Welding equipment for heat collecting copper pipes of wall-mounted solar water heater

A technology of solar water heaters and welding equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding efficiency, loss of working time, and consumption of floor area, so as to improve work efficiency and operation Simple, fast, and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

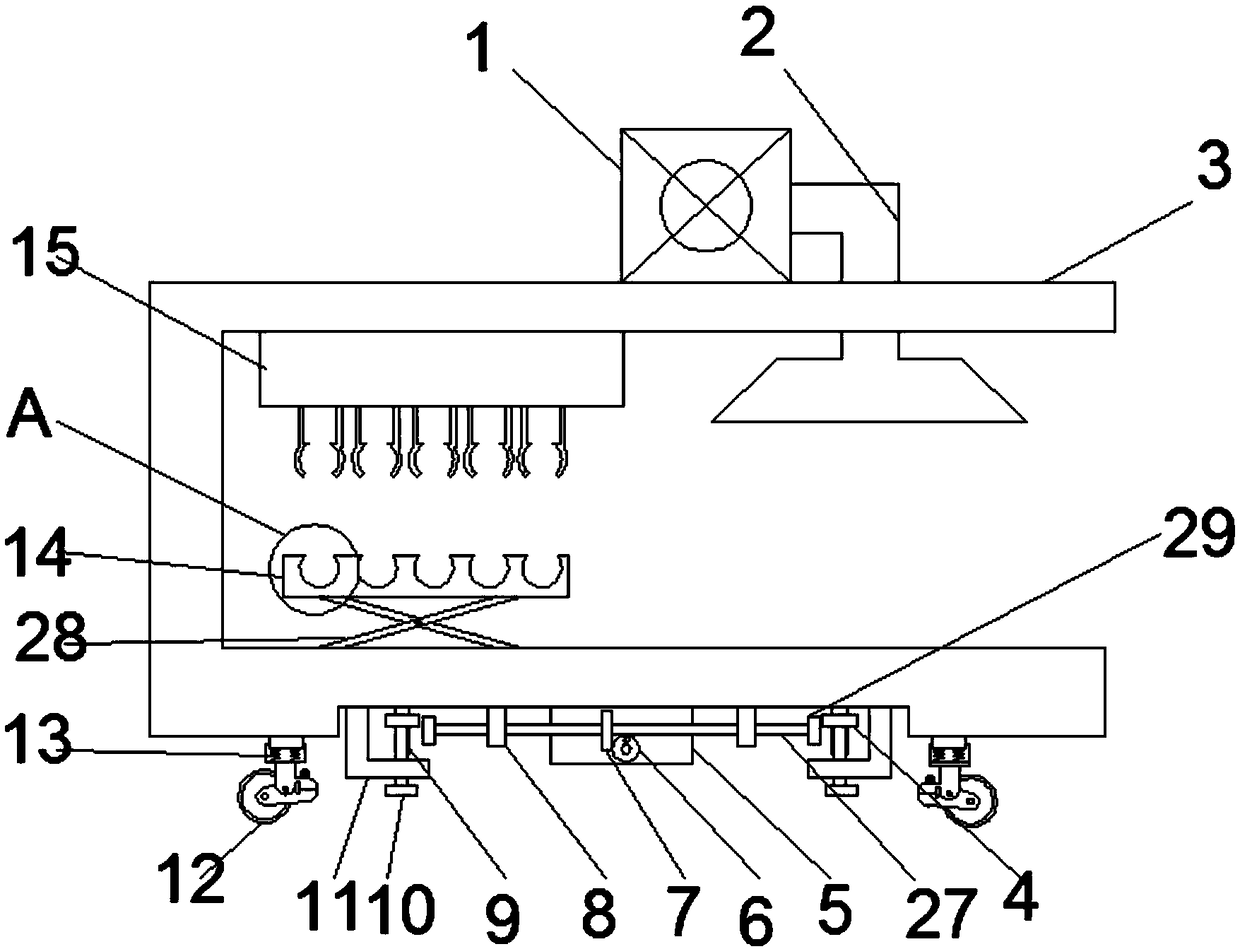

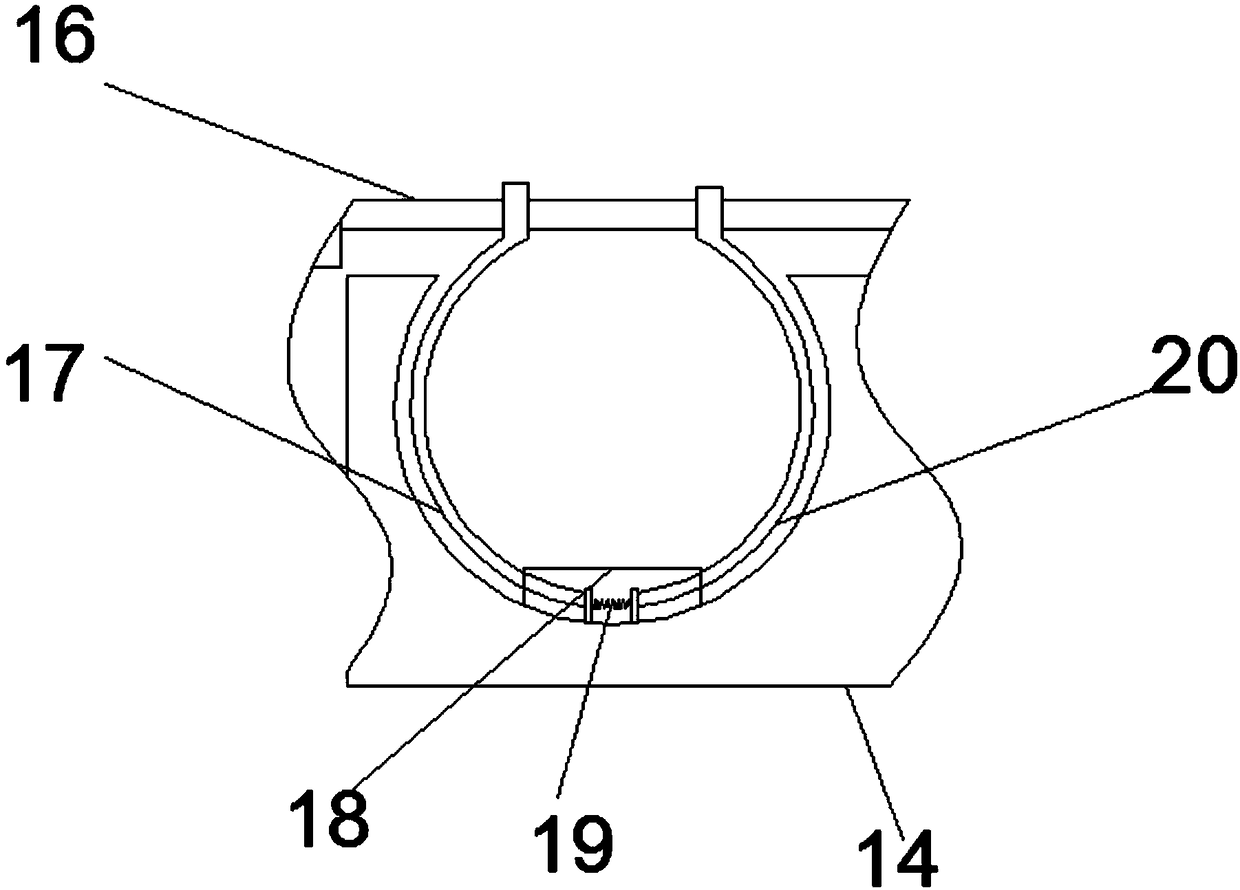

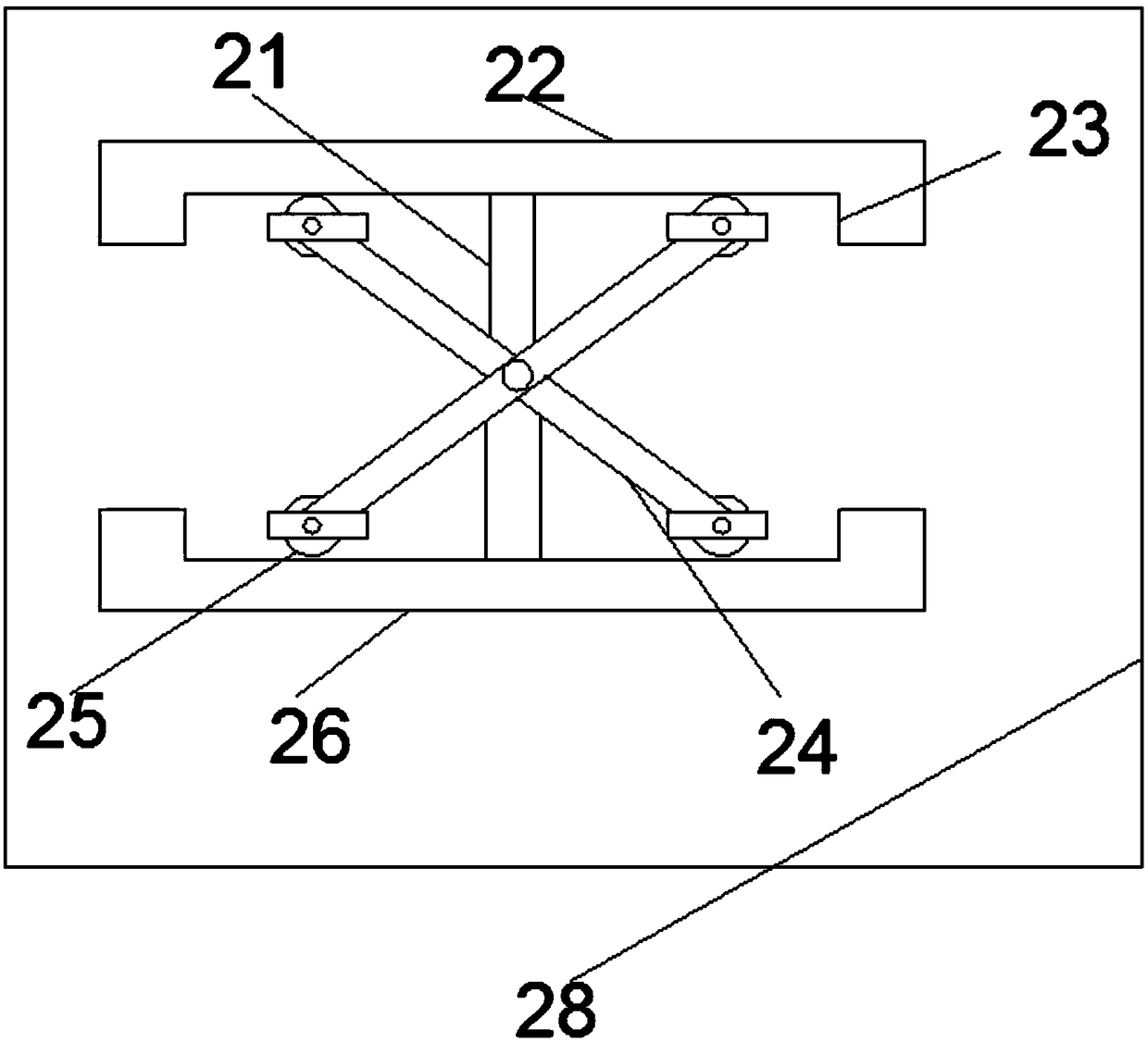

[0018] like Figure 1-Figure 3 As shown, a kind of wall-mounted solar water heater thermal collector copper tube welding equipment proposed by the present invention includes a bracket 3, a plurality of universal wheels 12 are arranged at the lower end of the bracket 3, a first spring 13 is arranged inside the universal wheel 12, and the bottom of the bracket 3 is arranged There is a depression, the gear box 5 is set in the middle of the depression, the left and right sides of the gear box are equipped with fixed blocks 8, the inside of the gear box 5 is penetrated with a connecting rod 27, and the connecting rod 23 runs through the fixed block 8, and the middle position of the connecting rod 27 is set There is a first bevel gear 7, the right side of the first bevel gear 7 meshes with the second gear 6, the second gear 6 is connected to the gear box 5 in rotation, the left and right ends of the connecting rod 27 are provided with a second bevel gear 29, two second bevel gears B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com