Nano-micron composite concrete powder early strength agent and preparation method thereof

An early-strength agent and composite technology, which is applied in the field of preparation of nano-micron composite concrete powder early-strength agent, can solve the problems of large surface energy, gel, and difficult to separate from each other, so as to improve the early strength and reduce the use of cost, the effect of increasing the reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

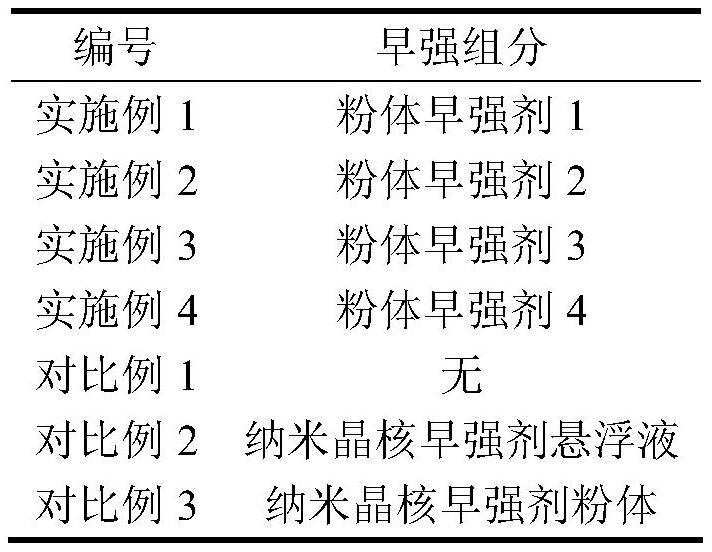

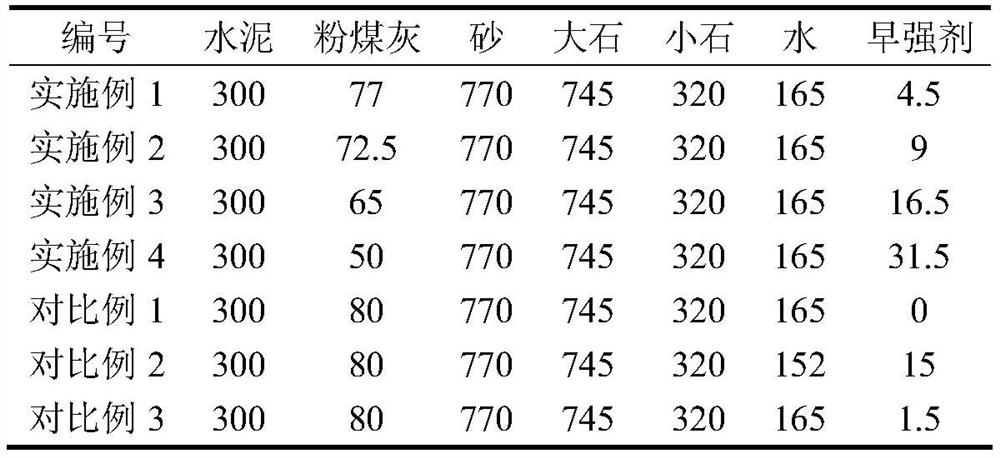

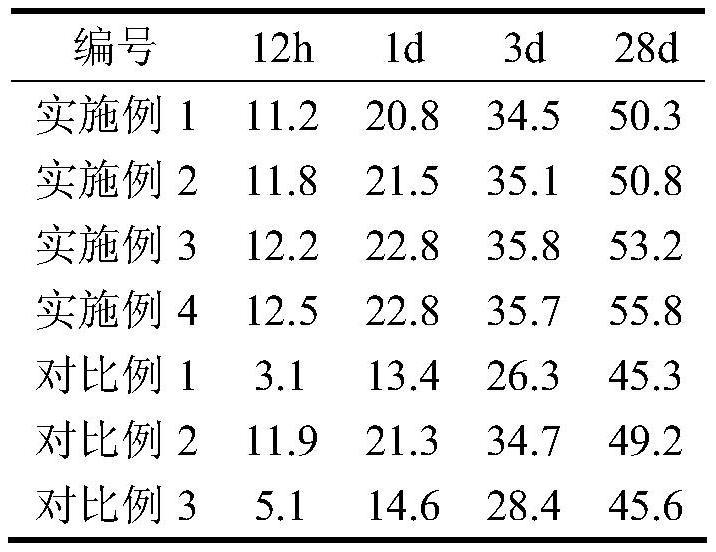

Examples

Embodiment 1

[0025] (1) Mix and stir the fly ash and alkali solution for modification, then filter the mixture with suction, wash, dry, and pass through a 45 μm sieve after cooling; -511 super-early-strength admixture was spray-dried, the drying time was 10s, and it was ground in a planetary ball mill for 5 minutes; (3) The dry powder of fly ash and nano-crystal nucleus early-strength agent was put into Nara, Japan according to the mass ratio of 1:0.5 The powder early strength agent 1 was obtained by compound treatment in the HYB equipment manufactured by the Machinery Manufacturing Institute, the rotation speed was 10000r / min, and the treatment time was 5min.

Embodiment 2

[0027] (1) Mix and stir the fly ash and alkali solution and modify it with ultrasonic dispersion, then filter the mixture with suction, wash, dry, and pass through a 45 μm sieve after cooling; (2) Mix the commercially available nanocrystalline nucleus strong agent -511 super-early-strength admixture was spray-dried, the drying time was 10s, and it was ground in a planetary ball mill for 10 minutes; (3) The dry powder of fly ash and nano-crystal nucleus early-strength agent was put into Nara, Japan according to the mass ratio of 1:0.2 The powder early strength agent 2 was obtained by compound treatment in the HYB equipment manufactured by the Machinery Manufacturing Institute, the rotation speed was 8000r / min, and the treatment time was 6min.

Embodiment 3

[0029] (1) Mix and stir fly ash and alkali solution and react in microwave for modification, then filter the mixture with suction, wash, dry, and pass through a 45 μm sieve after cooling; (2) Mix commercially available nanocrystalline nuclei early strength agent -511 super-early-strength admixture was spray-dried, the drying time was 10s, and it was ground in a planetary ball mill for 10 minutes; (3) The dry powder of fly ash and nano-crystal nucleus early-strength agent was put into Nara, Japan according to the mass ratio of 1:0.1 The powder early strength agent 3 was obtained by compound treatment in the HYB equipment manufactured by the Machinery Manufacturing Institute, the rotation speed was 5000r / min, and the treatment time was 8min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com