Three-dimensional curvature pipe bending machine and using method thereof

A three-dimensional curvature, pipe bending machine technology, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problem of excessive waste of pipe material, and achieve simple and convenient installation, reduce production costs, and reduce excess material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

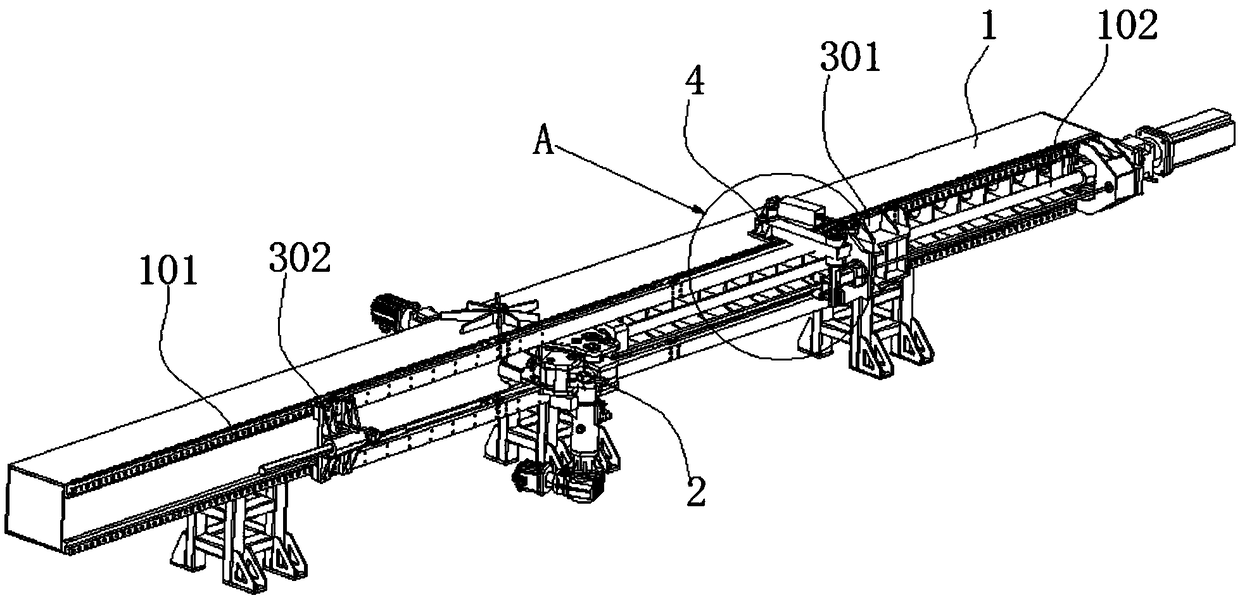

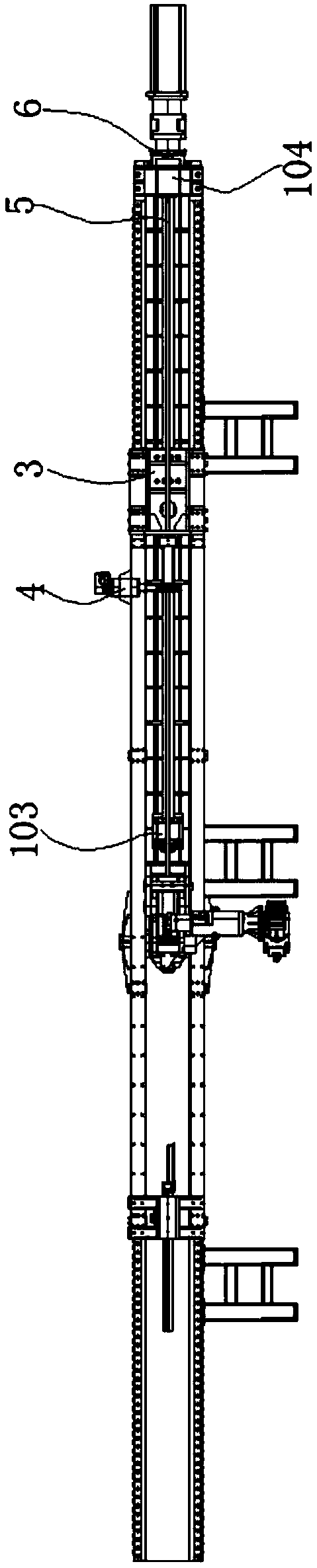

[0054] Such as figure 1 and image 3 As shown, a three-dimensional curvature pipe bending machine includes a frame 1, and the frame 1 is used as a supporting platform, and a pipe bending device 2 and a feeding device 3 are connected to one side of the frame, and the feeding device 3 includes a synchronously moving pushing mechanism 301 and a top The material mechanism 302, the pipe bending device 2 is located between the material pushing mechanism 301 and the material pushing mechanism 302, the material pushing mechanism 301 is used to push the pipe to move, and the material pushing mechanism 302 is used to tighten the pipe until the end of the pipe is in contact with the material pushing mechanism 301 are in close contact with each other, and the function of the ejector mechanism 302 can also be realized in other ways, such as using manual hand pushing. The design of the ejector mechanism 302 improves the automation productivity, saves manpower, and is also conducive to the s...

