A kind of Antarctic krill shelling roller and using method thereof

An Antarctic krill and roller technology is applied in the field of Antarctic krill shelling rollers, which can solve the problems of high requirements for anti-rust and waterproof functions, increased equipment costs, severe vibration of equipment, etc., and reduces the requirements for anti-rust and waterproof functions. , The effect of reducing the impact of equipment operation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

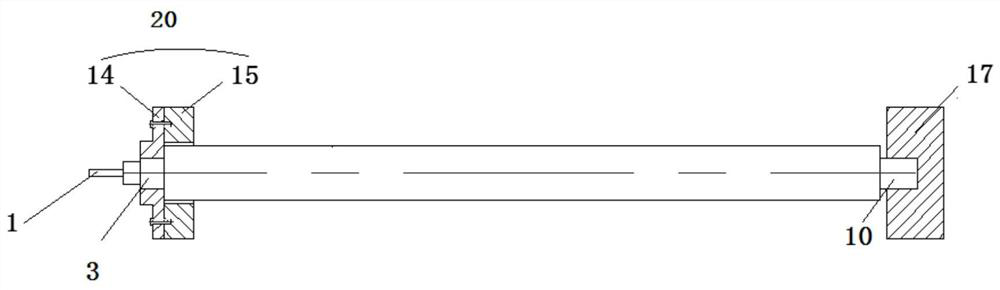

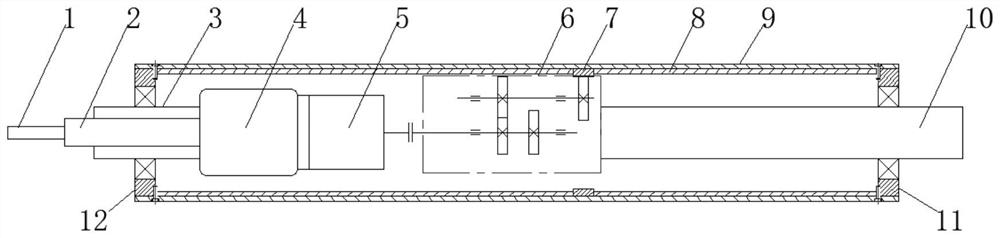

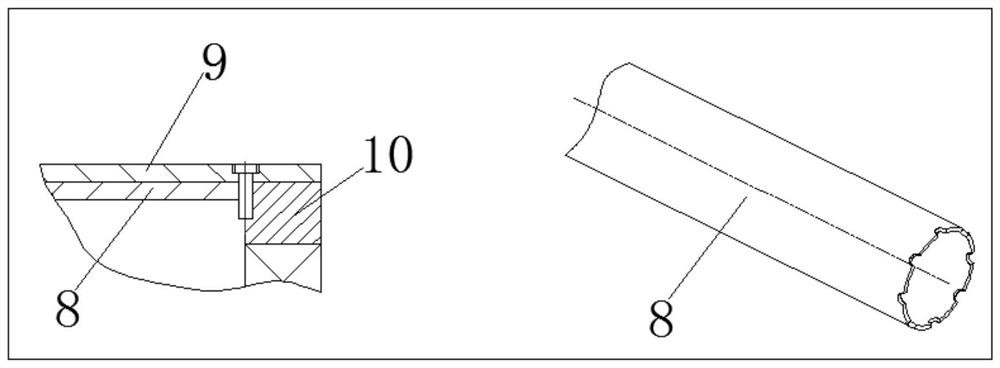

[0031] see Figure 1-5 , Each roller assembly in the Antarctic krill shelling roller device is independently juxtaposed in the shelling machine frame, and the reciprocating rotation of the outer ring of the roller can be realized after one end of the connecting line of each roller assembly is connected to the control circuit. The connection lines of each independent roller assembly are finally connected to the main control cabinet, which is independent of the shelling machine device, and the space is arranged freely, which saves the site occupied space, and also facilitates the protection of electrical components and enhances the service life of the equipment.

[0032] like figure 1 As shown, in order to allow quick replacement of each roller assembly, the roller assembly can be disposed of from the front bearing seat into the Antarctic krill sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com