Integral Extrusion Die for Complicated Inner Ring Rib of Light Alloy Shell

A technology of extrusion forming and light alloy, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high processing and assembly requirements of support structure molds, material loss and difficulty in accurate realization, etc., and achieve simplification Difficulty in mold design, assembly, and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

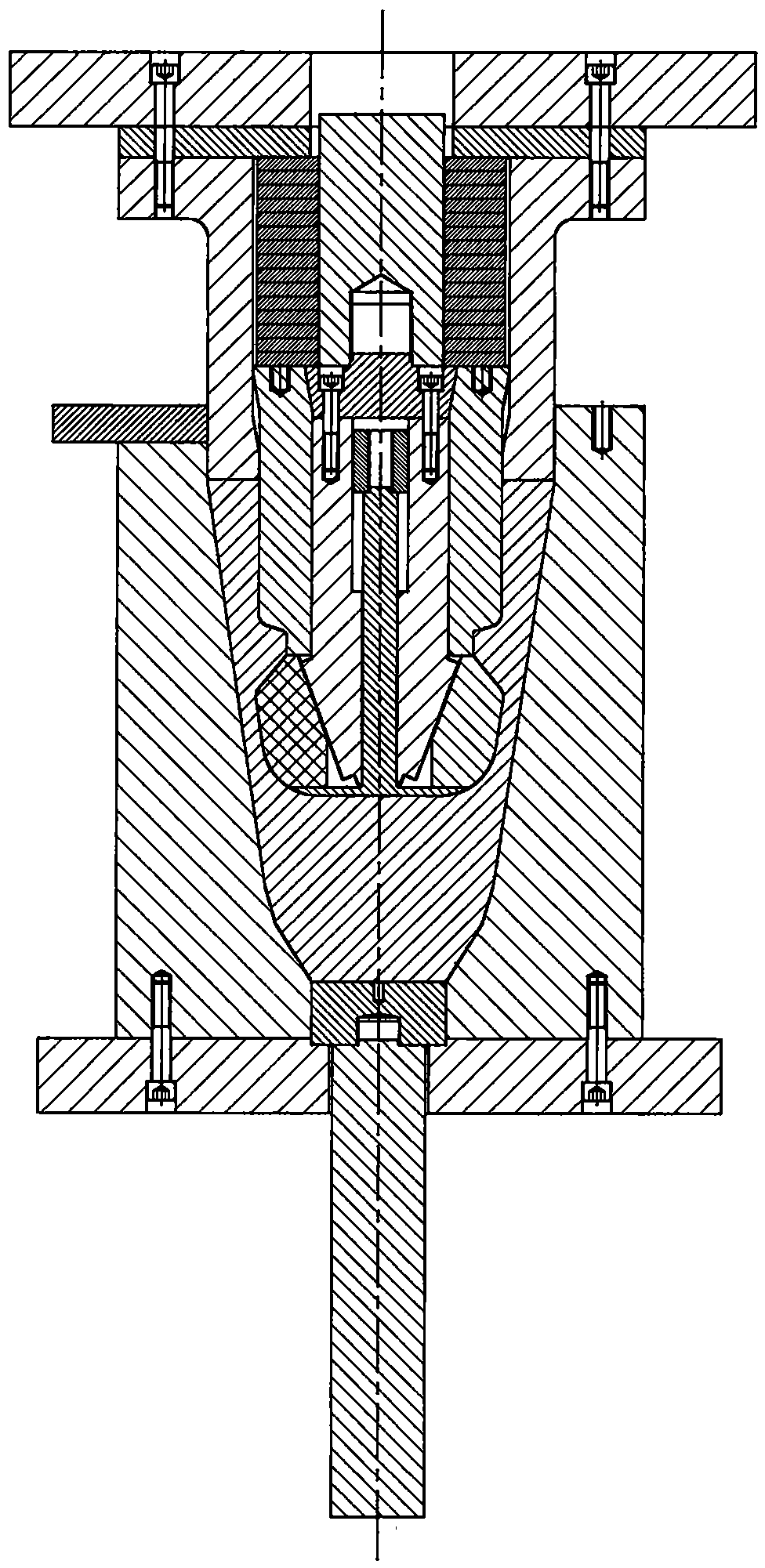

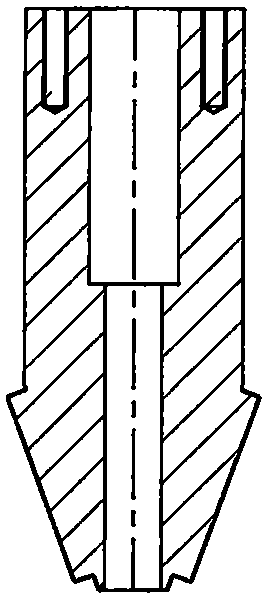

[0025] The invention discloses an integral extrusion forming die for a complex inner ring rib of a light alloy shell, such as Figure 1-4 As shown, it includes an upper die assembly connected to the upper structure of the press, an inner support structure assembly, and a lower die assembly connected to the lower structure of the press. The die assembly includes a punch 4 that extrudes the light alloy barrel 17 downward.

[0026] The upper die assembly also includes an upper die plate 1 and an upper die pad 2 connected to the upper worktable of the press. The upper template 1 is assembled on the upper workbench of the press with fastening bolts. The upper die plate 1 , the upper die pad 2 and the punch 4 are assembled together by hexagon socket head cap screws 3 .

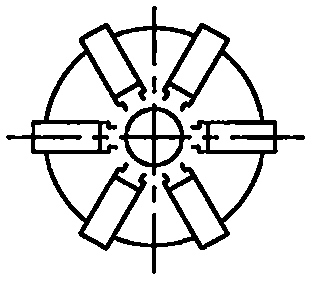

[0027]The inner support structure assembly includes a disc spring 5 , a disc spring support rod 6 , a wedge 7 , an upper inner support 8 , a mandrel 9 and a lower flexible filler inner support 10 . The wedge 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com