Method for predicting temperature of furnace core dead stock column of ironmaking blast furnace based on multi-element linear regression algorithm

A multiple linear regression, iron-making blast furnace technology, applied in blast furnace, blast furnace details, steel manufacturing process and other directions, can solve problems such as poor adaptability, dependence on experience, inefficient calculation of furnace core dead column temperature, etc., to achieve calculation speed Fast, high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

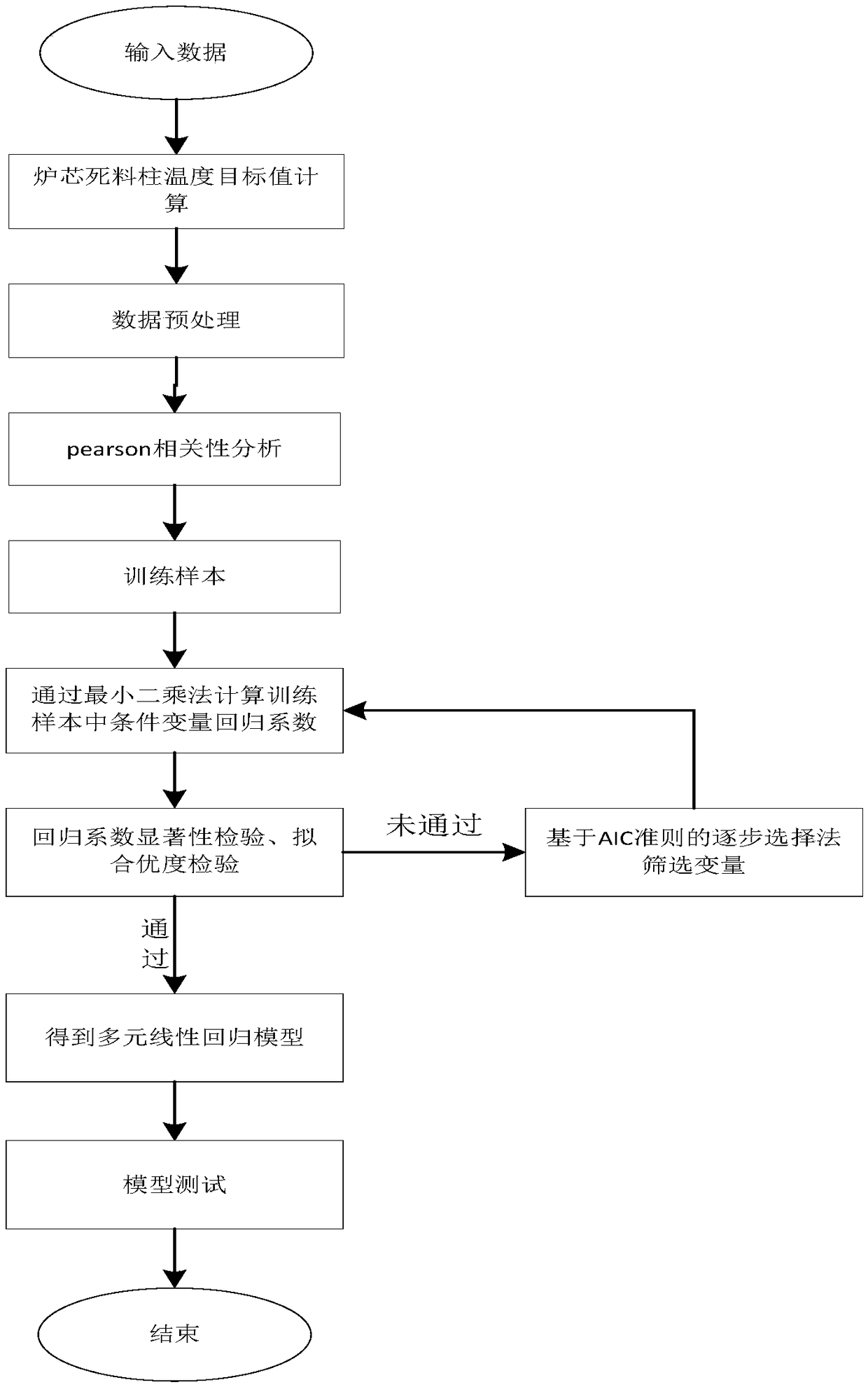

[0057] Combine figure 1 In this embodiment, a method for predicting the temperature of the dead material column of an iron-making blast furnace core based on a multiple linear regression algorithm, the steps of predicting the temperature of the hearth and core are as follows:

