Dyeing and finishing process of polyester hole four-sided stretch cloth

A four-way elastic and polyester technology, applied in the field of fabric dyeing and finishing, can solve the problems of difficult control of the production process, complex production process and high production cost, and achieve the effect of maintaining aesthetics, soft and natural holes, and smooth fabric surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

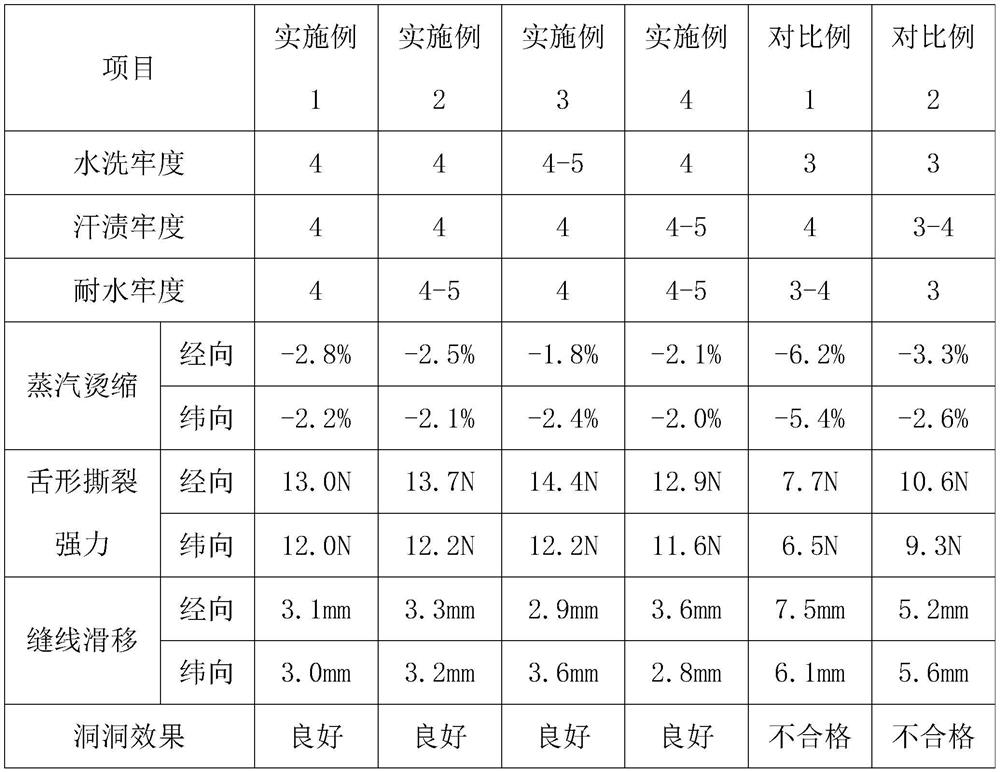

Examples

Embodiment 1

[0019] This embodiment provides a dyeing and finishing process of polyester hole four-sided stretch cloth, which specifically includes the following steps: unwinding - preshrinking - cold stacking - desizing - blank setting - in-cylinder desizing - in-cylinder dyeing - dehydration and opening - setting - Reel packaging.

[0020] In the pre-shrinking step, pre-wet with warm water at 60°C to 65°C for initial shrinkage and then put on the drying cylinder. The speed of the machine is 65m / min, and the pressure of the tension rod is 1.5kg / cm 2 , the roll pressure is 1.5kg / cm 2 , the temperature of drying cylinder 1#, 2#, 3#, 4#, 5#, 6#, 7#, 8#, 9#, 10#, 11#, 12#, 13#, 14# are respectively set as (100±5)℃, (100±5)℃, (105±5)℃, (105±5)℃, (110±5)℃, (110±5)℃, (120±5)℃, ( 120±5)℃, (120±5)℃, (120±5)℃, (130±5)℃, (130±5)℃, (130±5)℃, (130±5)℃.

[0021] The cold pile step is carried out in a cold pile machine with a first heating tank and a second heating tank, the temperature of the first ...

Embodiment 2

[0028] This embodiment provides a dyeing and finishing process of polyester hole four-sided stretch cloth, which specifically includes the following steps: unwinding - preshrinking - cold stacking - desizing - blank setting - in-cylinder desizing - in-cylinder dyeing - dehydration and opening - setting - Reel packaging.

[0029] In the pre-shrinking step, pre-wet with warm water at 60°C to 65°C for initial shrinkage and then put on the drying cylinder. The speed of the machine is 70m / min, and the pressure of the tension rod is 1.5kg / cm 2 , the roll pressure is 1.5kg / cm 2 , the temperature of drying cylinder 1#, 2#, 3#, 4#, 5#, 6#, 7#, 8#, 9#, 10#, 11#, 12#, 13#, 14# are respectively set as (100±5)℃, (100±5)℃, (105±5)℃, (105±5)℃, (110±5)℃, (110±5)℃, (120±5)℃, ( 120±5)℃, (120±5)℃, (120±5)℃, (130±5)℃, (130±5)℃, (130±5)℃, (130±5)℃.

[0030] The cold pile step is carried out in a cold pile machine with a first heating tank and a second heating tank, the temperature of the first ...

Embodiment 3

[0037] This embodiment provides a dyeing and finishing process of polyester hole four-sided stretch cloth, which specifically includes the following steps: unwinding - preshrinking - cold stacking - desizing - blank setting - in-cylinder desizing - in-cylinder dyeing - dehydration and opening - setting - Reel packaging.

[0038] In the pre-shrinking step, pre-wet with warm water at 60°C to 65°C for initial shrinkage and then put on the drying cylinder. The speed of the machine is 68m / min, and the pressure of the tension rod is 2.0kg / cm 2 , the roll pressure is 2.0kg / cm 2 , the temperature of drying cylinder 1#, 2#, 3#, 4#, 5#, 6#, 7#, 8#, 9#, 10#, 11#, 12#, 13#, 14# are respectively set as (100±5)℃, (100±5)℃, (105±5)℃, (105±5)℃, (110±5)℃, (110±5)℃, (120±5)℃, ( 120±5)℃, (120±5)℃, (120±5)℃, (130±5)℃, (130±5)℃, (130±5)℃, (130±5)℃.

[0039] The cold pile step is carried out in a cold pile machine with a first heating tank and a second heating tank, the temperature of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com