A kind of preparation method of early-strength type non-alkali liquid quick-setting agent

A technology of quick-setting agent and early-strength type, which is applied in the field of early-strength alkali-free liquid quick-setting agent and its preparation, and can solve the problems such as the decrease of concrete strength and durability, the low early strength of the quick-setting agent, and the corrosion damage of construction personnel. , to achieve the effect of reducing the possibility and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

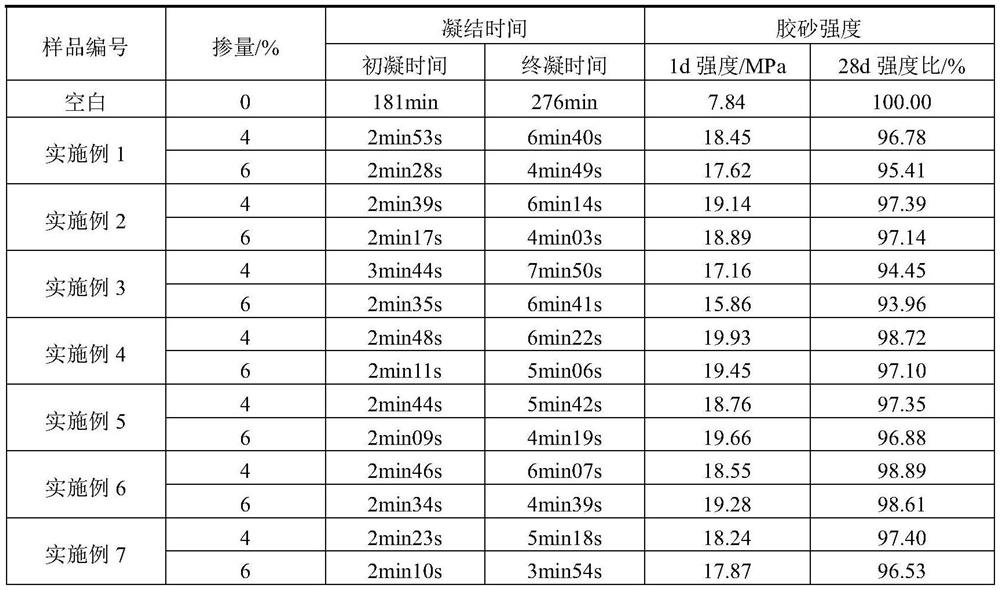

Examples

Embodiment 1

[0022]A preparation method of an early-strength alkali-free liquid quick-setting agent, comprising the following steps:

[0023](1) Preparation method of modified alcohol amine: Add alcohol amine, amine organics and catalyst into a 250ml four-necked flask equipped with mechanical stirring device, circulating condensation device and thermometer, the molar ratio of which is 1:3:0.005, at 65 After reacting at °C for 1 hour, add 2 mol of organic acid to the resulting mixed solution and react for 0.5 hours to obtain a modified alcohol amine;

[0024](2) Preparation of early-strength alkali-free liquid quick-setting agent: first put 60g of aluminum sulfate, 6g of magnesium sulfate and 6g of organic acid in a three-necked flask, then add 30g of deionized water, at a temperature of 400r / Min stirring for 1.5h to obtain the accelerator mother liquor; stir at 350r / min under a constant temperature water bath at 65℃, and then add 6g of the modified alcohol amine obtained in step (1) to the accelerato...

Embodiment 2

[0035]A preparation method of an early-strength alkali-free liquid quick-setting agent, comprising the following steps:

[0036](1) Preparation method of modified alcohol amine: Add alcohol amine, amine organics and catalyst into a 250 ml four-necked flask equipped with a mechanical stirring device, a circulating condensation device and a thermometer. The molar ratio of the alcohol amine, amine organics and catalyst is 1:2.5:0.0045. After reacting at 65°C for 1.5 hours, add 3 mol of organic acid to the resulting mixed solution to react for 45 minutes to obtain a modified alcohol amine;

[0037](2) Preparation of early-strength alkali-free liquid quick-setting agent: first put 75g aluminum sulfate, 8g magnesium sulfate and 5g organic acid in a three-necked flask, then add 19g deionized water, at a temperature of 400r / Min stirring for 2h to obtain the accelerator mother liquor; stir at 400r / min under a constant temperature water bath at 65°C, then add 10g of the modified alcohol amine obta...

Embodiment 3

[0048]A preparation method of an early-strength alkali-free liquid quick-setting agent, comprising the following steps:

[0049](1) Preparation method of modified alcohol amine: Add alcohol amine, amine organics and catalyst into a 250 ml four-necked flask equipped with mechanical stirring device, circulating condensation device and thermometer, the molar ratio of which is 1:3:0.01. After reacting at 75°C for 1 hour, add 3 mol of organic acid to the resulting mixed solution to react for 45 minutes to obtain a modified alcohol amine;

[0050](2) Preparation of early-strength alkali-free liquid quick-setting agent: first put 85g aluminum sulfate, 10g magnesium sulfate and 5g organic acid in a three-necked flask, and then add 20g deionized water, at a constant temperature of 85 ℃ water bath at 400r / Min stirring for 2h to obtain the accelerator mother liquor; stir at a constant temperature of 70℃ in a water bath at 400r / min, then add 10g of the modified alcohol amine obtained in step (1) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com