Batch automatic laser printing system for transformer shells

A laser printing and transformer technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of labor consumption and low work efficiency, and achieve the effect of preventing material drop and improving the efficiency of marking work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

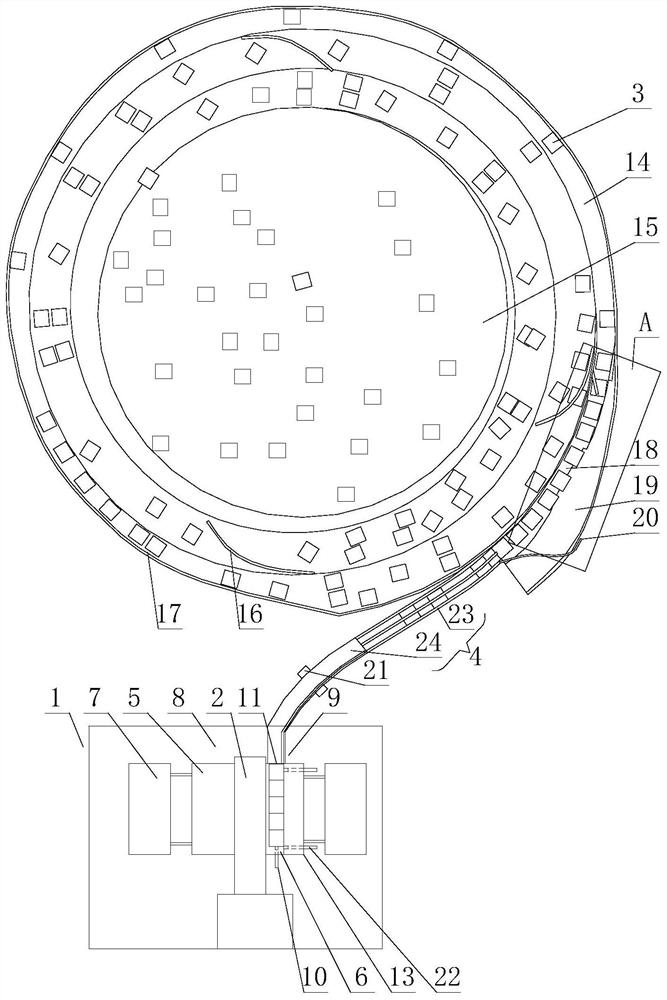

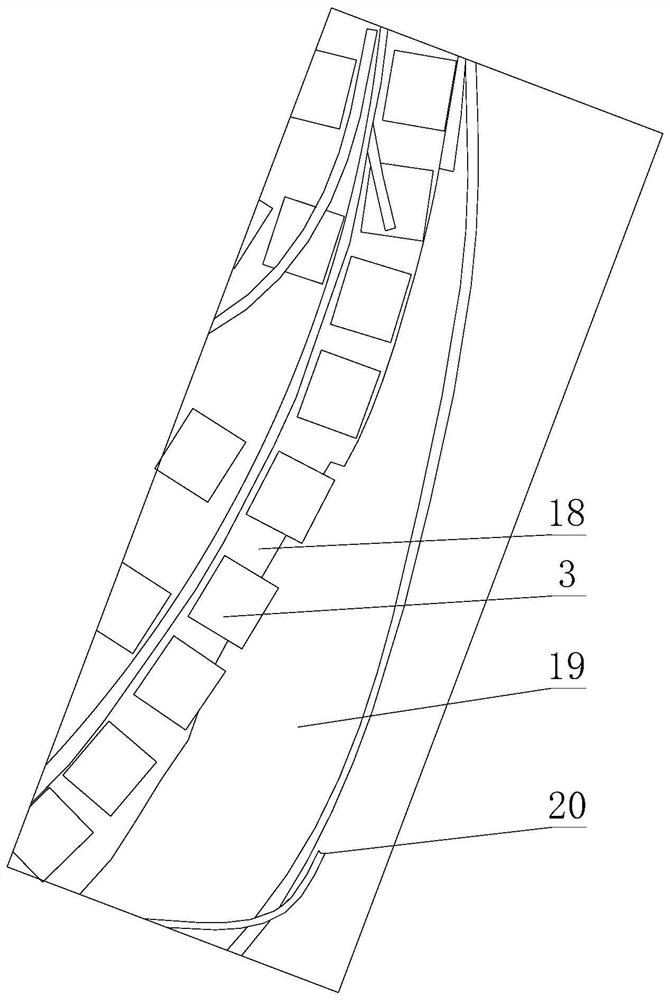

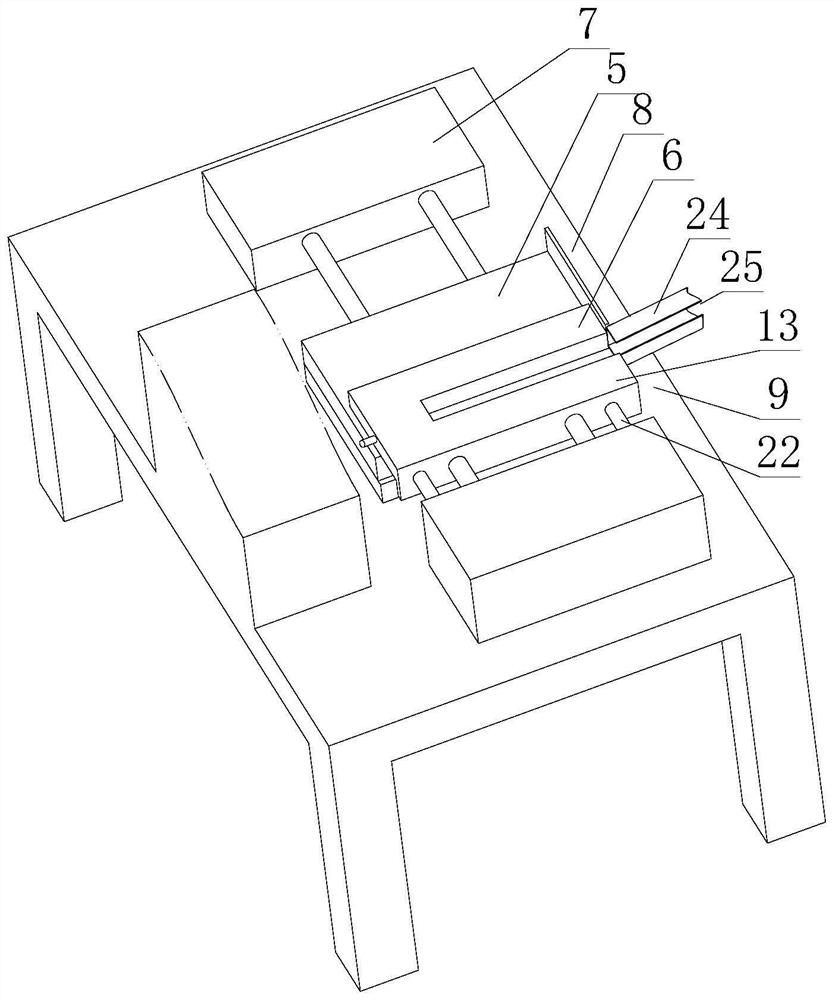

[0020] The batch automatic laser printing system for transformer shells includes a feeding station and a printing station. The printing station includes a laser printer 2 with a workbench 1. The key point is that the feeding station includes a The automatic sorting feeding unit of the device housing 3 and the feeding channel 4 connected to the output end of the automatic sorting feeding unit, the workbench 1 is provided with a tray 5 and a housing arrangement frame 6 arranged on the tray 5 And the telescopic mechanism 7 that is connected with the tray 5 and the housing arrangement frame 6 respectively, the workbench 1 is divided into the printing area 8 set adjacently and the retrieving area 9 where the discharge port of the feeding channel 4 is located, the tray 5 and the housing are arranged The frame 6 has the degree of freedom to reciprocate in the printing area 8 and the feeding area 9 respectively by means of the telescopic mechanism 7. The two ends of the shell arrangeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com