Practical liquid crystal display module

A liquid crystal display module and liquid crystal display panel technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of thermal expansion of the light guide plate, affecting the normal operation of the light bar, affecting the use effect and life of the liquid crystal display module, etc. Reach the requirements of reducing thermal conductivity, increase the range of selection, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

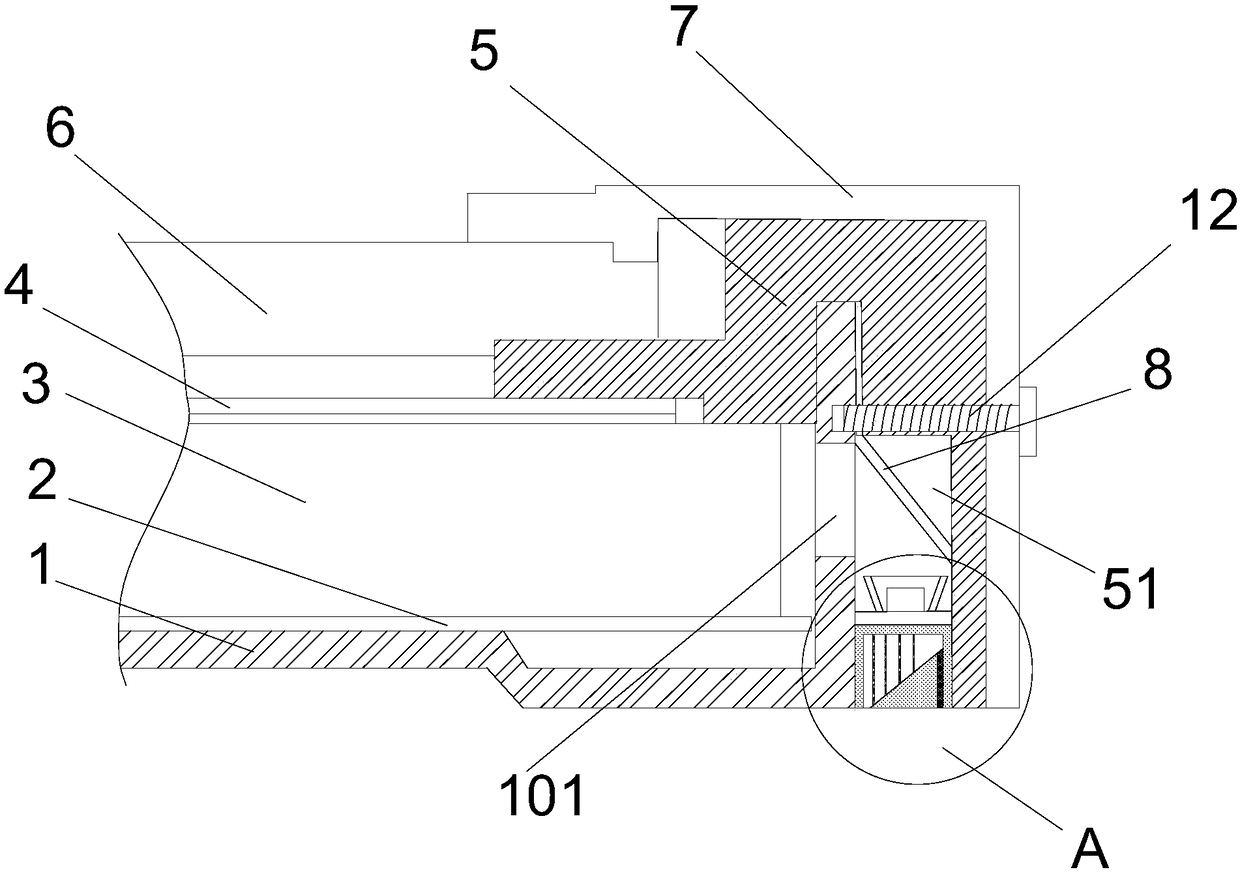

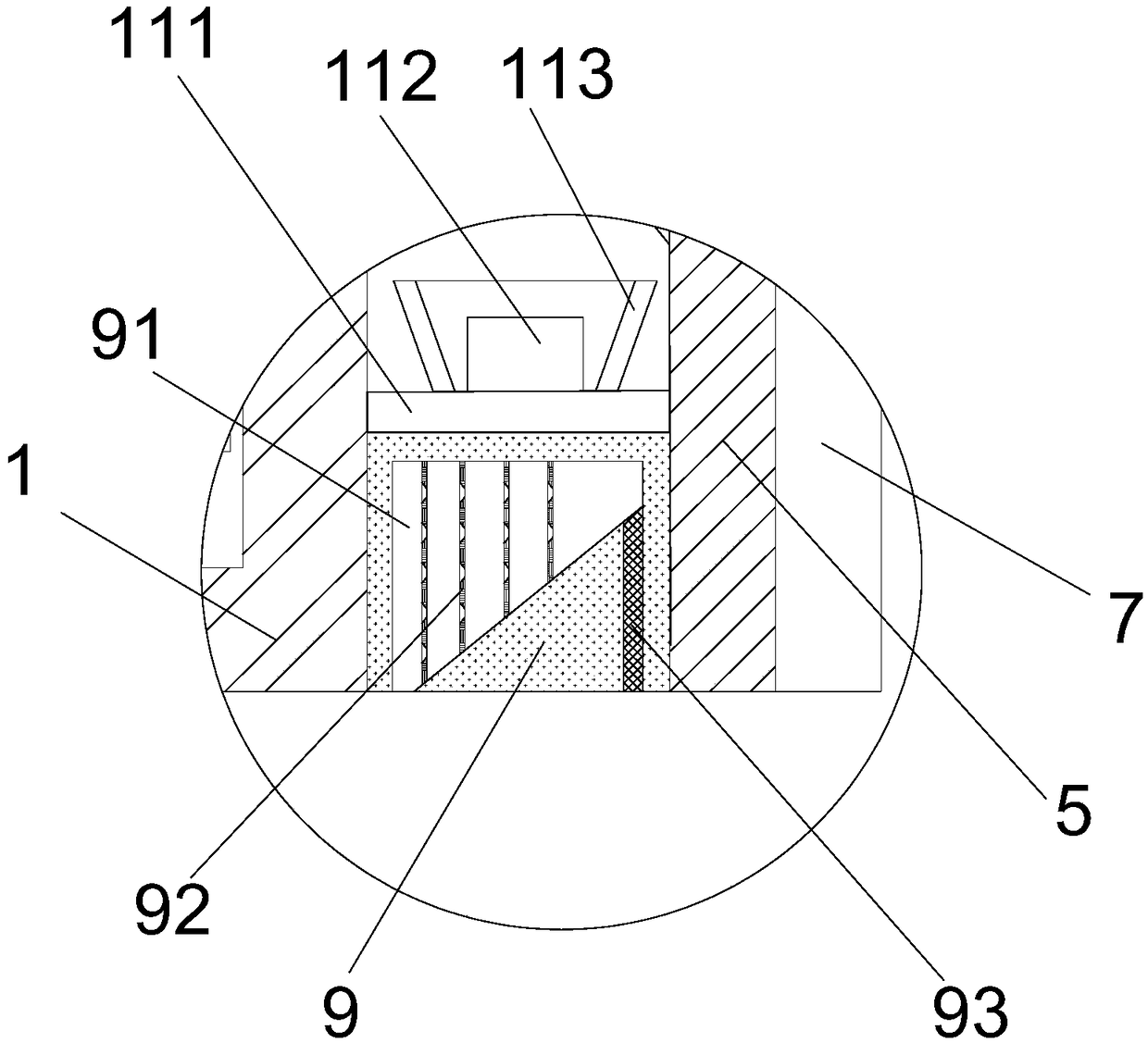

[0016] refer to figure 1 with figure 2 As shown, a practical liquid crystal display module proposed by the present invention includes a back plate 1, a reflective sheet 2, a light guide plate 3, an optical film material 4, a plastic frame 5, a liquid crystal display panel 6, an outer frame 7, and a reflective mirror 8 , cooling block 9 and LED light bar;

[0017] The reflective sheet 2 is installed on the backplane 1, the light guide plate 3 is installed on the top of the reflective sheet 2, the optical film material 4 is installed on the top of the light guide plate 3, the plastic frame 5 is set on the backplane 1, and the liquid crystal display panel 6 is installed on the plastic frame 5, and located above the optical film material 4, the outer frame 7 is sleeved on the plastic frame 5, a light guide through hole 101 is provided on the side of the back plate 1 corresponding to the position of the light guide plate 3, and the plastic frame 5 is located on the back plate An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com