A lockable high current pin jack assembly

A hole component, high current technology, applied to electrical components, components of connecting devices, circuits, etc., can solve problems such as long separation distance, large insertion force, small current load between jack and pin, and achieve contact The effect of large area and strong carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The lockable high-current pin socket assembly of the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

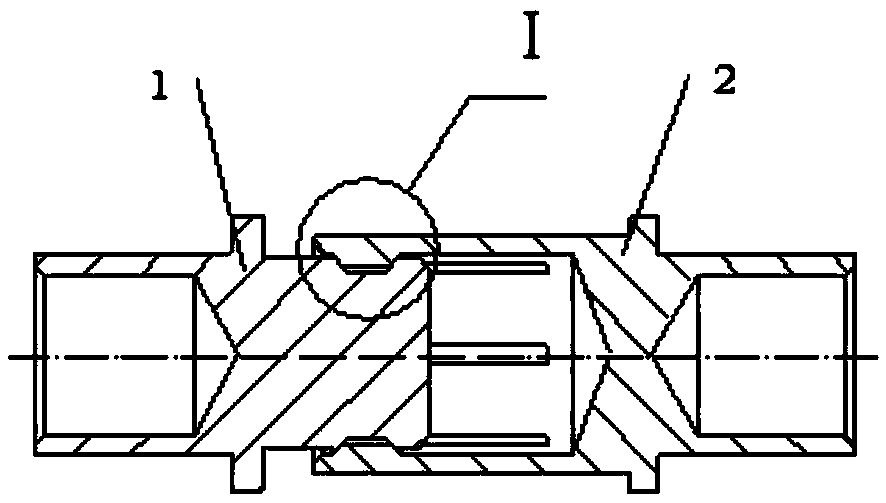

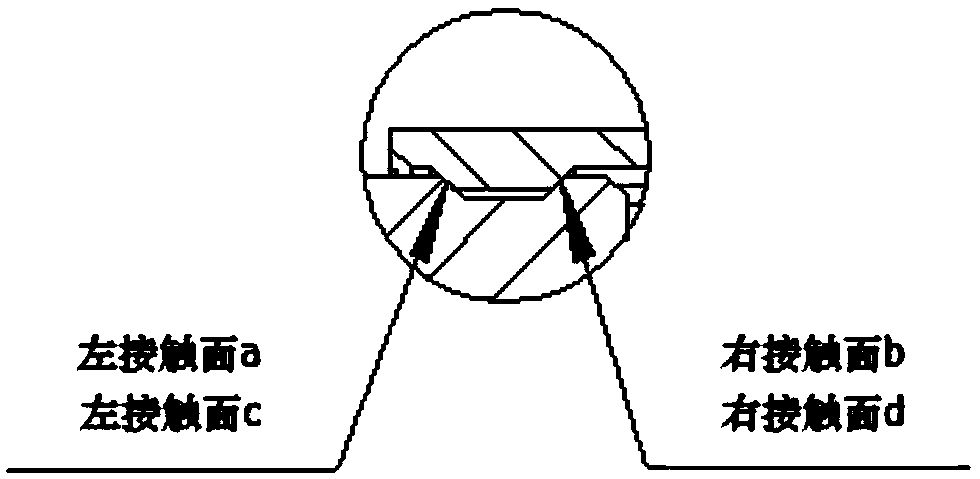

[0023] The lockable high-current pin socket assembly of the present invention includes a socket 1 with an annular protrusion and a socket 2 with an annular groove; the insertion end of the socket 3 has circumferentially evenly distributed Slotted into 6 petals, the inner hole of the insertion end of the jack 3 has an inward annular protrusion, and the annular protrusion has a left contact surface c and a right contact surface d; the pin 4 needle head is provided with An annular groove matched with the annular projection at the insertion end of the socket 3, the annular groove has a left contact surface a and a right contact surface b.

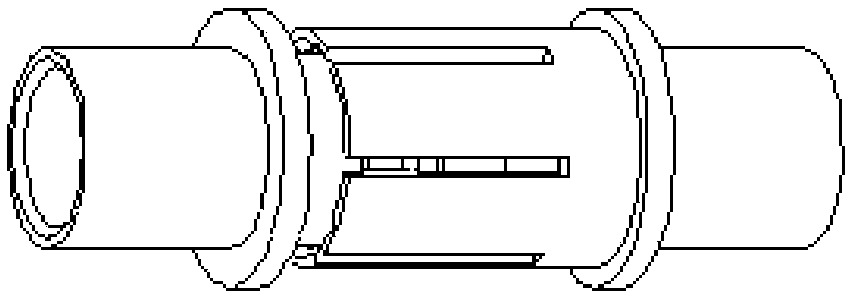

[0024] The assembly and combination diagram of the pin socket assembly of the present invention is as follows figure 1 As shown, the combined cross-sectional schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com