Adjustable device suitable for ultrasonic vibration cutting machining and application method of adjustable device

A vibration cutting and ultrasonic technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of long design and manufacturing cycle, difficult to meet processing requirements, difficult to realize in time, etc. Cutting efficiency and machining accuracy, the effect of design science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

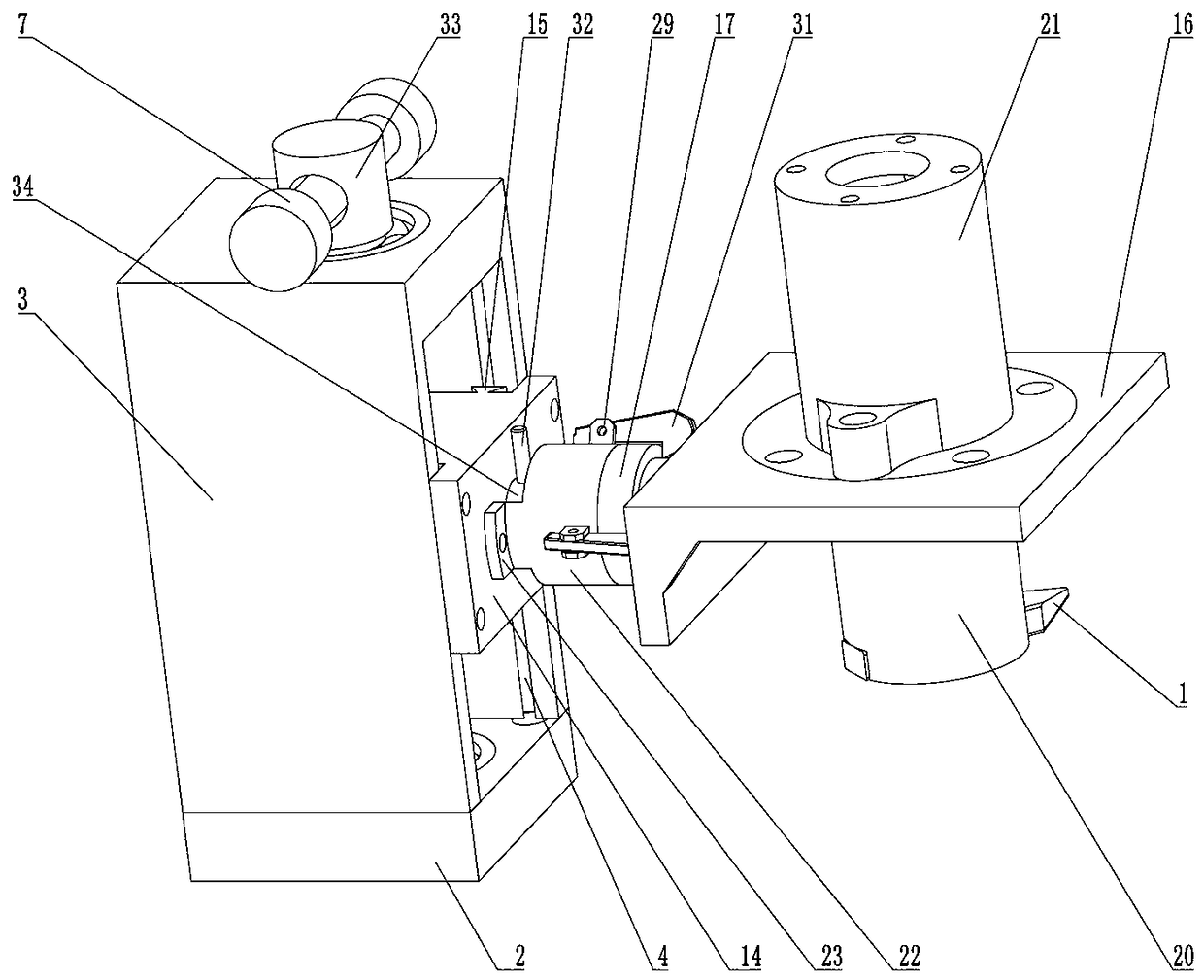

