Movable skid-mounted type organic solid waste treatment device

A technology for organic solid waste and treatment equipment, which is applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc. It can solve the problems that restrict the promotion and application of smoldering technology, and achieve convenience in situ The effect of off-site processing, low energy consumption, easy transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

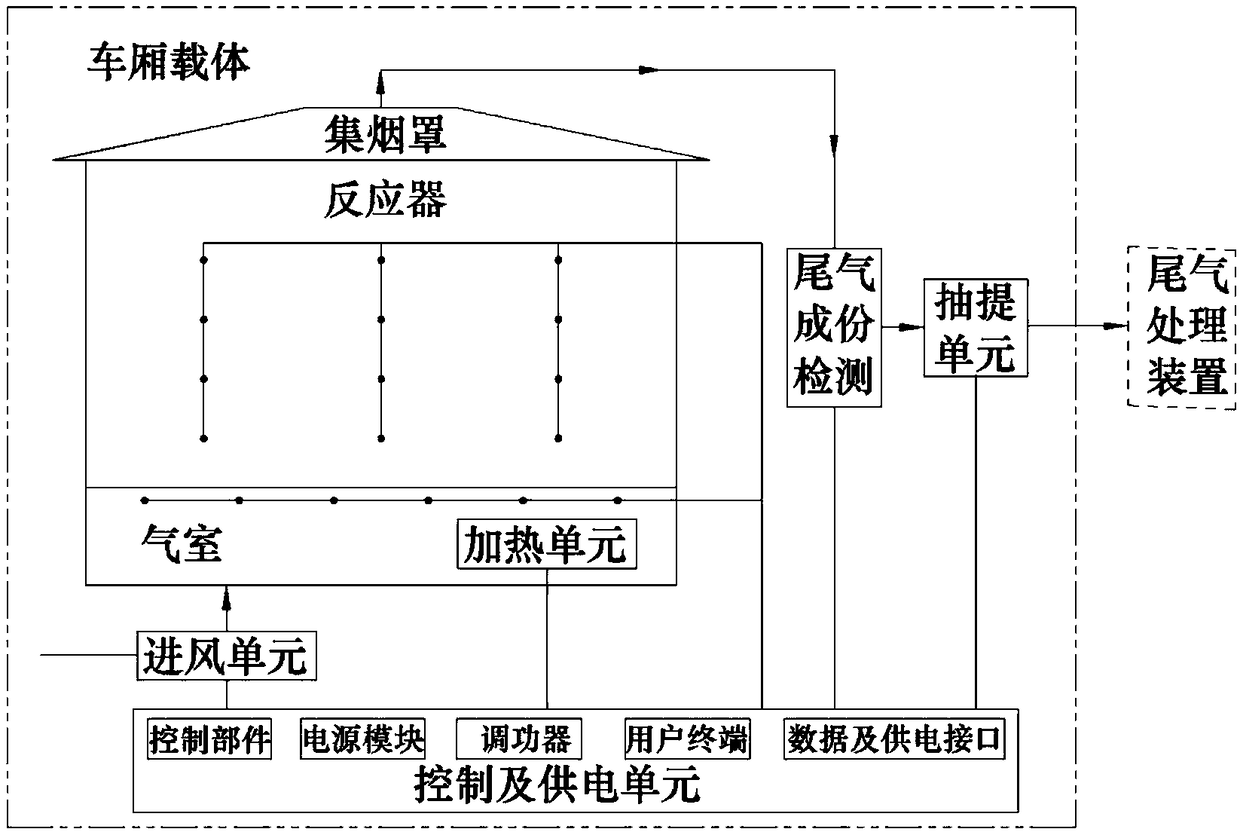

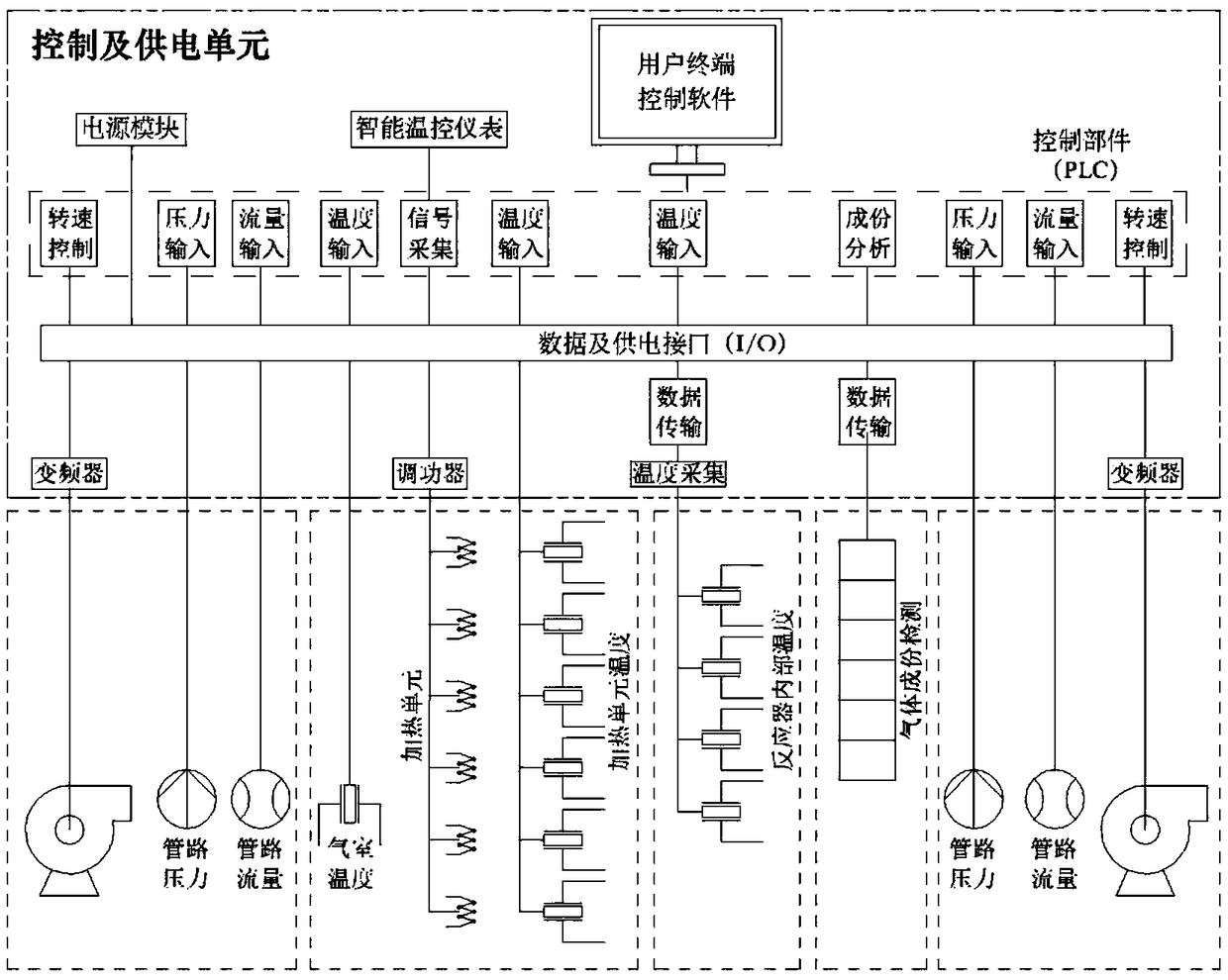

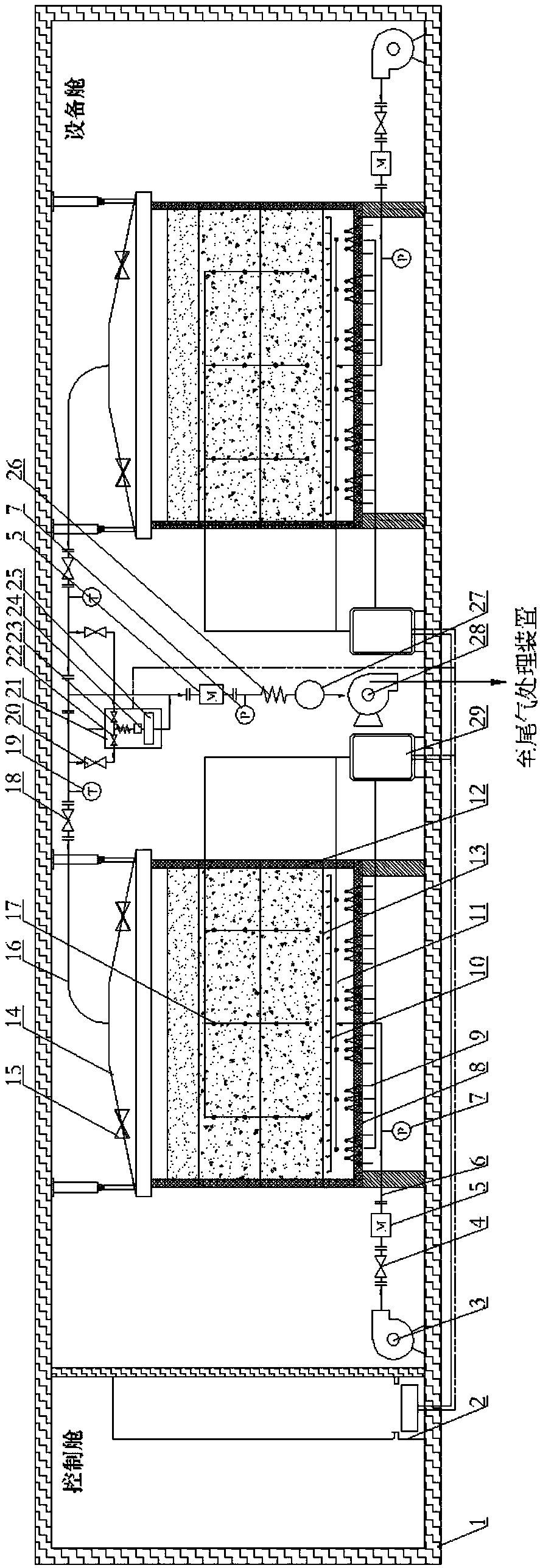

[0026] Example 1: In situ and ex situ soil thermal desorption restoration.

[0027] Use a vehicle to transport the device to the site and hoist it on a flat ground, and connect it to an external power source. The organic matter-contaminated soil that needs to be treated is packed in the reactor 