Efficient automatic core aligning device for fiber fusion splicer

An optical fiber fusion splicer, high-efficiency technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of motion accuracy restriction, difficult to keep up, etc., to achieve the effect of improving the quality of optical fiber fusion, fast adjustment speed, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

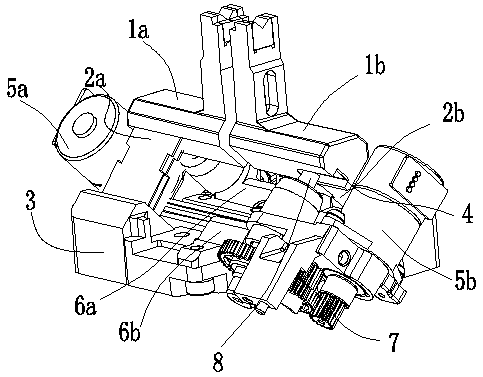

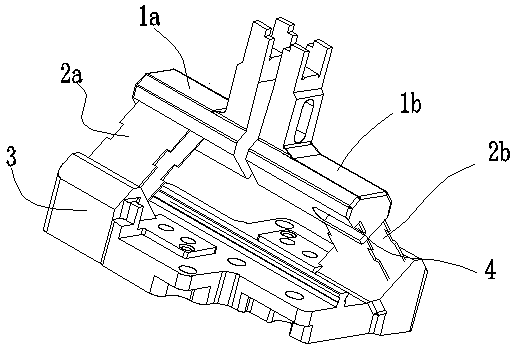

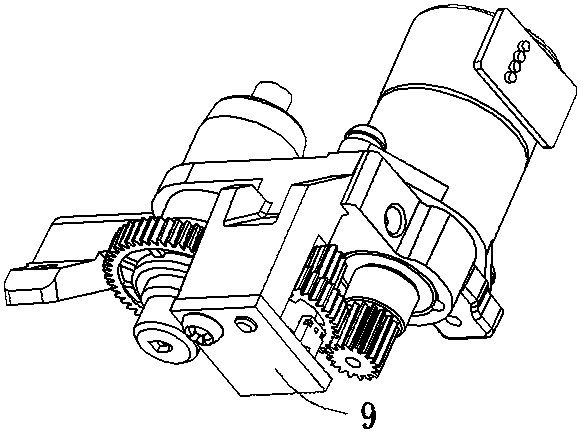

[0023] The high-efficiency automatic core alignment device of the optical fiber fusion splicer in this embodiment is as follows: figure 1 As shown, including aligning frame assembly and power assembly. The centering frame assembly is formed by the left and right centering frames 1a and 1b, which are fixedly connected to the centering frame base 3 via two left and right elastic supporting pieces 2a and 2b. The power assembly is installed on the centering frame assembly through screws, and its layout is also a pair of central symmetry, including the left motor 5a and the left connecting frame 6a, and the right motor 5b and the right connecting frame 6b, both of which are equipped with a gear mechanism 7 and a wire The rod mechanism 8 and the lead screw mechanism 8 are used to lift the centering frame. Since the centering frame and the base of the centering frame are connected by an elastic support piece, the elastic support piece is installed obliquely at 45°, and the output rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com