Flexible job shop batch dynamic scheduling optimization method

A technology of flexible operation and optimization method, applied in the direction of electrical program control, comprehensive factory control, etc., can solve problems such as insufficient flexibility/intelligence, insufficient response time, and reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

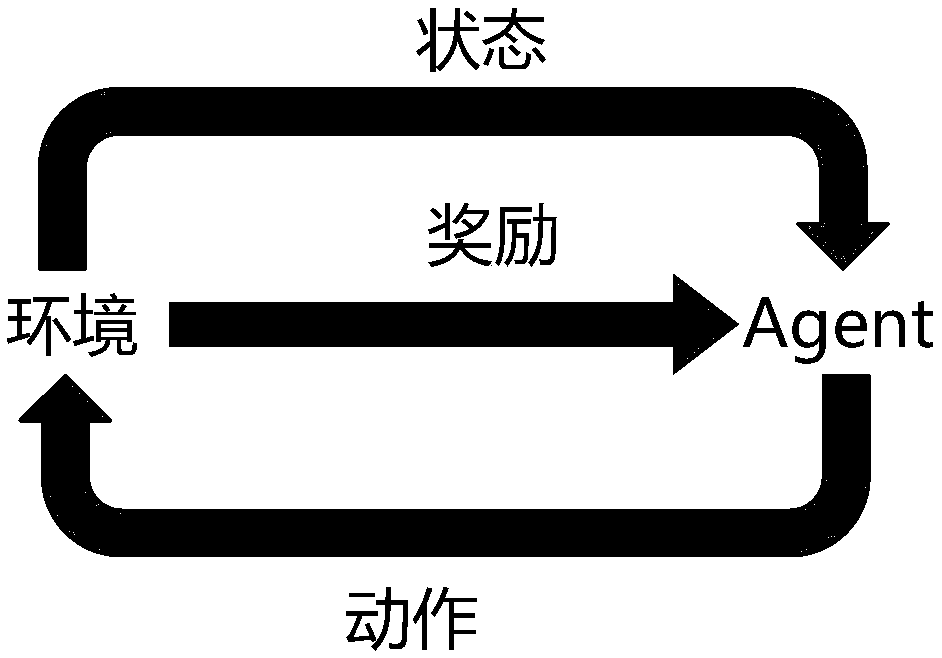

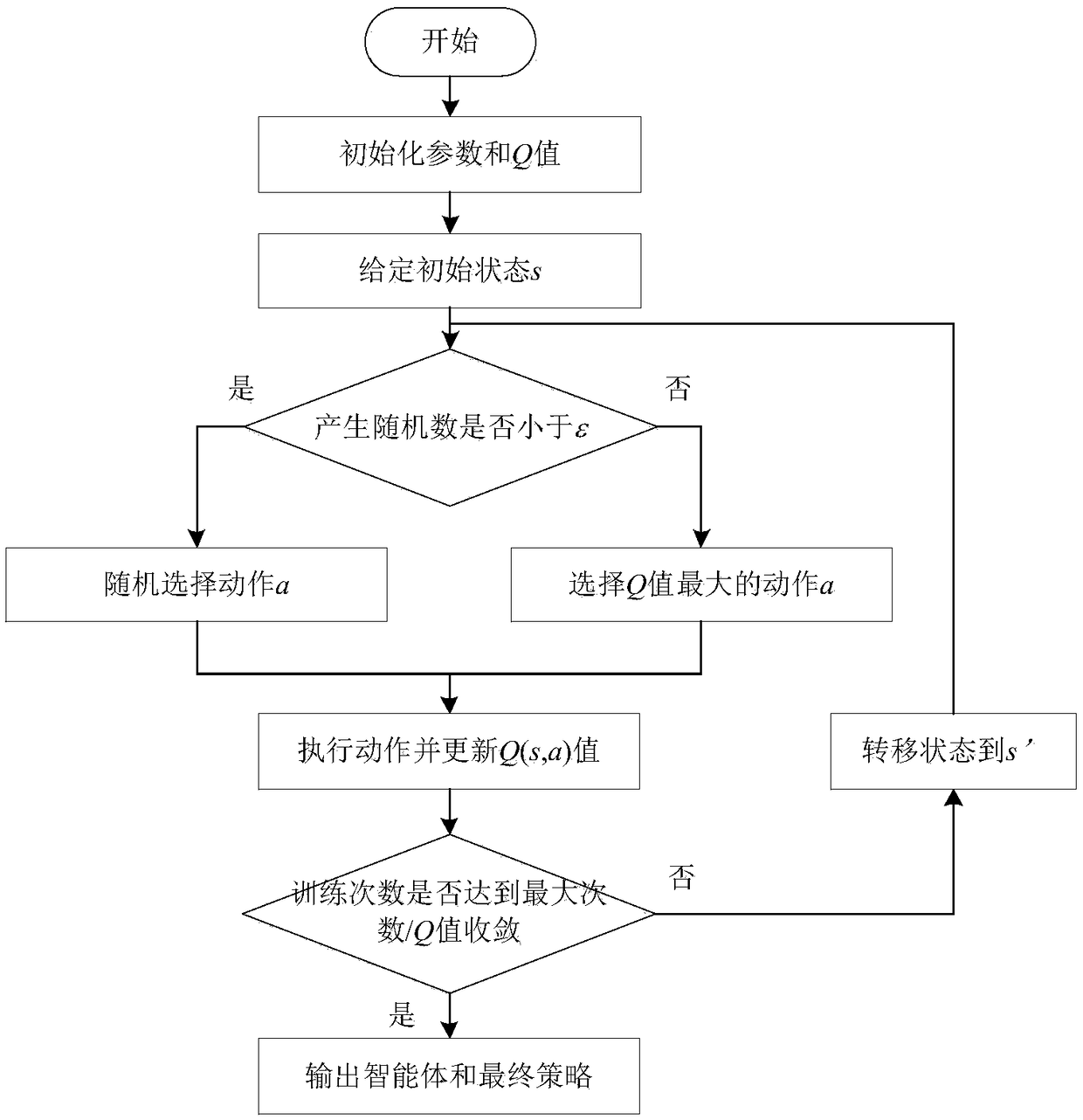

[0072] attached figure 1 Learn schematics for Q; figure 2 Learning flowchart for Q;

[0073] In the example used in this patent, the parameters in initializing Q-learning are learning rate α=0.5, discount factor γ=0.9, control factor a=0.01, and greedy search threshold ε=0.95.