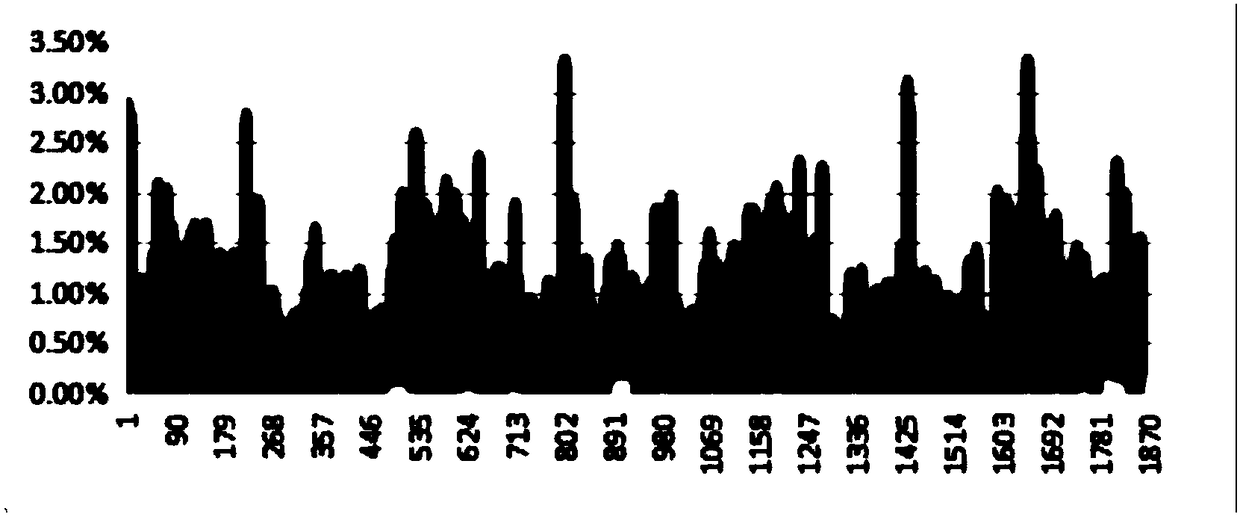

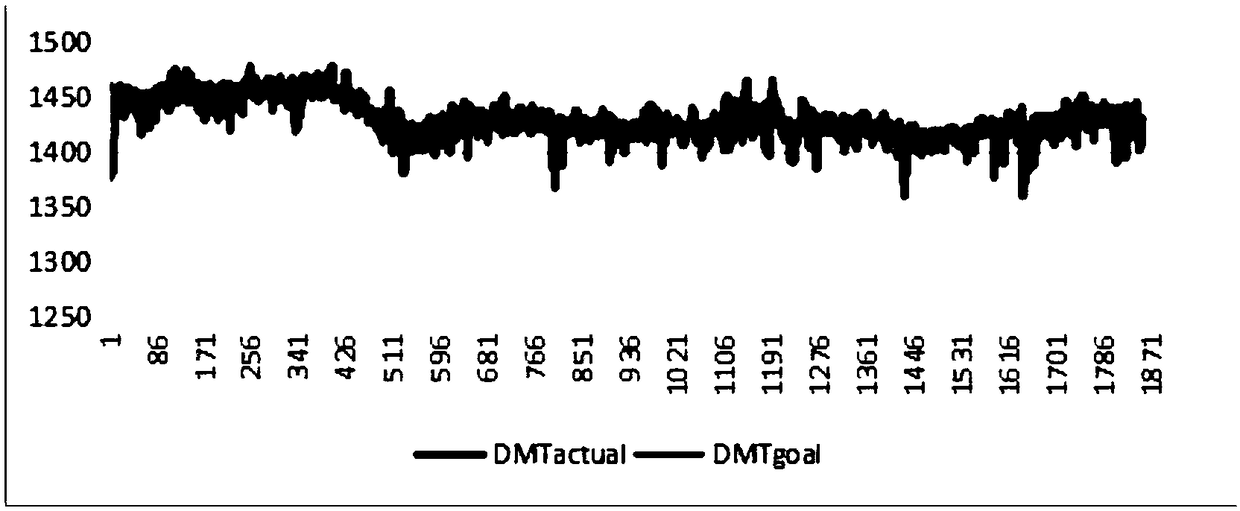

[0058] 1) Perform the target value of the furnace core dead material column temperature DMT on the collected data goal According to calculations, the data source of this embodiment is the missing operating parameter data obtained by the ironworks collecting operating parameters every hour from October 19, 2017 to January 18, 2018. The collected data of the dead material column temperature prediction is shown in Table 1.

[0059] Because it is very complicated to calculate the target value directly through the published estimation formula, it often needs to be obtained through multiple iterations of multiple variables. In order to simplify the calculation process, the calculation of the target value of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com