12, according to the attached image 3As shown, each component unit is installed; according to the soil pollution component analysis report, the gas chamber temperature is set at the user terminal of the control and power supply unit 2, generally slightly higher than the highest pollutant boiling point temperature. Start the equipment, the air intake unit will deliver fresh air to the inside of the air chamber, and form a certain positive pressure inside, the heating unit 9 will heat the air inside the air chamber to the set temperature, and the control and power supply unit 2 will The collected temperature data controls the power of the heating unit 9, so that the temperature inside t...

Embodiment 2

[0028] Example 2: Utilize smoldering technology to treat petroleum pollutants (oil sludge).

[0029] Smoldering technology is a technology that uses organic pollutants in soil as self-sustaining fuel to carry out soil remediation through the principle of smoldering. The device can use smoldering technology to dispose of petroleum pollutants (oil sludge) in situ, such as tank bottom sludge and oil sludge near oil wells. Before the treatment, the petroleum pollutants (sludge) to be treated and the clean sand are uniformly stirred in a certain proportion, and the stirred petroleum pollutants (sludge) are put into the reactor 12 to ensure that the inside of the reactor 12 is smoldering Reaction continues, and avoids reactor 12 inside to produce naked flame, covers one deck clean sand above reactor 12 internal polluted soil (oil sludge), according to attached image 3 Install each component unit as shown. Start the equipment, the air intake unit will deliver fresh air to the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com