Rapid tunnel lining concrete dismounting method

A concrete and tunnel technology, applied in tunnels, earthwork drilling, stone processing equipment, etc., can solve the problems of high strength of lining concrete, difficult demolition engineering, high safety risks, etc., to achieve improved construction efficiency, economic benefits, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0020] A method for quickly dismantling tunnel lining concrete, comprising the following steps:

[0021] Step 1, making an automatic circumcision trolley.

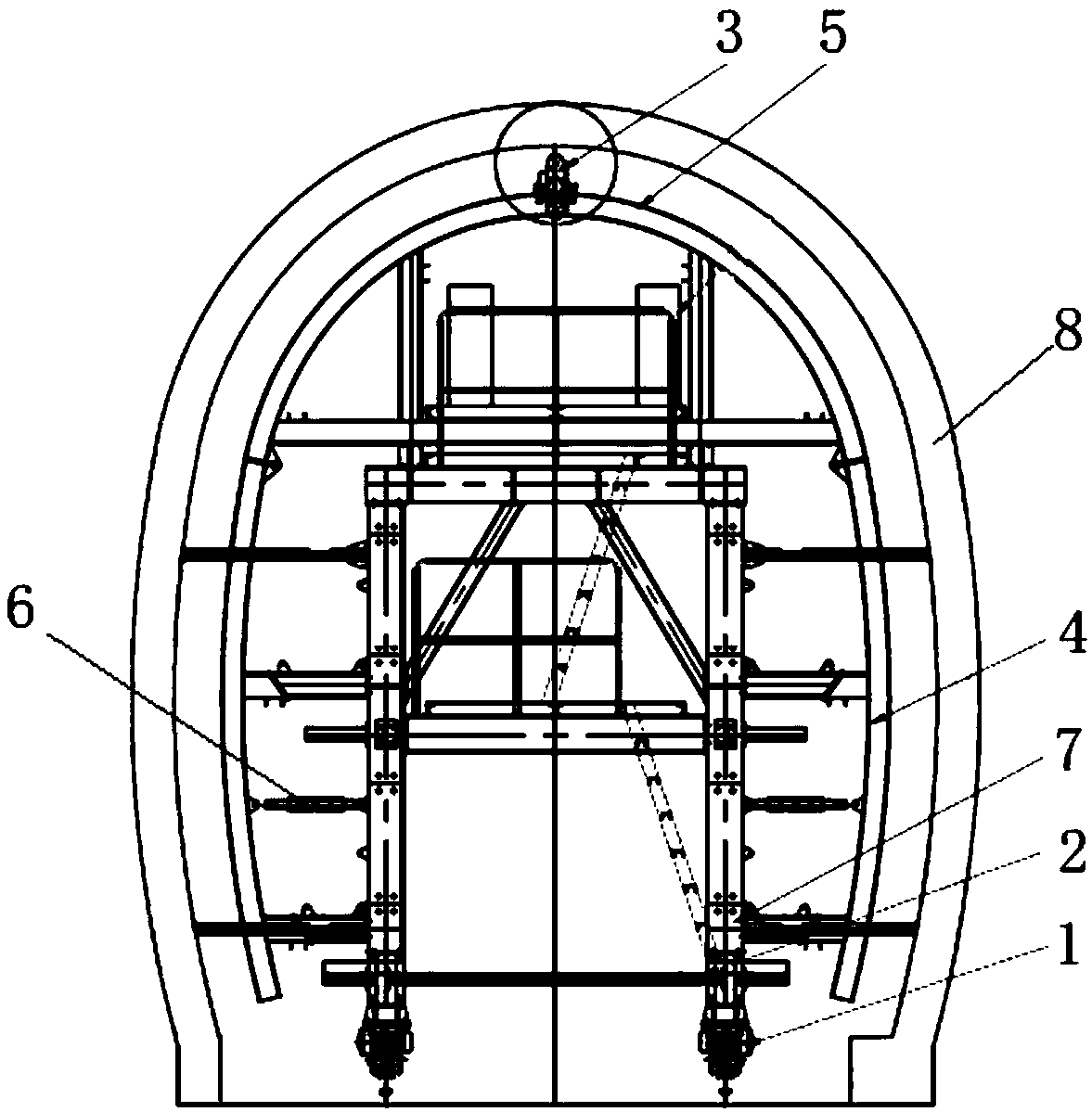

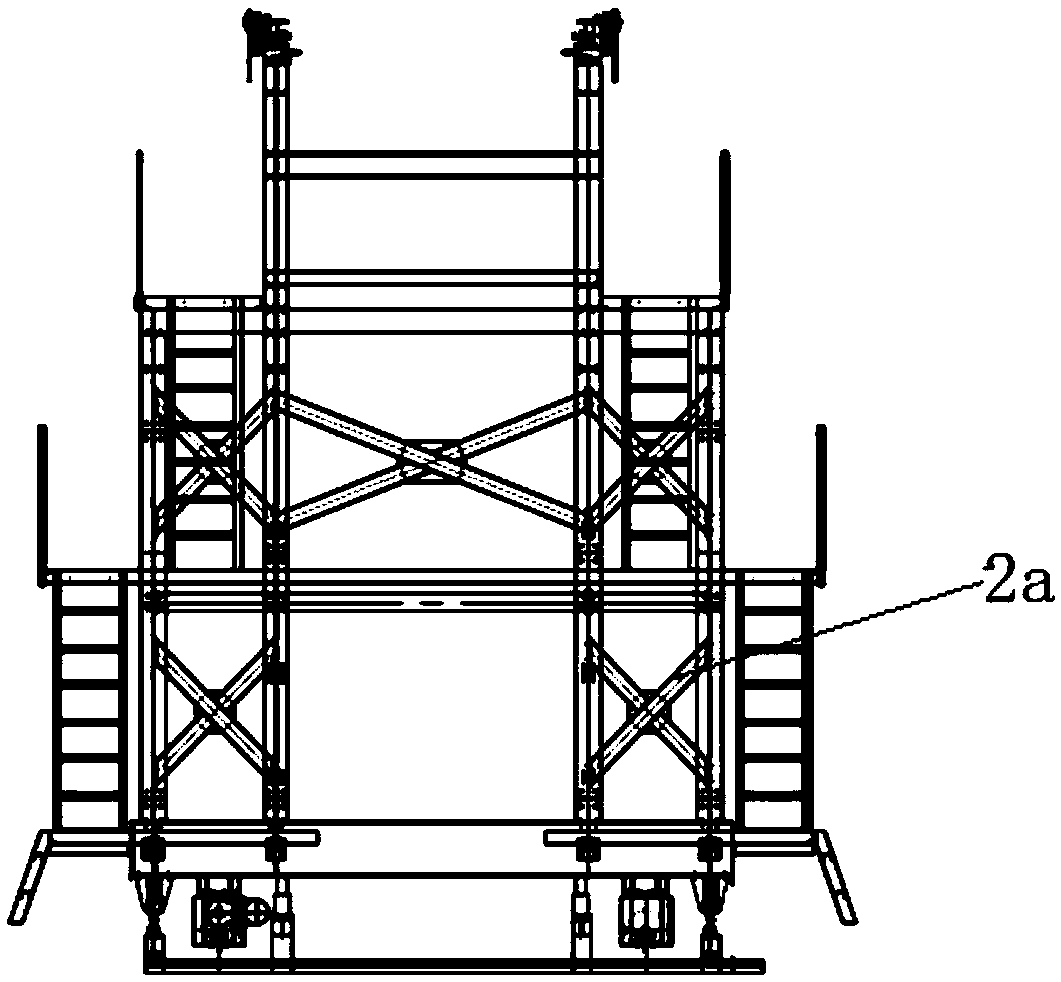

[0022] Such as figure 1 — figure 2 As shown, the automatic circular cutting trolley is mainly composed of a traveling mechanism 1, a stand 2, a wall saw machine 3, an arch support frame 4, an arc track 5, a horizontal jack 6, and a vertical jack 7.

[0023] The traveling mechanism 1 is arranged under the stand 2, and is used to realize the automatic walking of the automatic circumcision trolley. The rail trolley can be used as the running mechanism below the stand 2, and the automobile with rubber tires can also be used as the running mechanism. The stand 2 can be stretched left and right and up and down, and the trolley used in the tunnel can usually be stretched left and right and up and down i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com