A soft porcelain product cooling device

A cooling device and product technology, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of poor cooling effect and poor performance of soft porcelain products, and achieve high reliability, good cooling effect, and soft porcelain products. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

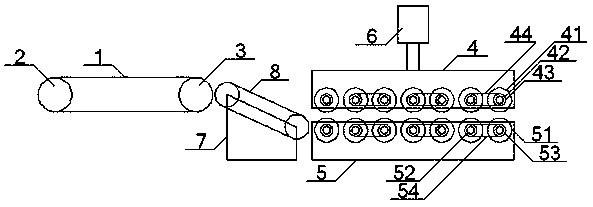

[0042] see figure 1 , a cooling device for soft porcelain products, comprising a No. 1 conveyor belt 1 and a cooling box, one end of the No. 1 conveyor belt 1 is provided with a No. 1 pulley 2, and the No. 1 pulley 2 is driven by a No. 1 belt and a No. 1 motor connection, the other end of the inner side of the No. 1 conveyor belt 1 is provided with a No. 2 pulley 3, and the cooling box includes an upper case 4 and a lower case 5 arranged symmetrically; The No. 1 cooling pipe 41 arranged horizontally, the two ends of the No. 1 cooling pipe 41 are all installed on the inner wall of the upper housing 4 through the No. 1 bearing 42, and the two ends of the No. 1 cooling pipe 41 are equipped with a No. 1 pulley 43, adjacent The No. 1 pulley 43 on the two No. 1 cooling pipes 41 is connected by the No. 2 belt 44 transmission, and the No. 1 pulley 43 on the No. 1 cooling pipe 41 close to the No. 1 conveyor belt 1 among the plurality of No. 1 cooling pipes 41 passes through The No. 3 ...

Embodiment 2

[0044] Basic content is the same as embodiment 1, the difference is:

[0045] see figure 1 , the outer wall of the upper casing 4 is vertically connected with a cylinder 6, and the upper casing 4 and the lower casing 5 are vertically connected with a No. No. 2 top cones are vertically connected around the opposite end faces, and the No. 2 top cones are arranged symmetrically with the No. 1 top cones.

Embodiment 3

[0047] Basic content is the same as embodiment 1, the difference is:

[0048] see figure 1 , a support 7 is arranged between the No. 1 conveyor belt 1 and the cooling box, and the support 7 is a right-angled trapezoidal structure. The oblique waist of the support 7 is provided with a No. 2 conveyor belt 8; the oblique waist of the support 7 is located on the second The positions on both sides of the conveyor belt 8 are provided with baffles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com