[0074] 1. Single-process BDFJSP experiment

[0075] The artifact input required for this experiment is shown in Table 2, where each parameter satisfies the uniform distribution of the range in the table.

[0076] Table 2 Single-process BDFJSP input table

[0077]

[0078] where NOM is the number of workpieces processed on machine m

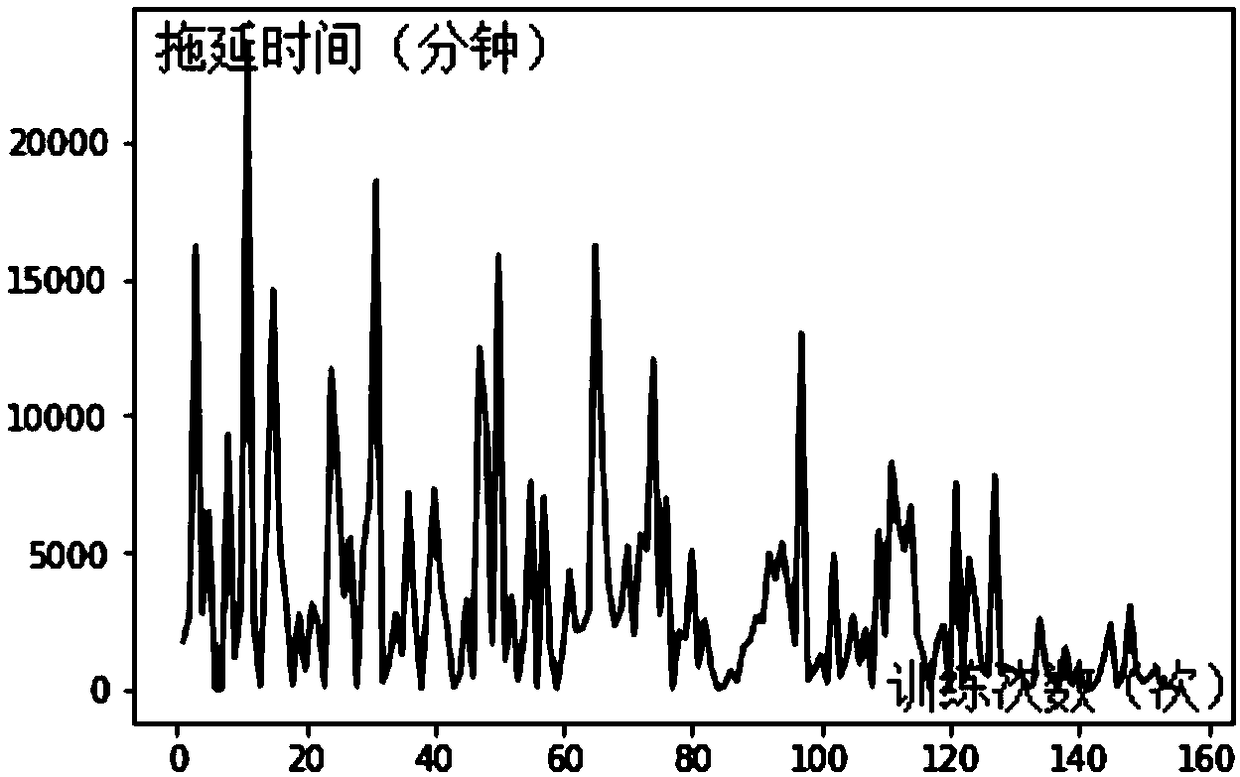

[0079] According to the input, the results obtained by using Q-learning and three priority rules to calculate 10 times respectively are shown in Table 2. The learning process graph and the distribution line graph of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com