Preparation method for early strength alkali-free liquid accelerator

A technology of quick-setting agent and early-strength type, applied in the field of early-strength alkali-free liquid quick-setting agent and its preparation, can solve the problems of concrete strength and durability decline, damage to human health, corrosion damage to construction workers, etc. The effect of good sexuality and probability reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

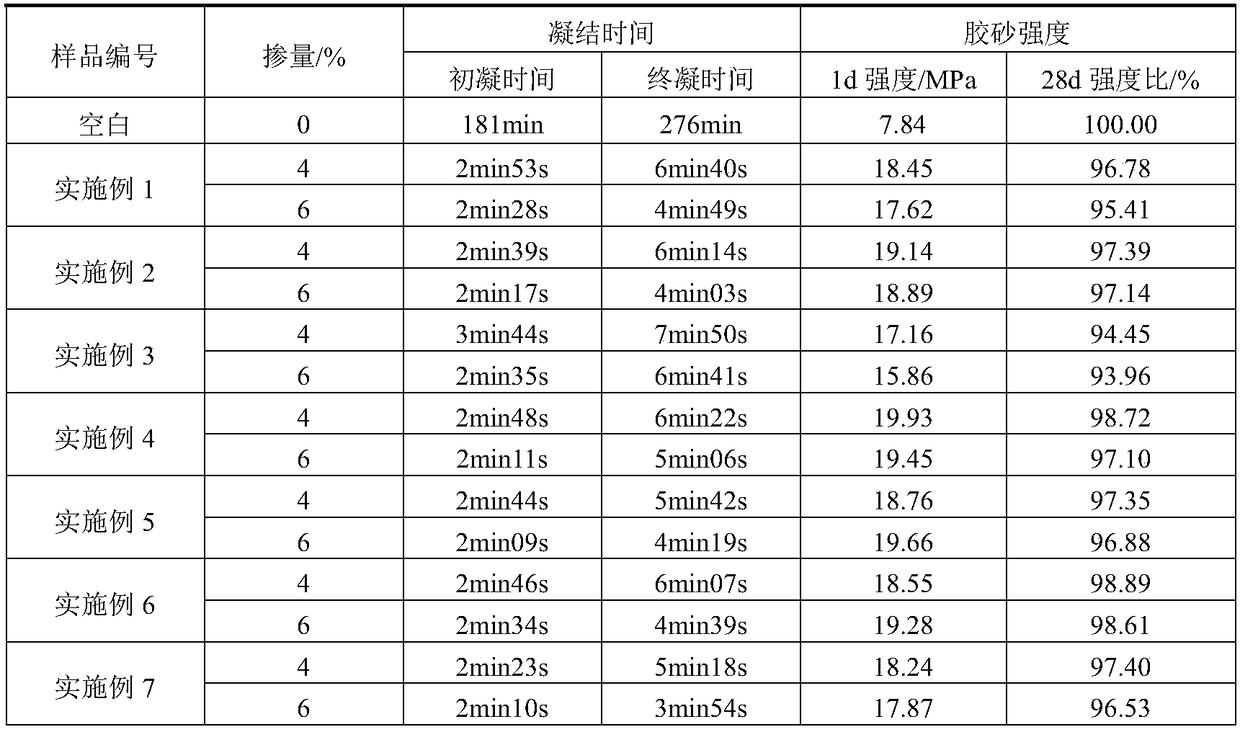

Examples

Embodiment 1

[0022] A preparation method of an early-strength type non-alkali liquid quick-setting agent, comprising the following steps:

[0023] (1) The preparation method of modified alcohol amine: Add alcohol amine, amine organic matter and catalyst into a 250ml four-necked bottle equipped with a mechanical stirring device, a circulating condensing device, and a thermometer, and the molar ratio is 1:3:0.005. After reacting at ℃ for 1 hour, add 2 mol of organic acid to the obtained mixed solution to react for 0.5 hour to obtain modified alcohol amine;

[0024] (2) Preparation of early-strength non-alkali liquid quick-setting agent: first place 60g of aluminum sulfate, 6g of magnesium sulfate and 6g of organic acid in a three-necked flask, then add 30g of deionized water, and heat it at 400r / h under a constant temperature water bath at 80°C. min and stirred for 1.5h to obtain the quick-setting agent mother liquor; in a constant temperature water bath at 65°C, stirred at 350r / min, then ad...

Embodiment 2

[0035] A preparation method of an early-strength type non-alkali liquid quick-setting agent, comprising the following steps:

[0036] (1) Preparation method of modified alcohol amine: add alcohol amine, amine organic matter and catalyst into a 250ml four-necked bottle equipped with a mechanical stirring device, a circulating condensing device, and a thermometer, and the molar ratio is 1:2.5:0.0045. After reacting at 65°C for 1.5 hours, add 3 mol of organic acid to the obtained mixed solution to react for 45 minutes to obtain modified alcoholamine;

[0037] (2) Preparation of early-strength non-alkali liquid quick-setting agent: first place 75g of aluminum sulfate, 8g of magnesium sulfate and 5g of organic acid in a three-necked flask, then add 19g of deionized water, and heat it at 400r / h under a constant temperature water bath at 80°C. Stir for 2 hours to obtain the quick-setting agent mother liquor; in a constant temperature water bath at 65°C, stir at 400r / min, then add 10g...

Embodiment 3

[0048] A preparation method of an early-strength type non-alkali liquid quick-setting agent, comprising the following steps:

[0049] (1) Preparation method of modified alcohol amine: add alcohol amine, amine organic matter and catalyst into a 250ml four-necked bottle equipped with a mechanical stirring device, a circulating condensing device, and a thermometer, and the molar ratio is 1:3:0.01. After reacting at 75°C for 1 hour, add 3 mol of organic acid to the obtained mixed solution to react for 45 minutes to obtain modified alcohol amine;

[0050] (2) Preparation of early-strength non-alkali liquid quick-setting agent: first place 85g of aluminum sulfate, 10g of magnesium sulfate and 5g of organic acid in a three-necked flask, then add 20g of deionized water, and heat it at 400r / h under a constant temperature water bath at 85°C. Stir for 2 hours to obtain the quick-setting agent mother liquor; in a constant temperature water bath at 70°C, stir at 400r / min, then add 10g of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com