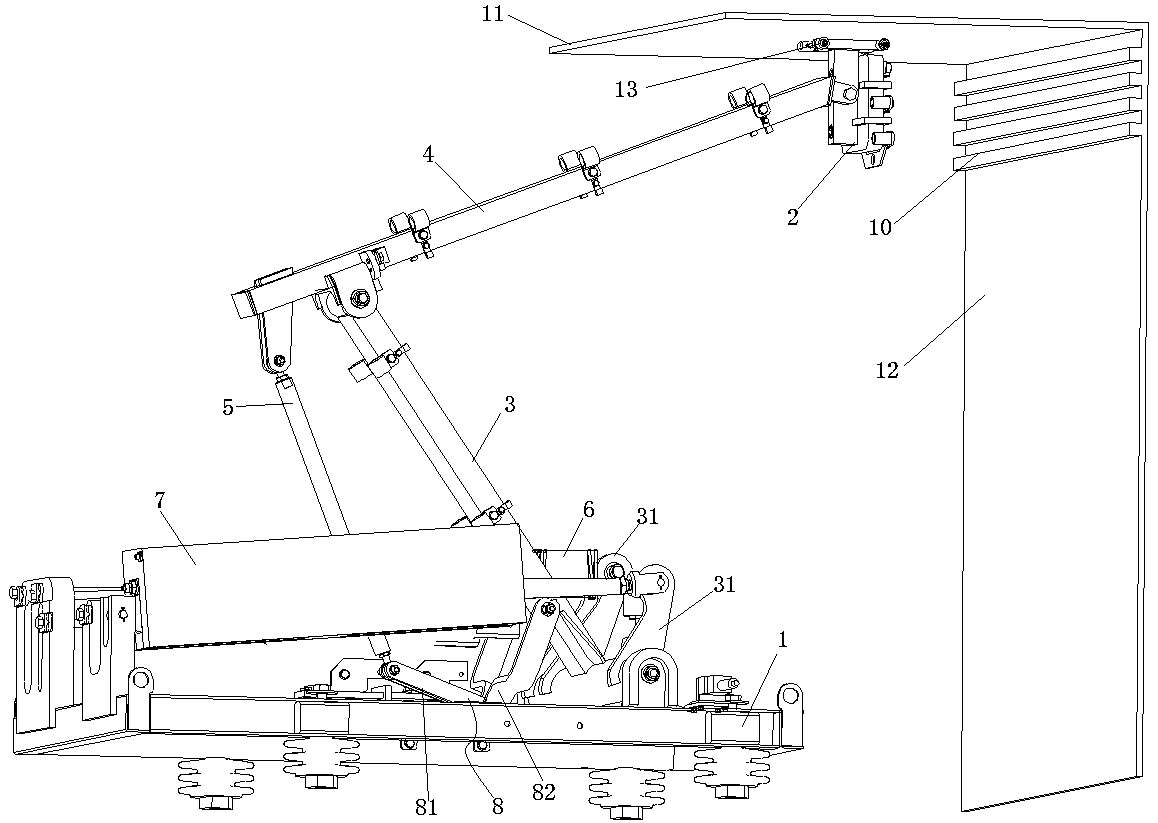

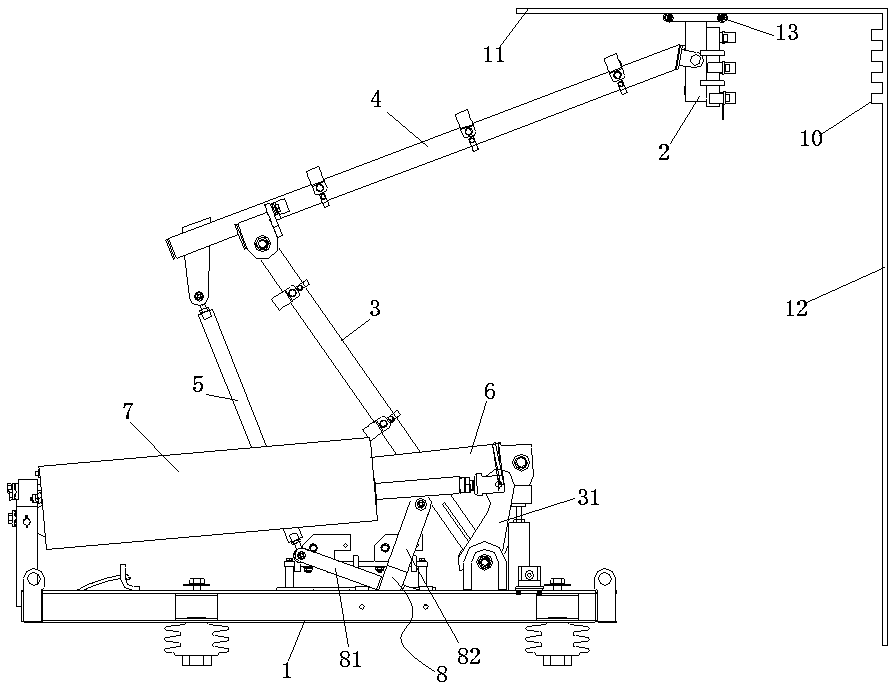

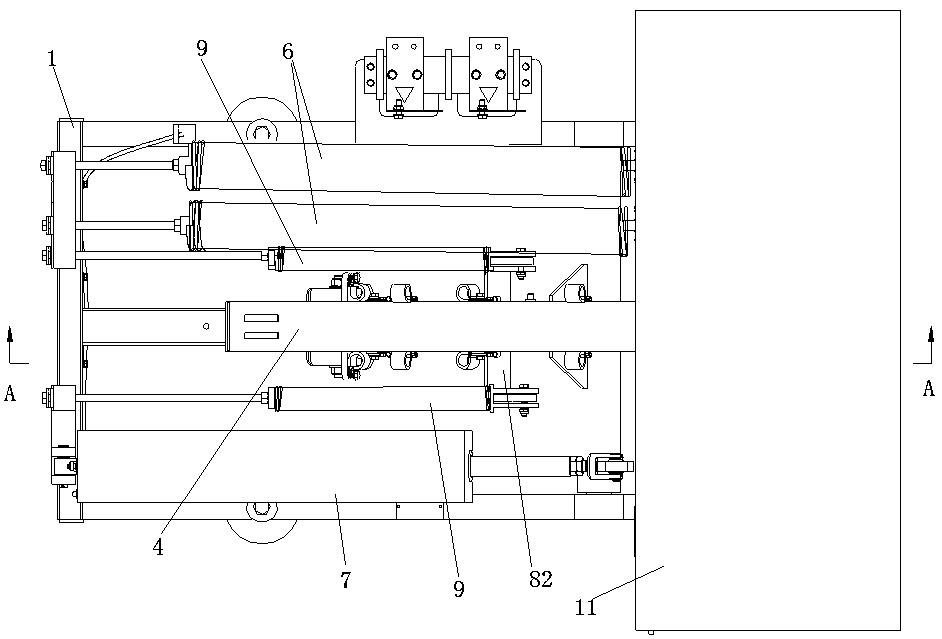

[0035] Such as Figure 1~4 As shown, a trolley bus power receiving system includes an underframe 1, a lower arm 3, an upper arm 4, a pull rod 5, a lifting bow drive device installed on the underframe 1, a bow charger 2, and a force transmission member 8 , balance spring 9.

[0036] The lower arm 3 is T-shaped, its cross bar is hinged with the underframe 1 , and the upper end of its vertical bar is hinged with the upper arm 4 . A plurality of ear plates 31 are fixedly arranged on the cross bar.

[0037] The lifting bow driving device is connected with the lower arm 3 and can drive the lower arm 3 to rotate around the hinge point between the lower arm 3 and the chassis 1 . The bow lifting device includes a bow lifting cylinder 7 and a bow lifting spring 6 . The bow raising cylinder 7 is installed on the underframe 1 . The piston rod of the bow-raising cylinder 7 is connected with the ear plate 31. One end of the lifting bow spring 6 is connected to the ear plate 31 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com