Embodiment 2

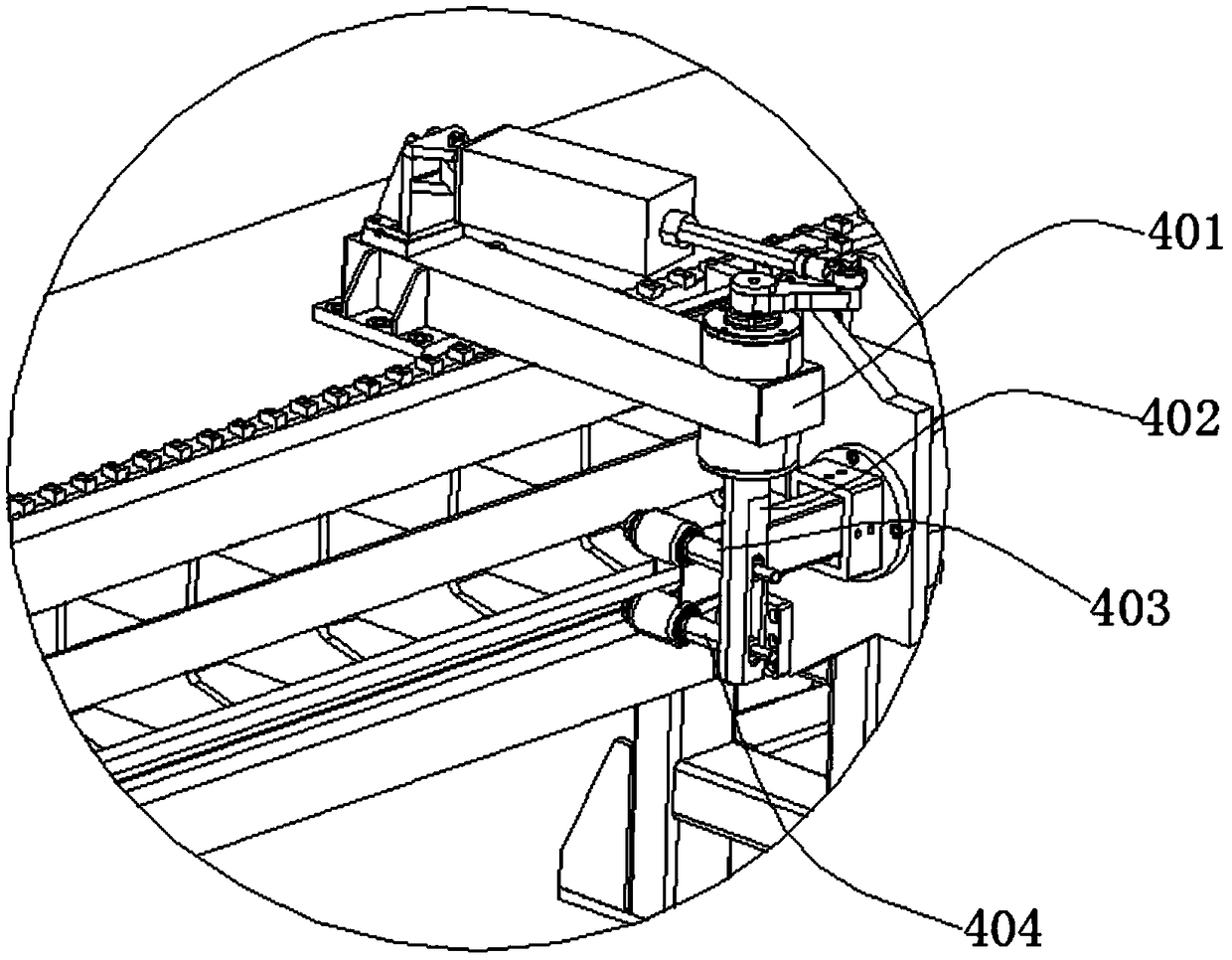

[0058] With embodiment 1, difference is: as figure 2 As shown, the auxiliary device 4 is also included, the auxiliary device 4 includes a support base 401, a vertical bar 402, an upper auxiliary bar 403 and a lower auxiliary bar 404, the support base 401 is fixed on the top of the frame 1, and the end extends out of the frame 1 the left side; the top of the vertical bar 402 is rotatably connected to the end of the support base 401, and the bottom is connected with the upper auxiliary bar 403 and the lower auxiliary bar 404; the upper auxiliary bar 403 and the lower auxiliary bar 404 are arranged in parallel, and the upper auxiliary bar 403 and the lower auxiliary bar 403 Auxiliary rod 404 is used to clamp the pipe. The top of the vertical bar 402 protrudes from the support base 401 and is connected with a cross bar. The support base 401 is provided with a driving device for pushing or pulling the other end of the cross bar. The auxiliary mechanism in this embodiment can cont...

Embodiment 3

[0061]Same as Embodiment 1, the difference is that the pipe bending device 2 includes a fixed seat 201, a pipe channel, a first fixed guide wheel 203, a first drive part 204, a second drive part 205, a second fixed guide wheel 207, a third Fixed guide wheel 208, first bending wheel 209, second bending wheel 210 and block 211; Fixed base 201 is installed on the side of frame 1 as the supporting platform of pipe bending device 2, and fixed base 201 comprises top cover and Bottom cover; the first fixed guide wheel 203, the pipe channel, the second fixed guide wheel 207, the third fixed guide wheel 208 and the stopper 211 are located between the top cover and the bottom cover, the first fixed guide wheel 203 and the second fixed guide wheel The wheel 207 is located on one side of the pipe passage, the third fixed guide wheel 208 and the stopper 211 are located on the other side of the pipe passage; the first bending wheel 209 is located at the outlet of the pipe passage, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com