Early-strength water reducing agent for machine-made sand concrete prestressed component and preparation method thereof

A concrete and prestressing technology, applied in the field of early-strength superplasticizer for prestressed components of machine-made sand concrete and its preparation field, can solve the problems of low strength of superplasticizer, poor adaptability of machine-made sand concrete, etc. Cement hydration speed, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

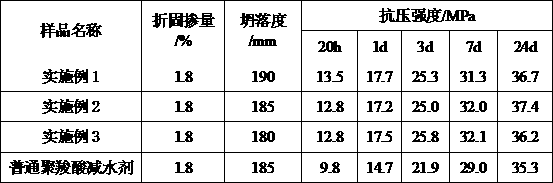

Examples

Embodiment 1

[0027] An early-strength water-reducing agent for machine-made sand concrete prestressed components, composed of raw materials of the following weights: acrylic acid 41g, acrylamide 10g, sodium methacrylate 5g, polyethylene glycol diacrylate 15g, vitamin C 0.7 g. Mercaptopropionic acid 2.0g, methallyl polyoxyethylene ether monomer with a molecular weight of 4000 365g, hydrogen peroxide 4.0g with a concentration of 27.5wt% and deionized water 530g, the deionized water includes the first part 100g of ionized water, 80g of the second portion of deionized water, 100g of the third portion of deionized water, and 250g of the fourth portion of deionized water.

[0028] The preparation method includes the following steps:

[0029] (1) Add 41g acrylic acid, 10g acrylamide, 5g sodium methacrylic acid sulfonate and 100g deionized water in sequence to obtain mixed solution A, which is ready for use;

[0030] (2) Mix 15 g of polyethylene glycol diacrylate and 80 g of deionized water to obtain mi...

Embodiment 2

[0035] An early-strength water-reducing agent for machine-made sand concrete prestressed components, which is composed of raw materials of the following weights: acrylic acid 36g, acrylamide 8g, sodium methacrylate 3g, polyethylene glycol diacrylate 10g, heptahydrate and Ferrous sulfate 0.15g, mercaptoethanol 0.5g, molecular weight 5000 methallyl polyoxyethylene ether monomer 365g, ammonium persulfate 1.8g and deionized water 530g, the deionized water includes the first part of deionized water 100g of water, 80g of the second portion of deionized water, 100g of the third portion of deionized water, and 250g of the fourth portion of deionized water.

[0036] The preparation method includes the following steps:

[0037] (1) Add 36g acrylic acid, 8g acrylamide, 3g sodium methacrylic acid sulfonate and 100g deionized water in sequence to obtain mixed solution A, which is ready for use;

[0038] (2) Mix 10g polyethylene glycol diacrylate and 80g deionized water to obtain mixed solution B...

Embodiment 3

[0043] An early-strength water-reducing agent for machine-made sand concrete prestressed components, consisting of raw materials of the following weights: acrylic acid 34g, acrylamide 8g, sodium methacrylic acid 2g, polyethylene glycol diacrylate 15g, vitamin C 0.7 g. Mercaptoethanol 2.4g, methallyl polyoxyethylene ether monomer with a molecular weight of 6000 365g, ammonium persulfate 1.5g and deionized water 500g, the deionized water includes the first part of deionized water 100g, the first part Two parts of deionized water 80g, the third part of deionized water 100g and the fourth part of deionized water 220g.

[0044] The preparation method includes the following steps:

[0045] (1) Add 34g acrylic acid, 8g acrylamide, 2g sodium methacrylic acid sulfonate and 100g deionized water in sequence to obtain mixed solution A, which is ready for use;

[0046] (2) Mix 15 g of polyethylene glycol diacrylate and 80 g of deionized water to obtain mixed solution B for use;

[0047] (3) Mix 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com