Multi-layer flow guiding composite bellows

A bellows and composite technology, applied in the field of bellows, can solve the problems of failure of bellows, failure to meet emission noise standards, noise, etc., to achieve the effect of extending service life, good sealing performance, and solving noise emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

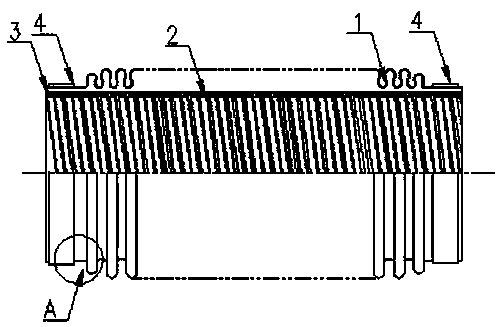

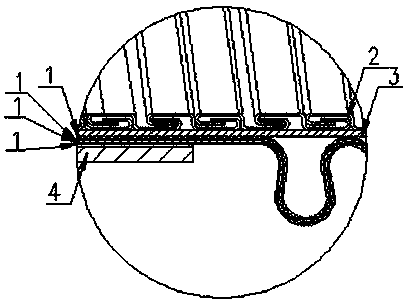

[0017] see figure 1 and 2 , a multi-layer guide composite bellows of the present invention, including a body, the body includes a bellows, a guide tube, a protection net and a reinforcement ring, the bellows adopts a 4-layer structure, and the guide tube is sleeved inside the bellows , the protection net is set on the outside of the bellows, the two ends of the bellows are provided with straight ends, and the reinforcing ring is set on the outside of the straight ends to connect the related parts by welding. The process is formed at one time.

[0018] The invention has good anti-fatigue effect, the production process adopts hydraulic molding, no air leakage, no water leakage, good sealing performance, and because the product has four layers, there is a certain isolation space between the layers, and the solid insulation performance is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com