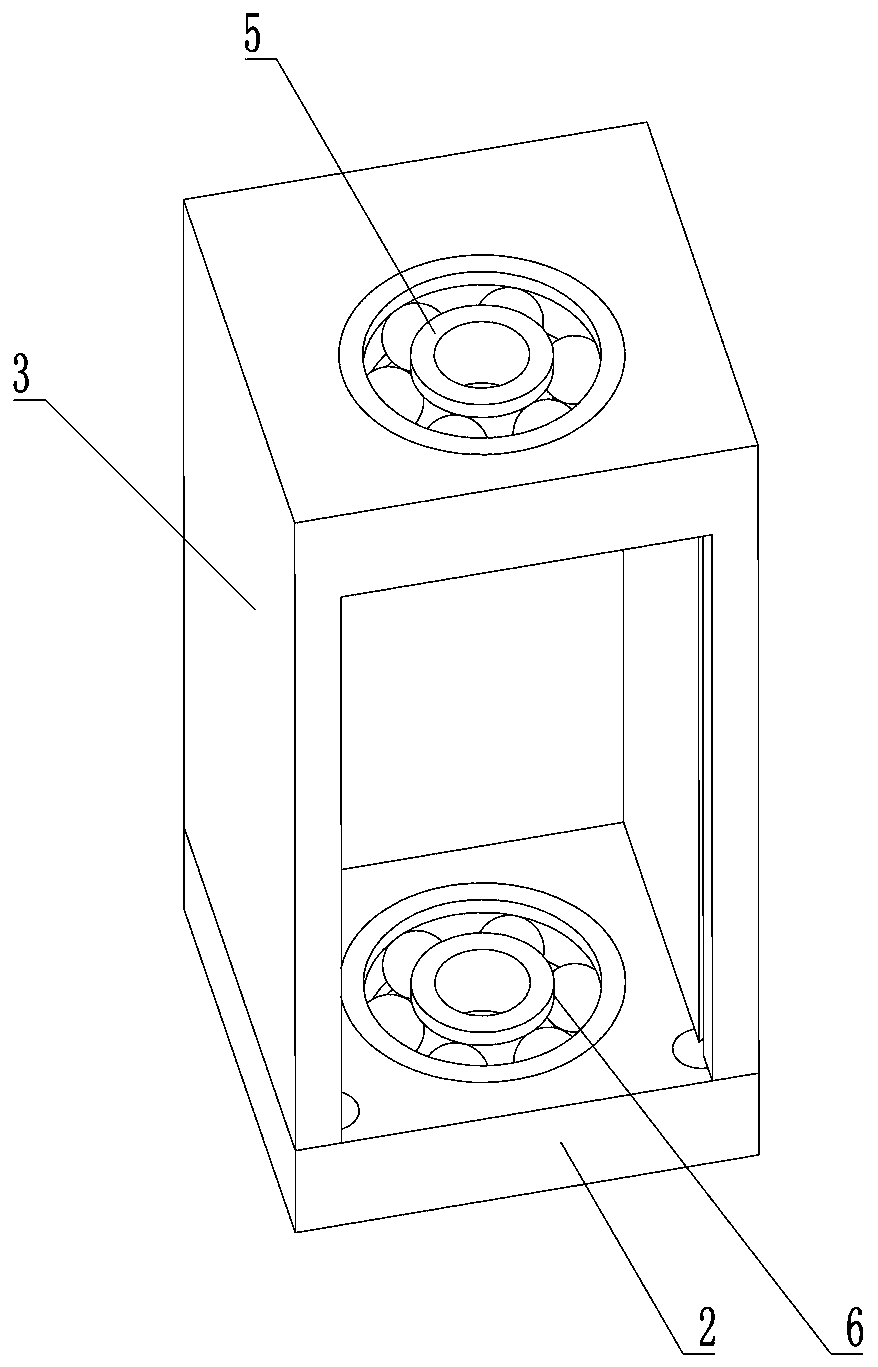

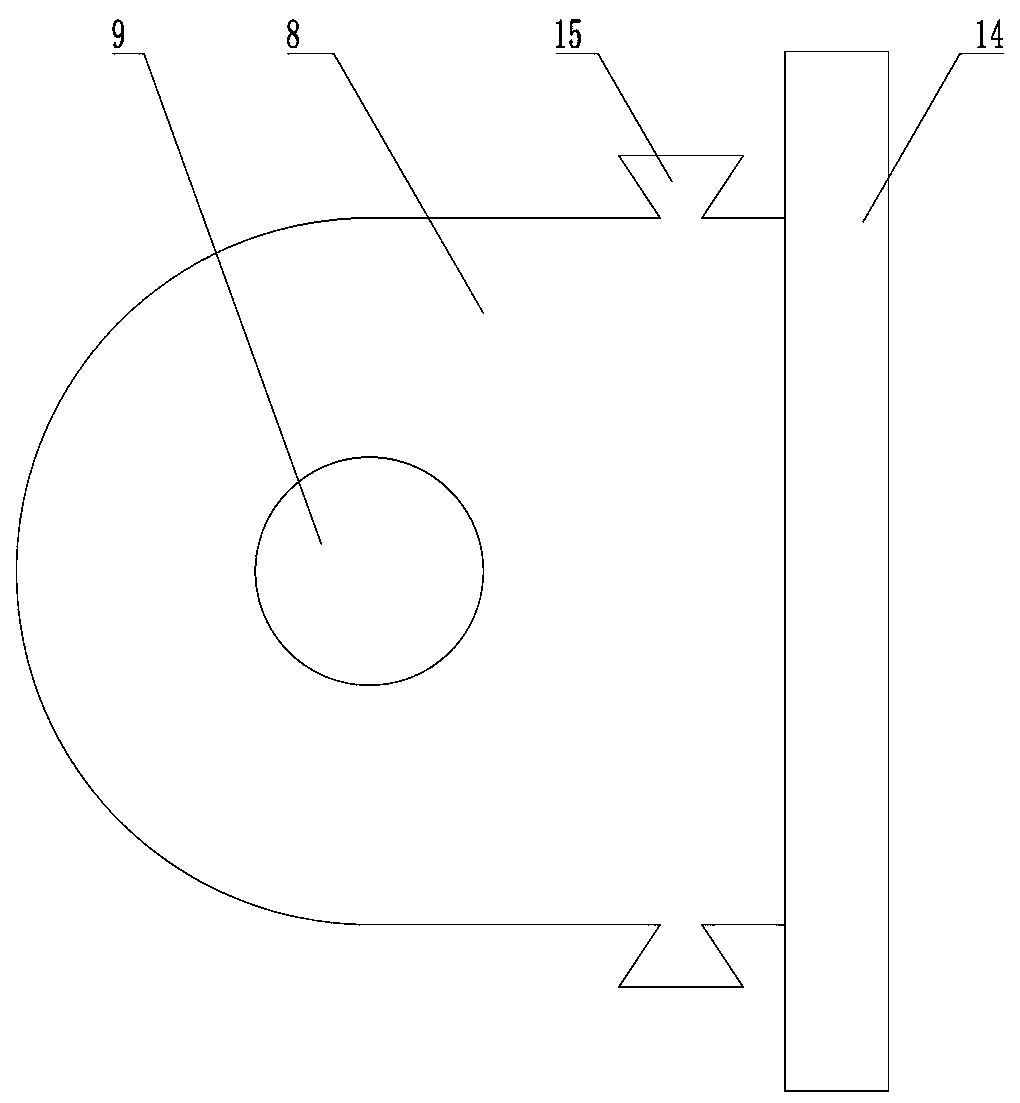

[0034] Such as Figure 1-Figure 12 As shown, it is suitable for an adjustable device for ultrasonic vibration cutting processing, including a tool 1 and a base 2. A vertically arranged door-shaped plate 3 is installed on the upper surface of the base 2. The front and rear sides of the door-shaped plate 3 and the base 2 are open. The tool lifting box, the tool 1 is located in front of the tool lifting box, a lifting mechanism is installed between the top plate of the door-shaped plate 3 and the base 2, and the front of the left and right sides of the door-shaped plate 3 is provided with a vertical The dovetail groove guide rail 4, the vertical dovetail groove guide rail 4 is slidingly installed with a lifting and moving seat, the rear end of the lifting and moving seat extends into the tool lifting box and is connected with the lifting mechanism, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com