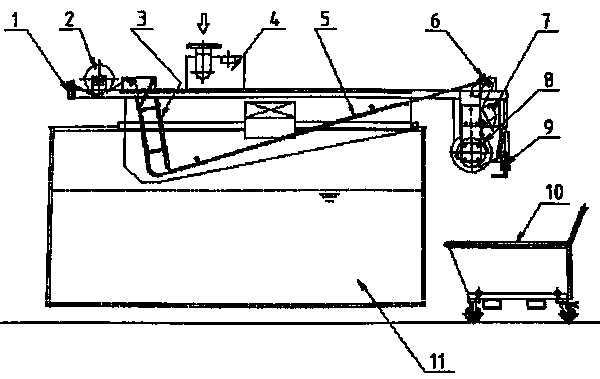

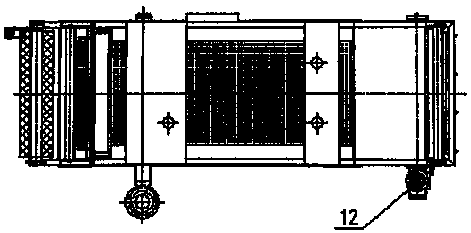

Novel paper tape filtering machine

A filter and paper belt technology, applied in the field of filtration, can solve the problems of large consumption of filter paper and low filtration capacity, and achieve the effect of reducing the floor space, increasing the filtration capacity, and increasing the filtration area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] If certain words are used to refer to specific components in the description and claims, those skilled in the art should understand that hardware manufacturers may use different terms to refer to the same component, and the description and claims do not rely on the difference in names As a way to distinguish components, but the difference in function of components is used as a criterion for distinction. For example, "comprising" mentioned in the entire specification and claims is an open term, so it should be interpreted as "comprising But not limited to", "approximately" means that within an acceptable error range, those skilled in the art can solve the technical problem within a certain error range and basically achieve the technical effect. However, the description is for the purpose of explaining the general principles of the present invention, and is not intended to limit the scope of the present invention. The scope of protection of the present invention should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com